Renew Canada Magazine's 2026 Top 100 Biggest Infrastructure Projects Report is out—and we’re proud to see that 14 projects we’re supporting are being recognized for shaping a better Canada.

From hospitals and health campuses to complex institutional facilities, these significant projects reflect the scale, collaboration, and innovation HH Angus is helping to deliver across the country.

Our deep portfolio of designing and building key infrastructure in Canada ranges from hospitals and correctional facilities to municipal buildings and transit, across a range of project delivery models. Congratulations to our colleagues, clients and project partners driving these landmark developments forward!

Here’s an at-a-glance list of the projects we are proud to be involved with in the 2026 Top 100 list.

4|

Peter Gilgan Mississauga Hospital

(Trillium Health Partners)

TBeing delivered as a Progressive Design Build, the Peter Gilgan Mississauga Hospital will be a full replacement of an existing facility, span 22 floors and approximately 2.8 million ft2 and include over 950 beds, 23 operating rooms, a new and expanded Emergency Department, advanced diagnostic imaging facilities, new pharmacy and a new clinical laboratory. HH Angus is providing mechanical engineering and conveyance consulting services. It is being delivered through a Progressive Design Build model.

Image Courtesy of Infrastructure Ontario

11|

QEII Health Sciences Centre Redevelopment

This redevelopment is a multi-phase project that involves the renovation of Hants Community Hospital in Windsor, renovation of Dartmouth general Hospital, a new Community Outpatient Centre in Bayers Lake, expansion of the Halifax Infirmary site, a new hospice residence, and relocation of the QEII Cancer centre to the new Infirmary site. HH Angus provided mechanical engineering consulting services for the Bayers Lake Community Outpatient Centre which opened in 2023.

26|

South Niagara Hospital

The new South Niagara Hospital will be a full acute care hospital with 24/7 Emergency Department, diagnostic, therapeutic, and surgical services. The latter will include medical, surgical, and intensive care inpatient beds. Also included will be ambulatory services; post-acute Complex Continuing Care (CCC) Inpatient services; and Centres of Excellence specializing in stroke, complex care, geriatric/psychogeriatrics, and wellness in aging. The facility is targeting LEED Silver certification and is being designed to be Canada’s first WELL-certified healthcare facility. HH Angus is providing mechanical engineering and conveyance systems (AGVs, AMRs and vertical transportation) consulting services.

Image Courtesy of Infrastructure Ontario

32|

Surrey Hospital and BC Cancer Centre

The New Surrey Hospital and BC Cancer Centre will provide 168 hospital beds and 55 Emergency Department treatment spaces in a state-of-the-art facility to improve health services in the region. Leading BC's first generation of smart hospitals, the new hospital will embed data insights and new technologies into both the design of the facility and delivery of clinical care – the first of its kind in BC. HH Angus is providing a full spectrum of ICAT/IMIT design and AGV consulting, and our Vertical Transportation team is designing the elevator systems.

34|

The Ottawa Hospital Civic Campus Development

Being delivered using the Progressive P3 approach, the new campus development will be one of the largest and most modern teaching hospitals in Canada. It’s slated to open in 2028, and will serve Ottawa, Eastern Ontario, Western Quebec and parts of Nunavut. HH Angus is providing mechanical engineering and conveyance systems (AGVs and vertical transportation) consulting services.

Image Courtesy of HDR

40|

New Hospital for Sick Children

SickKids’ Project Horizon is a three-phase redevelopment project to rebuild and rehabilitate their existing downtown Toronto healthcare campus. Angus Connect, a division of HH Angus, was engaged to develop a comprehensive digital strategy and ICAT roadmap to support Project Horizon and help SickKids understand their organizational and technology needs today and those anticipated for the future.

41|

Burnaby Hospital Redevelopment

Burnaby Hospital is undergoing a massive redevelopment through two phases. HH Angus is providing electrical and IMIT design consulting services for Phase 2 of the redevelopment which involves a new inpatient tower, medical imaging department, renovations to emergency and endoscopy departments and a new integrated BC Cancer Centre. The project is being delivered through an Alliance model.

Image courtesy of Fraser Health Authority

44|

St. Paul’s Hospital Redevelopment

The new St. Paul’s Hospital redevelopment in downtown Vancouver will provide 548 beds and include an emergency department, critical care and surgical suites, mental health and additional facilities, maternity, rehabilitation, and inpatient care facilities. Angus Connect, a division of HH Angus, is providing AGV compliance consulting services to the project.

