Location: Eastern Canada

Airport Development Corporation

Pearson International Airport - Terminal 3

When Terminal 3 opened in 1991, the 2.8 million ft2 complex was an innovative mixed-use facility consisting of a 24-gate airport terminal, a 500-room hotel, a 3,200-car parking garage and up to 450,000 ft2 of future office space.

The project design combined the priorities of passenger comfort with technical requirements, while emphasizing fiscal responsibility. The terminal has undergone several major renovations since then, resulting in significant expansions to the Central Processor and Pier C.

Vertical Transportation (VT)

The HH Angus VT group was involved from the Concept Design through to inspections, with full design responsibility for the transportation systems, which, at that time, included more than 90 elevating devices, (elevators, escalators and moving walkways).

Our design team’s responsibilities involved managing specification and bid assessment, up to and including final acceptance reviews. The development combined the latest technology with private enterprise economics, which, as it related to VT, translated into excellent standards of service. Later expansion of Pier C included the addition of five elevators, four escalators and six moving walks.

Expansions to the Central Processor included the addition of four elevators and four escalators in the East Processor Expansion, and three elevators, three escalators and two moving walks in the West Processor Expansion.

Within the East Processor expansion, a pedestrian tunnel to the parking garage was introduced to reduce curb traffic between the Terminal Building and parking garage. As a result of this tunnel connection, the three primary elevators on the Terminal side were designed to accommodate the anticipated number of peak hour passengers and associated baggage and carts.

Lighting

Angus Lighting worked in concert with the architectural team to develop lighting design concepts for this prestigious airport. The architectural design called for lighting that would bring excitement to each space, complement the architects’ ambitions and be economically viable.

Special attention was given to innovative lighting techniques with the various lamp sources needed to make the Grand Hall one of the focal points of the terminal.

The resulting design incorporated space, light, brightness, colour, scale and form, while consuming a mere 1.2 watts per square foot.

SERVICES

Vertical Transportation | Lighting Design

PROJECT FEATURES

Status: Stage 1 - 2004, Stage 2 -2007

LOCATION

Mississauga, Ontario

KEY SCOPE ELEMENTS

Design combined passenger comfort with technical requirements while emphasizing fiscal responsibility | Provided support from concept design to inspection with full design responsibility for 90+ elevating devices | Introduced innovative lighting techniques with various lamp sources

Award-winning Lighting Design

Our lighting design for this project was honoured with the prestigious Edwin F. Guth International Award of Excellence.

The Granite Club

Aquatics Complex

The fourth Granite Club opened in 1972 on a beautiful twenty-two acre site on Bayview Avenue, bordering Toronto’s Don Valley. HH Angus was an integral part of the design and construction team for this premier facility, which provides members with one of the most complete and well-equipped athletic facilities in Canada.

HH Angus is privileged to enjoy a 40-plus-year relationship with the Granite Club and has been involved with many upgrades to the 80,000 ft2 structure since it opened.

The mechanical, electrical and lighting design for the Aquatic Complex renovation included features such as a competition-scale swimming pool, training pool, whirlpool, and children’s pool with water features. Design of the addition also addressed the retractable roof and retractable perimeter walls.

The retractable roof posed a challenge for our lighting design team, who had to identify the location of the fixed structural members and incorporate the appropriate lighting design to address the sloped roof. The solution was the selection of luminaires and supporting details on the fixed structural members of the roof construction, accommodating the retractable roof elements.

HH Angus has also designed upgrades to seven squash courts, four badminton courts, eight curling rinks and separate skating rink, bowling alley, outdoor lawn bowling area, six tennis courts, and a fitness centre.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 80,000 ft2 | Status: Completed 2008

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Electrical, mechanical, & lighting design for expansion including competition-scale swimming pool, training pool, whirlpool, and children's pool | Retractable roof and retractable perimeter walls

Upgrading sports and fitness facilities

HH Angus has also designed upgrades to seven squash courts, four badminton courts, eight curling rinks and separate skating rink, bowling alley, outdoor lawn bowling area, six tennis courts, and a fitness centre.

