Location: International

Tecnológico de Monterrey, Mexico

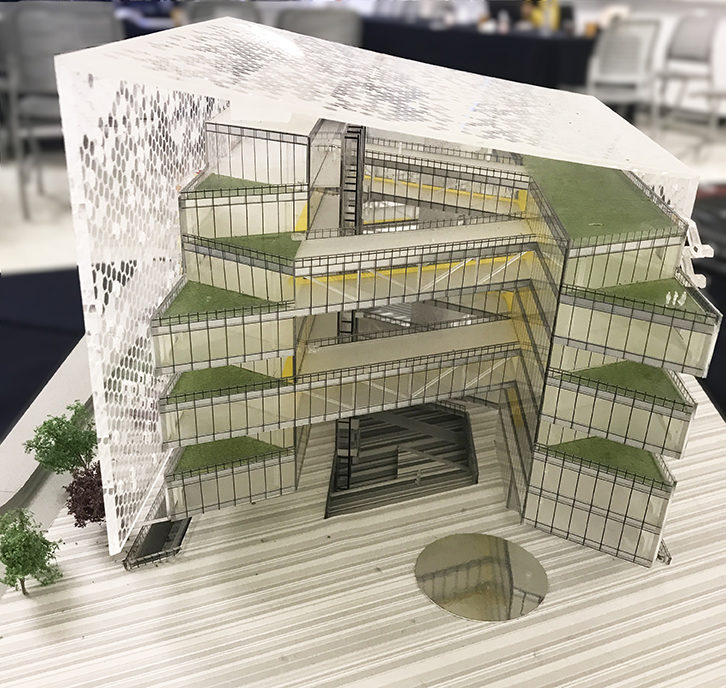

TecNano Academic BuildingTecNano is a proposed new academic building that combines a variety of lab spaces containing co-working environments. The intent is to support a highly interactive and collaborative research experience within the biotech lab building.

Tecnológico de Monterrey is a multi-campus private university in Monterrey, Mexico. The university has grown to 36 campuses throughout Mexico, with the Monterrey campus serving as its flagship institution.

HH Angus was engaged to provide ICAT (information, communications and automation technology) design services for a proposed new building, the TecNano Academic Building. The IT design scope included a main data centre with a subsidiary data centre dedicated to Multiomics. The IT design was based on a stacked central riser, with main and redundant facility entrances from the street and from the rear, connecting to the campus backbone. Wi-Fi would be available throughout the building, with lab benches and overhead carriers providing wired data connections.

The building design required an innovative solution to locating the IT backbone. We designed a riser in the exterior channel up the north side of the building to facilitate the open-air atrium as well as a stacked riser.

The security scope included access control, CCTV, duress alarms, and a central guard station with CCTV monitoring. The facility was designed with medium to high security measures, and featured dual factor credentials for specific lab entrances. There was one clean room with anteroom, and several isolation and pressurized anteroom labs, all requiring interlock and high-speed overhead doors.

Physical security also presented challenges. Intended to be welcoming, safe and secure, the facility was designed to be open to the campus on the North side and to act as a gateway to the campus from the street on the South side. We provided glass high-speed entrance portals for entrance circulation. The solution also had to function well in Monterrey’s extreme environment. Working with the architect, we provided a safe, secure, and high-speed portal that would be protected from the elements by the atrium ceiling high overhead.

The AV systems included a public auditorium with distance learning and lecture capture, video conferencing-enabled faculty boardroom, as well as AV-enabled student meeting, study, and huddle spaces. Digital signage in IP-65 enclosures provided wayfinding at the entrance for the facility and campus

The TecNano Academic Building laboratory types included:

Nanophotonics

Molecular Simulation

Metallomics

Advanced Optical Microscopy

Nanostructure Synthesis

Micro and Nanofabrication

Multiscale Manufacturing

Materials Characterization

Synthetic Biology

High Throughput Bioprocesses

Microrobotics

Tissue Engineering and Bioprinting.

SERVICES

ICAT Consultant - Security, Audiovisual and Communication Design

PROJECT FEATURES

Size: 25,500 m2 | Status: Design Completion 2018

LOCATION

Monterrey, Mexico

KEY SCOPE ELEMENTS

Biotech laboratory building, including clean room and nanotechnology labs | International collaboration – Client in Mexico, Architect in United States, ICAT and Vertical Transportation consultants in Canada

Innovative solutions

An interesting challenge affected the communications design, specifically the outside plant design. When the local municipality rejected street closures to install a communications duct bank for carrier entrance cabling, we surveyed the site, the facilities, and routing together with TecNanao IT, and designed a campus-internal route to meet the carriers’ entrance to the East. While it is a much longer route, it is also simpler to permit, as it was not located within the municipal right-of-way.

Image credits: FGP Atelier

Bermuda International Airport

Redevelopment and New Terminal

The L.F. Wade International airport is the world’s gateway to Bermuda, and the redevelopment of its existing Passenger Terminal Building (PTB) was a high priority for the small island country. Because the current terminal is prone to flooding, it is susceptible to damage from major Atlantic storms, which could seriously impact Bermuda’s vital tourism industry.

The PTB redevelopment was undertaken as a P3 project. HH Angus provided mechanical engineering and vertical transportation design for all systems serving the airside and the PTB, working with a local affiliate to deliver contract administration services during construction.

The vertical transportation scope for the project included five new machine-room-less (MRL) traction passenger elevators and four escalators.

