Location: Eastern Canada

Queen’s University

School of Medicine

The Queen’s University School of Medicine is a state-of-the-art multifaceted facility. This project updates, consolidates, expands and relocates the teaching, research, administrative and student facilities, which had previously been scattered across several buildings. The greenfield project was built to ensure sustained teaching and research excellence.

The building is 128,260 ft2 on five levels, plus a mechanical penthouse, and consists of a teaching facility comprising medical teaching spaces, simulation labs and surgical/technical skills labs, autopsy, microbiology and biochemistry labs and support spaces, physiology/pharmacology and support spaces, anatomy and dissection labs, two teaching theatres, medical teaching facilities and study rooms.

The design of this leading-edge facility included a fitout to enable electronic mannequins in the simulation labs, and medical gas installations to permit students to perform simulated procedures. Mechanical specifications encompassed special exhaust equipment in the autopsy rooms to evacuate chemicals used in autopsy processes and body preservation, as well as a fitout for body storage.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: 128,260 ft2 | Status: Completed 2011

LOCATION

Kingston, Ontario

KEY SCOPE ELEMENTS

Mechanical penthouse | Teaching facility comprising medical teaching spaces, distinctive labs and support spaces | Fitout to enable electronic mannequins and medical gas installations

Art Gallery of Ontario

AGO Transformation

HH Angus has been providing consulting engineering services to the Art Gallery of Ontario (AGO) since 1925. Today, the AGO is the 10th largest art gallery in North America.

World-renowned architect Frank O. Gehry designed AGO’s transformation. The project was both an addition (97,763 ft2) and renovation (187,000 ft2), and represented the final phase of a three-phase expansion. Innovative design features were implemented during the phased construction, installation, and commissioning, as well as in the integration of new and existing spaces.

Three main challenges were proposed by the client and the architectural team:

- construction would have to be phased in order to provide ongoing service to galleries

- sophisticated mechanical systems were needed to meet the specific requirements of each gallery, and these would have to be physically remote from the galleries for aesthetics

- integration challenges would have to be overcome in connecting new systems to existing base systems.

The AGO is divided into 70 zones, with each gallery space fitted with dedicated sensors controlling the individual equipment in remote rooms. The mechanical systems were designed to be virtually invisible. The normal paraphernalia of the Heating, Ventilation, and Air Conditioning (HVAC) systems within the gallery viewing areas are not visible to visitors. Reducing fresh air intake during off-peak hours simplified the HVAC system control, and reduced the influence of fluctuations in outside temperature and humidity, providing more stable environmental conditions for the artwork.

The integration of new mechanical systems with existing systems made the already complicated assignment even more complex. The form and arrangement of the new and renovated spaces resulted in an irregularly-connected multi-level project. Interconnected atrium spaces required careful attention to ensure that mechanical services were concealed and that service access routes were maintained. The prediction of temperature- and pressure-induced airflow patterns, and arrangements to segregate returns for balancing return air to individual air handling units, required complex analysis.

In order to avoid the risk of water leakage, which would be a serious issue for the AGO’s collection, all mechanical rooms were located in no-impact areas away from gallery spaces. There is no equipment housed above gallery ceilings for the same reason.

The vertical transportation system includes three passenger elevators, one high capacity freight elevator, two material lifts, and two platform lifts to accommodate persons with physical disabilities. All elevators are of the “traction” type, with special design features to accommodate both large groups and the travel distances required.

We’re very proud to have been involved in the transformation of the AGO – one of Toronto's most important cultural venues.

SERVICES

Mechanical Engineering | Vertical Transportation

PROJECT FEATURES

Size: 486,000 ft2 | Status: Completed 2007

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Phasing to permit ongoing operations | Sophisticated mechanical systems physically remote from galleries | Integration of new and old building systems | 3 passenger elevators, 1 high capacity freight elevator, 2 material lifts and 2 platform lifts | Complex analysis required to study temperature and pressure-induced airflow patterns and arrangements

University of Toronto

Terrence Donnelly Centre for Cellular & Biomolecular Research

University of Toronto institutions are world leaders in the quest to find the link between genes and disease. The Centre for Cellular and Biomolecular Research (CCBR) is an innovative, multidisciplinary facility and the first of its kind in Canada: an advanced research centre capable of competing with the world’s top research and development institutions.

The CCBR was designed as a highly functional, flexible and technically advanced research facility that reflects the University’s status as a world leader in the field of genome research while, at the same time, recognizing the historical importance of its neighbouring buildings.

As a sustainable and green building, the CCBR showcased the use of new and emerging materials as key elements. The double façade curtain wall was one of these unique features. It supports natural ventilation on the south side, circulating air and promoting cooling in hot weather, and acting as a thermal sink in subzero conditions. This stack effect, controlled by variable dampers, considerably reduces the heating and cooling load on the mechanical systems. The curtain wall reduces noise infiltration and decreases heat loss, with the outer leaf of the double façade functioning as a shield to buffer the interior from the urban wind tunnel of the adjacent College Street, a major city thoroughfare.

Energy conserving measures were applied to the laboratory systems to minimize energy use while meeting stringent laboratory standards. Separate plumbing systems were developed to avoid contamination of the environment by laboratory waste and to collect rainwater for distribution to the Winter Garden.

HH Angus met the challenges of this unique facility by designing and engineering systems that will allow this building to stand the test of time as an example of innovative sustainable design.

