Part One: Heat Pump Technology and Why We Need it

Building owners who are heating and cooling with fossil fuel energy sources are increasingly looking for solutions to reduce their buildings reliance on these fuels. This particularly applies to people-oriented buildings, such as commercial, institutional, and condo/multifamily residential buildings. Heat pump technology has come a long away in recent years; today, heat pumps are highly efficient, operate on electricity and can operate effectively in colder climates. While electricity is expensive, careful analysis reveals a heat pump solution can be more cost-effective than using natural gas. Heat pumps are also more efficient, have lower operating costs and will help owners looking to achieve net zero and significantly reduce their portfolio’s CO2 emissions. Heat pumps can also save on water use if using ground source heat pumps – more on this below.

Climate change is one of the most important challenges of our time. Buildings account for 39% of energy-related CO2 emissions on an annual basis globally1 and building operations (heating, cooling, lighting) account for 28% of emissions annually2. Lowering carbon emissions from buildings is an important element in fighting climate change. In the near future, heating buildings with fossil fuels will increasingly cease to be an option as the world shifts to low carbon. We believe that heat pumps, compared to conventional heating and cooling systems, are more efficient and, when combined with low-carbon electricity sources, will play a critical role in transitioning building heating to low carbon.

Reality Check

Globally, electric heat pumps provide less than 5% of building heating today, yet they could supply more than 90% of space and water heating, with lower CO2 emissions than condensing gas boiler technology3 in electricity grids that have low emission electricity. In Canada, 80% of the energy used in residential housing is being used for space and water heating, and this produces approximately 98%. of residential buildings’ GHG emissions4. In a broader scope, more than half of all buildings in Canada are heated by fossil fuel energy sources5 and only 2.5% of buildings use heat pump technology6.

Into the Future

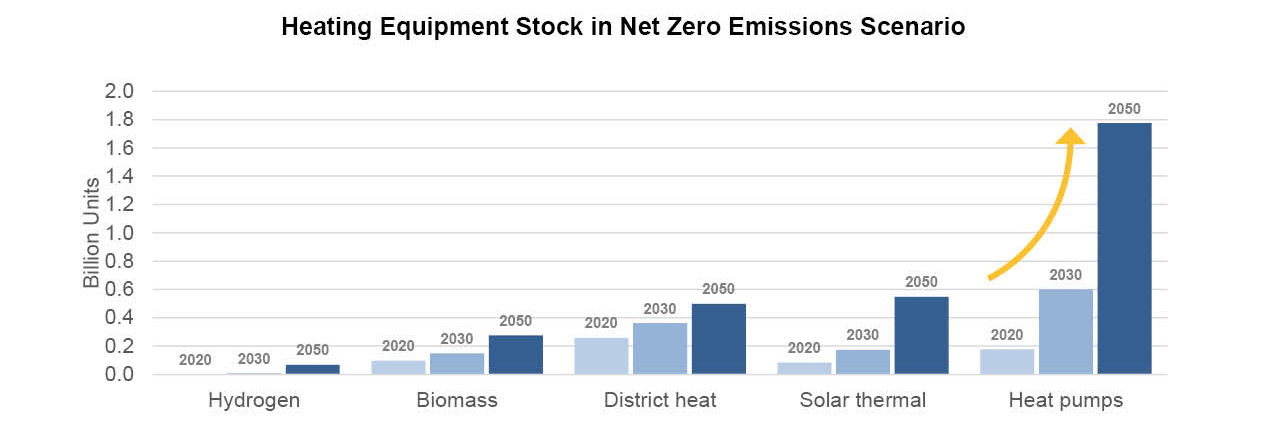

Looking into the future of heat pumps in buildings, the United Nations (UN) developed seventeen Sustainable Development Goals (SDG) which were adopted by all UN member states in 2015. According to recent models, reaching these SDG would require heat pump sales to triple by the year 2030. In addition, heat pumps have to be the dominant technology for heating buildings around the globe. In a net zero scenario, heat pumps will have to replace all natural gas boiler sales that occurred over the last 20 years7, see Figure 1. This prompted us to examine the future opportunities for heat pump technology in buildings.

Data: Net Zero by 2050 (IEA)

Figure 1: Building Heating Equipment Stock, 2020 to 2050

What is a Heat Pump

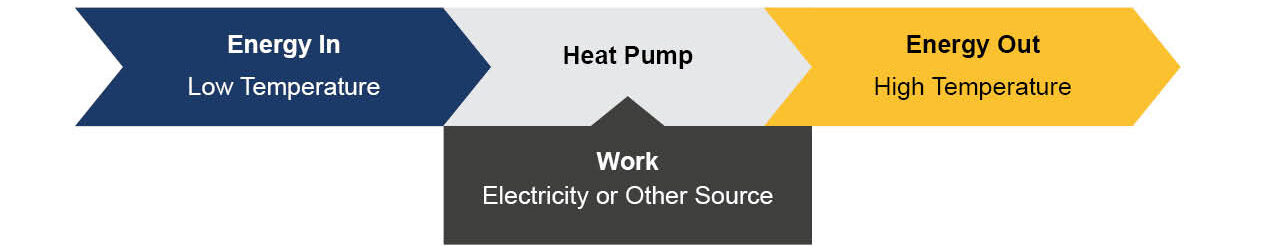

A heat pump is a mechanical machine that utilizes a refrigerant to move heat energy from one place to another. This idea is based on the reversed Carnot cycle where a vapor compression refrigeration cycle uses input work to move heat from a relatively lower temperature energy source to a relatively higher temperature energy sink. The input work can come directly from a fossil fuel-based energy source, such as a natural gas-driven heat pump. Alternatively, the input work can come from an electrically-driven heat pump where the motor is driven by electricity from an electricity grid. This electricity may or may not be carbon free.