— Photos Courtesy Granite Club

University of Guelph

New Science Complex

The University of Guelph undertook an expansion of its Faculty of Science facilities. The complex was constructed in two phases, with the first being a 4-storey, 360,000 ft2 building to house the Departments of Chemistry, Botany, Zoology and Microbiology.

Phase 1 was the 160,000 ft2 New Science Complex. The ground floor is a research module consisting of a large nuclear magnetic resonance suite, electron microscope rooms, and a mass spectrometry facility. An extensive chemical storage area was also located on ground level, and a greenhouse facility was built on the roof.

Phase 2 featured additional graduate research ‘wet’ labs and teaching laboratories in its 200,000 ft2 footprint. An atrium space provided amenities such as a student lounge area and food services facility. Office and support areas were also included.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: 360,000 ft2 | Status: Completed Phase I 2004, Phase II 2006

LOCATION

Guelph, Ontario

KEY SCOPE ELEMENTS

3 floors of teaching labs, 3 floors of graduate research wet labs | Extensive chemical storage area on ground level | Greenhouse facility on the roof | Office and support areas

Comprehensive Education Centre

The building formerly known as the Sciences, Advanced Learning and Training Centre (SALT) is now called the New Science Complex.

Engineering multiple laboratory types

The Phase 1 facility features three floors of teaching labs for the Chemistry Department and three floors of graduate research ‘wet’ labs. The ground floor is a research module consisting of a large nuclear magnetic resonance suite, electron microscope rooms and a Mass Spectrometry facility. An extensive chemical storage area is also located on the ground level. A greenhouse facility is located on the roof of this part of the building

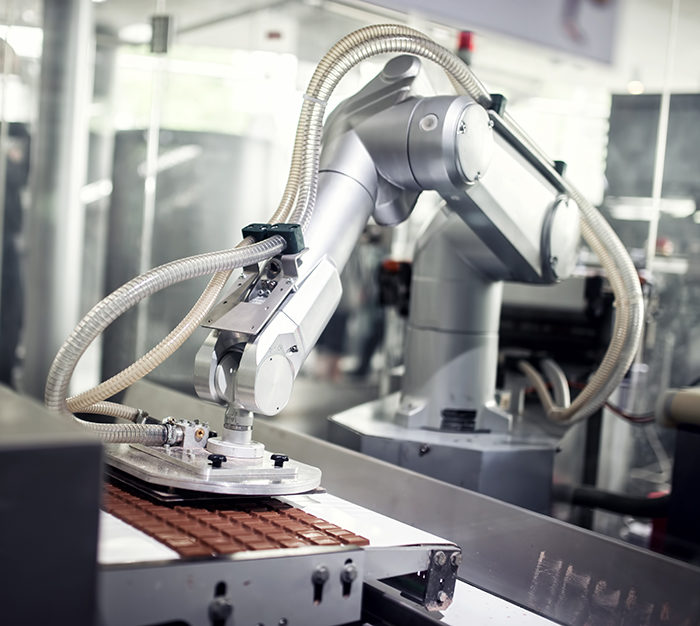

Cadbury Canada

Weston Foods Gladstone Avenue Plant

The Weston Foods plant has undergone many mechanical and electrical renovations and upgrades with HH Angus and Associates serving as prime consultant.

Producing chocolate and confectioneries has many challenges. They require viscous fluid pumping and precise control of temperature and humidity levels in order to produce quality chocolate. These engineering challenges were compounded by the plant’s urban location in a residential area, which meant that all amendments to the exterior of the plant had to be compatible with the neighbourhood.

HH Angus was engaged to review the plant, which had been operating for 20 years. This was done to establish current production requirements and to assist in projecting requirements for future growth.

HH Angus’ work at the plant included:

- Development and construction of a new central plant to provide steam, water, compressed air, refrigeration, and HVAC services for confectionery production. The plant featured a 2000 ton ammonia-to-water process chilling and air conditioning plant to condition 300,000 cubic feet per minute for air conditioning and ventilation of production areas, and for remediation of noise and odours within the plant. Renovation of the office and manufacturing facilities involved relocation of 13 production lines to preferred locations and reworking the electrical power distribution system. During the time the renovation was in progress, production was sequentially phased in selected areas, and high levels of quality production were achieved with no impact on product quality.