SERVICES

Mechanical Engineering | Electrical Engineering | CCTV | Security and Communications | Preliminary Vertical Transportation Review

PROJECT FEATURES

Size: 221,000 ft2 | Status: Completed 2006

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Double façade curtain wall was introduced to reduce noise infiltration & decrease heat loss | Energy conservation measures | Full Building Automation System designed

Integrating new and old

The CCBR is a 13-storey glass tower surrounded by historical buildings. With a gross floor area of 221,010 ft2, it is an outstanding example of sustainable design, comprising a range of variable space requirements: highly controlled laboratory floors are located beside naturally ventilated public spaces like the Winter Garden.

Improving efficiency with BAS

A full building automation system was designed for this building.

Siemens Canada

Algonquin College Trigeneration Plant

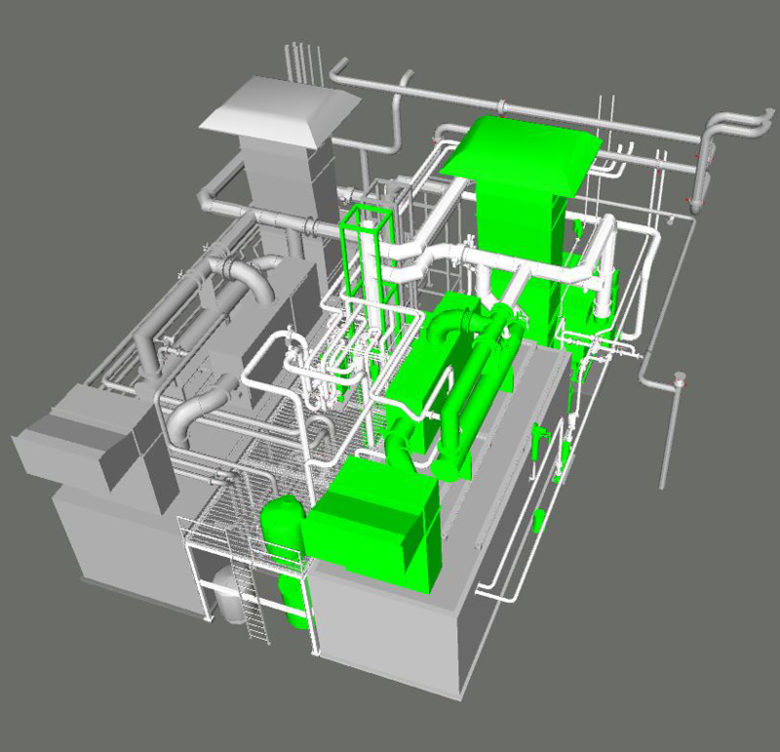

HH Angus was retained to design a trigeneration plant for Ottawa’s Algonquin College. Our scope included review of Siemens’ PSUI application to IESO, and assisting with their application. Because the existing central utility plant (CUP) was not large enough to accommodate new plant systems, our team developed a pre-engineered building to be built adjacent to the existing CUP.

As Prime Consultant, HH Angus retained Milman and Associates to undertake the required structural engineering, including a roof design to accommodate the cooling towers, rad cooler and transformer. An additional mezzanine was added to house auxiliary equipment.

In order to maximize the usable heat during summer months, a 350 ton absorption chiller, using double effect flue gas and hot water, was detailed. The 2 MW reciprocating trigeneration plant features selective catalytic reduction units and a heat recovery boiler.

Some project challenges included:

- Integrating and commissioning a trigeneration system into an operating facility

- Noise constraints due to proximity of CUP to College operations

- Space constraints due to pre-engineered building

- Footprint was maxed out based on site restrictions; HH Angus had to take into account future co-gen, chiller and ancillaries

- Ongoing upgrades in CUP heating and cooling, which HH Angus coordinated with another consultant

- Operating flexibility required for both parallel and island operation

- Solutions included: designed mezzanines in the existing CUP to house equipment and accommodate new, pre-engineered building for the second cogen and chiller; and rigorous scheduling coordination with Utility and College operations staff

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Review of PSUI application to IESO | 350-ton absorption chiller | 2 MW reciprocating trigen plant with selective catalytic reduction units & heat recovery boiler

Minimizing Disruption

All new equipment was connected to existing systems, with electrical connections restricted to well-planned shutdowns, resulting in minimal disruption to the ongoing operations of the campus.

SickKids

Peter Gilgan Centre for Research & Learning, ICAT

Creative solutions were required to accommodate the extremely intense and sophisticated computer systems within the architectural constraints of this building.

Angus Connect provided a Canadian first — the design and implementation of an HPC-High Performance data centre in a healthcare research facility.

Our recommended technical solution involved an overhead communications wiring system design, using multiple cable trays with an integral cable access management system. This innovative system design solution resulted in considerable space savings over a conventional system. A conventional raised floor communications cabling system was not an option due to space restrictions.

This Data Centre, which supports data cabinets with high performance servers that use 60 KW load, required very large and fully redundant Uninterruptible Power Supplies (UPS) and emergency generator systems to support the critical loads.

The facility has been certified LEED® Gold. The shell and core design were already well along when the Hospital’s High Performance computing group announced their intention to locate all of their high performance computing equipment into the new Data Centre.

SERVICES

Mechanical Engineering | Electrical Engineering | IT Communications Design | Lightining Design

PROJECT FEATURES

Size: 740,000 ft2 | Status: Completed 2013

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Introduced innovative system solutions for urban-space saving, along with sophisticated computer systems | LEED Gold Certified