Image Courtesy of Providence Health Care

61|

Royal Columbian Hospital, Phases 2 & 3

The Royal Columbian Hospital is the oldest hospital in the province of B.C. The three-phase redevelopment project will see a major expansion of the acute care campus with upgrades to critical infrastructure, increasing the hospital’s capacity by 50%. HH Angus is providing mechanical and electrical engineering and IMIT and vertical transportation consulting services for all three phases in a compliance role.

Image courtesy of Fraser Health Authority

62|

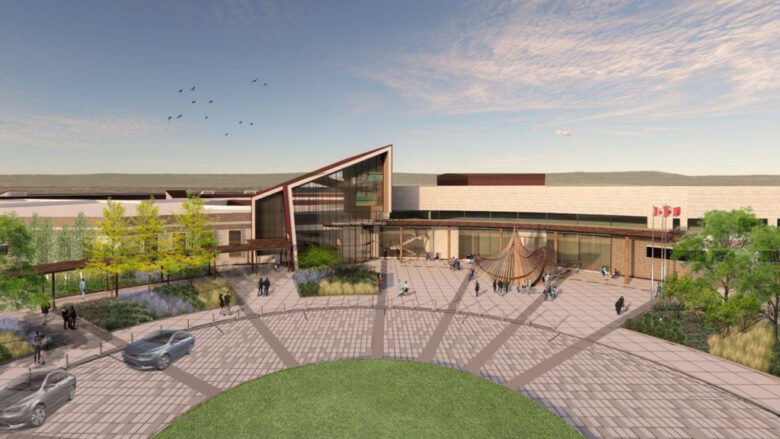

Quw’utsun/Cowichan Hospital Redevelopment

Being delivered through an Alliance approach, the project involves replacement of the existing community acute care hospital with a new 607,000 ft2, 204-bed facility that will also include mental health facilities featuring a 20-bed inpatient unit and dedicated ICU, culturally safe services and spaces, 7 operating rooms, increased CT scanning capacity, and built-in MRI facilities. It will also be the first fully electric hospital in BC and Canada’s first CaGBC Net Zero Carbon hospital. HH Angus is providing mechanical and electrical consulting engineering services. It is being delivered through an Alliance model.

66|

Gilgan Family Queensway Health Centre, Trillium Health Partners

The 600,000-square-feet Gilgan Family Queensway Health Centre P3 will include a new patient tower, including a modern nine-story facility with over 350 beds and fully private patient rooms to ensure privacy and enhance infection prevention control. The expanded space will also allow TPH to connect more people to specialized care, including complex continuing care and rehabilitation services. Angus Connect is providing ICAT systems consulting services to the project.

Image Courtesy of Trillium Health Partners

69|

Thunder Bay Correctional Complex

This new correctional facility is 450,000 ft2 in size and includes 345 beds and features dedicated Indigenous cultural spaces, such as smudging space and sweat and teaching lodges. It is targeting LEED Silver and LEED Resilient Design certification. HH Angus is providing mechanical engineering and vertical transportation consulting services.

Image Courtesy of Infrastructure Ontario

72|

Toronto Western Hospital Patient

& Surgical Tower

University Health Network’s (UHN) new $1 billion, 15-storey patient care and surgical tower will be built on Toronto Western Hospital’s (TWH) campus in downtown Toronto and enhance UHN’s capabilities caring for complex neurological and orthopedic cases. The new facility will be over 380,000 ft2 in size over 15-storeys and include 11 clinical program floors, 82 beds, and 20 operating rooms of which three will be hybrid ORs with cutting-edge imaging capabilities as well as featuring many of the latest healthcare technological advancements. HH Angus is providing mechanical engineering, electrical engineering, and ICAT/IMIT consulting services.

Image Courtesy of DIALOG

98|

Cape Breton Regional Hospital Expansion

The Cape Breton Regional Hospital is undergoing its first major expansion since it was first built and is part of Cape Breton Regional Municipality’s comprehensive upgrade of healthcare facilities in the wider Sidney area. The project involves a new 320,000 ft2 clinical services building that will house a new and larger emergency department, critical care department, additional inpatient beds, surgical suites, maternity ward and a cardiac catheterization lab. There will also be a new 96,000 ft2 cancer centre and a new energy centre. HH Angus is providing Operational Readiness services.

Explore the full Top 100 list here

Click HH Angus – ReNew Canada to learn more about our projects in this year’s report.