Processes and spaces involved in the renovations and upgrades included:

- Pumping of multiple grades of chocolate with double-walled hot water heated piping for chocolate transportation

- Pumping of chocolate liquor, fats and food oils, glucose, sugars, caramel, nougat; transport piping and storage tanks

- Bulk milk delivery with tanker cleaning facilities

- Freezer storage warehouse space for ice cream

- Cool storage for chocolates

- Cold storage for production ingredients

- Process water recovery system for process chilled, cold and hot water, which reduced plant water consumption with significant savings

- 50,000 US gallons per day process effluent discharge control system to reduce biochemical oxygen demand and suspend solid level of process effluent to meet stringent City of Toronto requirements

- Special humidity control (30% RH or lower) for hydroscopic confectionery process rooms

- Air systems to handle process-generated dust and vapour extraction for peanuts, raisins, alcohol solvent-based candy coatings, and sugar conveying

- Review of process cooker and votator (scraped surface heat exchanger) of foreign manufacture with respect to ASME pressure vessel code compliance

- Upgrading of 2200 ton ammonia refrigeration condensing system to all evaporative condensing equipment, with 28 stages of condensing. Design of microprocessor-based control system for: optimized selection of equipment to maintain condensing pressure; automatic selection of quietest equipment for night-time operation; automatic selection/deletion of condensing stages for summer or winter operation.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2006

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Development and construction of new central plant facility | Steam, compressed air, refrigeration and HVAC services | Renovation of office and manufacturing facilities

Working with Affiliates

In addition to the work in the chocolate and confectionery plant, HH Angus and Associates has been involved with Weston Group food plants at:

- Weston Bakeries

- Neilson Dairies

- Loblaw Supermarkets

Holland Bloorview

Kids Rehabilitation Hospital

“Bloorview sets a new benchmark for the shape patient- and family-centred health care should take in the future.”

— Beth Kapusta, Azure Magazine

Holland Bloorview Kids’ Rehabilitation Hospital is a 5-storey 343,000 ft2 rehabilitation inpatient/outpatient facility that replaced two existing facilities. It includes a 75-bed inpatient unit, specialized clinics, school, lap pool, therapeutic pool, cafeteria and central kitchen, technical laboratories and administration offices.

The main design objective was to create an environment that was inviting, friendly and safe. In patient rooms, indirect lighting and downlights create a cozy atmosphere. LED night lights and wall-mounted non-commercial, glare-free bed lights mimic sconces while enhancing comfort and safety. Daylighting throughout the building significantly reduces environmental impacts for this 24/7 healthcare facility.

In the lobby, a colour window displays LED scenes controlled by motion sensors that are triggered when children walk by, creating a fun and interactive environment. The design is sense-oriented with colour distractions, and incorporates low-glare and natural daylighting.

The Snoezelen Room, the first of its kind in North America, uses light as therapy, incorporating multi-level, colour-changing, indirect and twinkling lighting. Its focal point is a therapeutic pool using an indirect, direct and snoezelen lighting for children’s therapy. The pool’s higher temperature required design considerations to control the higher humidity and space temperatures.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | IT & Communication Design

PROJECT FEATURES

Size: 343,000 ft2 | Status: Completed 2006

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

5-storey facility | Innovative lighting design incorporated in Snoezelen Room - first of its kind in North America | Lobby Colour Window displays motion-controlled LED scenes

Inviting the neighbours in

The recreation pool was designed as a community facility. The lighting features wall-mounted and suspended indirect lighting. The lap pool was located on the exterior of the building with exterior glazing. This posed a challenge in keeping the windows clear of condensation with the high humidity levels from the pool. Air curtains at the windows were incorporated to help eliminate the condensation build-up.

Optimizing design for a sustainable result

Extensive input from the entire design team resulted in an environmentally-sensitive design. A series of workshops were held during Design Development to optimize all aspects of the building, and to maximize use of sustainable materials.