Digital Twin opportunities have increased dramatically given the advancement in technologies used to design, build and operate complex environments.

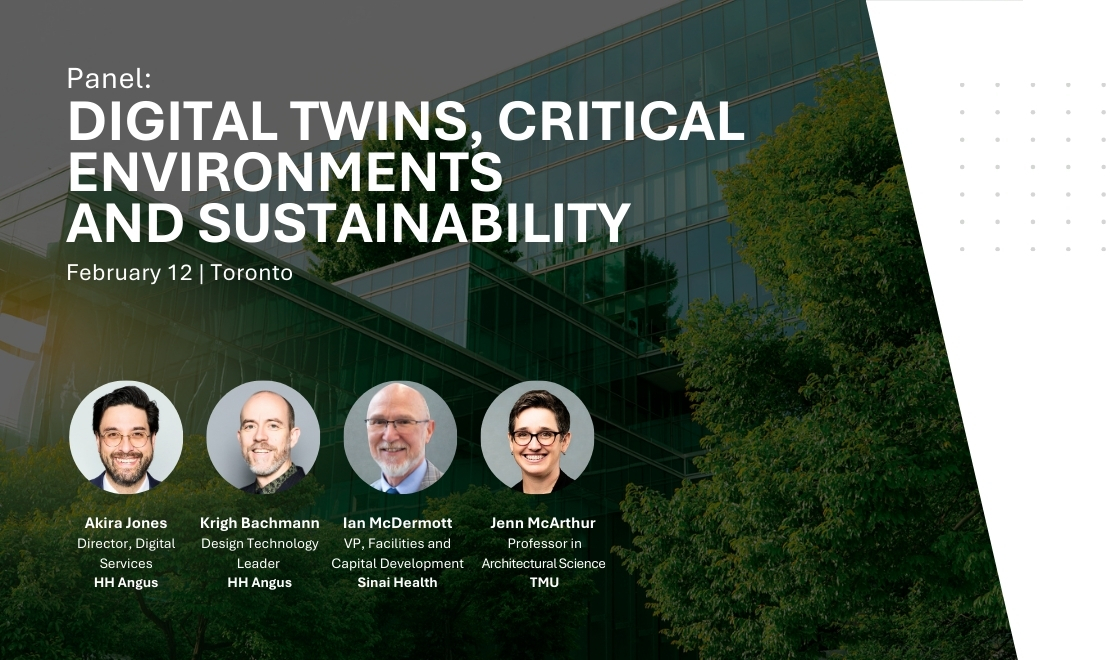

On February 12 in Toronto, HH Angus’ Akira Jones and Krigh Bachmann are taking part in an SLCan Toronto panel, sharing their expertise at the intersection of digital twins, critical environments, and sustainability. Also on the panel are Ian McDermott - Vice President, Facilities and Capital Development, Sinai Health and former president of Sustainable Labs Canada, and Jenn McArthur - Professor in Architectural Science, TMU, offering owner and academic perspectives to round out this dynamic conversation.

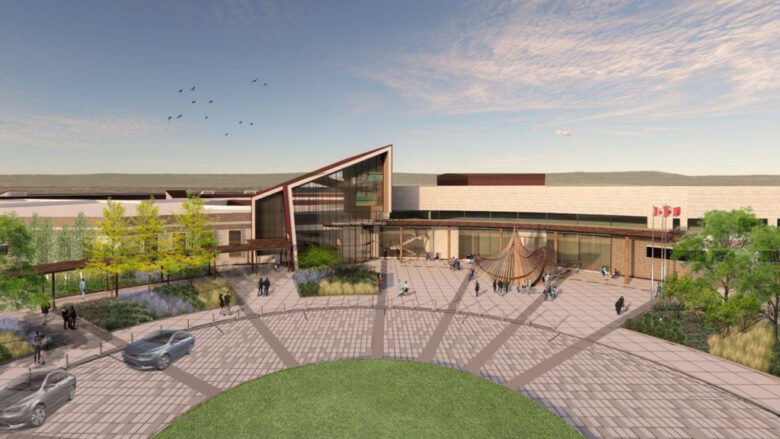

Akira and Krigh bring deep experience in applying digital twin technologies, smart building systems, and advanced design and delivery strategies to help organizations improve performance, resilience, and long-term sustainability—particularly in complex environments like laboratories and healthcare facilities.

The discussion will explore how digital twins have evolved—given the advance in technologies used to design, build and operate complex environments, where systems have matured from static models to real-time, predictive, and autonomous systems. The panel will also be discussing what can be done to create new and more sustainable laboratories, and how to make existing laboratories more sustainable.

Learn more / Register: SLCan Toronto - Knowledge & Networking Event | SLCan / LÉCan