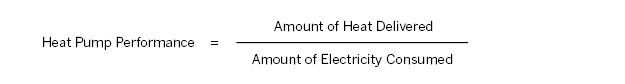

Electric heat pumps can recover low temperature energy from an energy source, elevate its temperature, and deliver it to an energy sink using a relatively small amount of electricity. In fact, the majority of the energy delivered by a heat pump used for heating comes from the low temperature energy source and not from electricity. Building owners or design engineers who evaluate heat pumps for building heating often rely on certain performance criteria to determine the benefit they can get from heat pump heating. Performance is also important when comparing heat pump heating to other heating methods, like using steam or hot water for heating, electric space heating, or direct furnace heating. The typical criteria used to evaluate heat pump efficiency is the Coefficient of Performance (COP) of the heat pump. The COP of a heat pump is the ratio between the heat delivered by the heat pump to the input work provided to the heat pump machine. In the case of electrically-driven heat pump, the input work is in the form of electricity. Therefore, the heat pump COP can be expressed as follows:

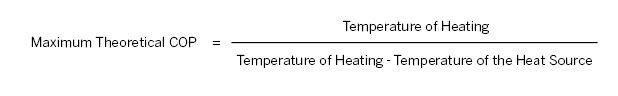

This COP (ratio) is typically greater than 1. This gives the impression that the heat pump has an efficiency higher than 100% which makes heat pump heating look attractive in terms of performance compared to other methods of heating. However, a COP higher than 1 may look significantly better than a natural gas hot water boiler efficiency but it is not necessarily the only indicator of a heat pump performance. Another way we look at a heat pump performance which is less mainstream is through comparing the ratio between the COP of a certain heat pump to the Carnot COP of the same heat pump under the same operating temperatures. The Carnot COP is the theoretical maximum COP according to the laws of thermodynamics. This ratio between a heat pump COP and the Carnot COP is always less than 1. This comparison provides us with a metric for the deviation of the COP of a certain heat pump machine we are evaluating from the theoretical maximum possible COP for this given machine. For reference, the Carnot COP is defined as:

Where all the temperatures noted above are in degrees Kelvin. This evaluation methodology highlights the importance of the design parameters of buildings such as temperature used for heating as well as environmental conditions that affect the heat source temperatures, such as outdoor air temperature or ground temperature. This helps engineers and building owners assess not only the performance of heat pump but also the feasibility of using heat pump heating in a building based on its location and building design parameters.

The good news is heat pump technology has been making consistent progress for the past decade. The performance of the current technology makes the use of heat pumps possible for a wide variety of building heating applications. However, the heating requirements for each building will determine the type of heat pump that is most suitable for the application.

Heat Pump Options

We can group heat pumps into two types based on the source of energy going into the machine: air source or water source. An air-source heat pump (ASHP) relies on air as a source of energy, which can be advantageous for climates that have mild air temperatures; however, in colder climates, the performance of air source heat pumps can deteriorate at lower outdoor air temperatures (typically below -20°C, if the energy source is outdoor air). Air source heat pumps can be installed virtually anywhere if physical space allows for the installation. This can be advantageous if there are no energy sources available to the building. However, the maximum heating capacities of an air source heat pump can be a limiting factor when using such technology for large scale applications, such as campus and district energy heating. Water source heat pumps (WSHP) use water as the energy source; this can be an advantage when abundant energy sources are available to the building, and in cold climates. If the energy source is reliable, water source heat pumps can provide building heating with a relatively smaller equipment footprint compared with air source heat pumps. Water energy sources can originate from ground, in the case of geo-exchange, or waste water heat, as well as process heat recovery in industrial applications or data centers. The caveat is that, sometimes, these energy sources may not be available to the building at all, or only available outside the building or at a distance far from the building, which can make such systems more expensive to construct.

COMING UP:

So far, we have discussed the importance of heat pumps in combating climate change and improving overall building performance and outlined what the technology is and how it works. Click here to read Part 2 of our three-part discussion of heat pump technology examining the cost implications to owners and operators, as well as the considerations, opportunities and risks present for heat pump heating and how to navigate them. For more information about heat pump technology or to speak with one of our energy specialists, contact us at lowcarbon@hhangus.com.

Mike Hasaballa, M.A.Sc, P.Eng.

Mike is a lead engineer and project manager in HH Angus’ Industrial/Energy team. His work focuses on the design of efficient high-performance heating and cooling systems, as well as low carbon energy systems and energy master planning. mike.hassaballa@hhangus.com

Francisco Contreras, M.A.Sc, P.Eng., LEED, AP BD+C, BEMP

Francisco is a manager and energy analyst in HH Angus’ Knowledge Management team. He is very experienced in high performance green building design, building simulations, and energy assessment. francisco.contreras@hhangus.com

1 https://www.worldgbc.org/sites/default/files/UNEP%20188_GABC_en%20%28web%29.pdf

2 https://architecture2030.org/why-the-building-sector/

3 https://www.iea.org/reports/heat-pumps

4 https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.cfm?type=CP§or=res&juris=ca&rn=2&page=0

5 https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.cfm?type=CP§or=res&juris=ca&rn=7&page=0

6 https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.fm?type=CP§or=res&juris=ca&rn=10&page=0

7 https://www.iea.org/reports/heat-pumps