Some of the interesting challenges of the project included its profile as an international project on an island; adapting to local authorities having jurisdiction; resistance to hurricanes; flood mitigation; and the island’s water strategy–Bermuda's building code requires that all rainwater be captured and re-used, and the new PTB represents the largest roof area in the country. Also, salt-laden air and accelerated corrosion require the use of non-traditional materials as compared, for example, to similar buildings in Canada.

Among the features of the engineering design, the high water table easily allowed for geo-thermal heat rejection for the cooling plant.

SERVICES

Mechanical Engineering | Vertical Transportation

PROJECT FEATURES

Size: 2,886,902 ft2 (26,820 m2) | Status: Completion 2020

LOCATION

St. George's, Bermuda

KEY SCOPE ELEMENTS

Five new machine-room-less (MRL) traction passenger elevators and four escalators | Innovative mechanical design | Geothermal heat rejection for cooling plant | Mandated rainwater reuse for largest roof area in the country

Innovation and Excellence Award

The Bermuda airport project was awarded a 2021 Gold Award for Innovation and Excellence in P3s, from the Canadian Council for Public-Private Partnerships. It is only the second international project recognized by the

CCPPP in its history.

— Renderings courtesy of Scott Associates Architects Inc.

Bangalore (Kempegowda)

International Airport

The Bangalore (Kempegowda) International Airport airport expansion will increase the airport’s capacity to at least 65 million passengers per annum. Phase 1A of the new Terminal currently includes an estimated 46 elevators, 29 escalators, and 17 moving walks.

In addition to the new Terminal, a multi-level car park is being constructed to accommodate an estimated 2438 passenger vehicles after Phase 2. In addition to the vehicle stalls, there is capacity for an estimated 450 taxi’s after Phase 2. A Metro connection to the Terminal is also planned following Phase 2 expansion, for which elevating provisions are currently being made.

HH Angus’ client is Skidmore, Owings & Merrill LLP (SOM) from New York, with whom we worked previously on a joint-venture architectural team with Adamson Associates and Moshe Safdie on Terminal 1 at Toronto Pearson International Airport.

SERVICES

Vertical Transportation

PROJECT FEATURES

Status: Ongoing

LOCATION

Bangalore, India

KEY SCOPE ELEMENTS

46 elevators | 29 escalators | 17 moving walks for new Terminal Building and multi-level car parkade for 1724 vehicles, with Phase 2 planned expansion to 2438 passenger vehicles

MAN Diesel

Bonaire, 14 MWe Power Station

The island of Bonaire (formerly the Netherlands Antilles), has been a special municipality of the Netherlands since 2010. It lies in the Leeward Antilles chain of Caribbean islands, with an area of 288 square kilometers (111 sq.mi.)

With the commissioning of its sophisticated new sustainable wind-diesel hybrid power plant, Bonaire became the first Caribbean island capable of 100% renewable energy. This project’s aim was to transform today’s largely fossil fuel-based energy supply infrastructure in Bonaire into one based on the application of 100% sustainable energy sources within five years (bio diesel extracted from algae).

The Bonaire project featured a 14 MWe turnkey power station with site work, roads and electrical connections. HH Angus was responsible for all mechanical, electrical, civil structural engineering, including various piping systems (heavy fuel oil, light fuel oil, lubricating oil, compressed air, etc), high and low voltage distribution, and PLC control systems. All mechanical detailing was completed with 3D CAD software, with related materials captured in Excel for the bill of material procurement.

Our design scope covered a capacity increase to 20 MW (designed for future use) and was based initially on Heavy Fuel Oil (HFO) as the principal fuel, and light fuel oil (LFO) as an alternative. The plant was designed with the capability to be converted to operate on biofuel in future. Also included in the project was an extensive tank farm with storage of HFO, LFO and lubricating oil.

The plant consists of 5 X2.85 MWe MAN Diesel generating sets at 11kV, and was designed as a base load plant with parallel displacement production from a windfarm generating system. Each genset is selectable to dual busbar systems that each step up to 30kV for island distribution.

This is the only power plant on the island. The diesels supply voltage regulation, as well as VARs and power production to supplement the island’s needs when wind production has been harvested to maximum benefit.

Special care had to be taken to integrate the control systems of the wind turbines and the diesel engines, as the grid performance has to be maintained through fluctuations of the wind resource. The diesel engines have to respond to the changes in output from the wind turbines in order to maintain electrical grid balance.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2010

LOCATION

Leeward Antilles, The Caribbean Islands

KEY SCOPE ELEMENTS

Wind-diesel hybrid power plant | 100% renewable energy | 14 MWe turnkey power station | Piping system, civil structure, high and low voltage distribution and PLC control systems | Capacity increase to 20MW | Heavy fuel oil as principal fuel & light fuel oil as alternative | Extensive tank farm with storage of HFO, LFO and lubricating oil

MAN Diesel

Ariguanabo Cuba, ~23 MWe Power Generation Plant

In 2006, the government of Cuba began an ambitious $2 billion program to modernize its decaying Soviet-era energy infrastructure.

For this ~23 MWe turnkey power station in the town of Ariguanabo, approximately thirty miles from Havana, HH Angus was engaged to provide all mechanical and electrical detailed design, including various piping systems (heavy fuel oil, light fuel oil, lubricating oil, compressed air, steam tracing, etc.), as well as high and low voltage distribution.

The power plant consists of twenty ~1.15 MWe MAN diesel generating sets and was designed as a continuously operating plant.

Generation is at 13.8kV onto a double-ended station (10 generators/bus), stepping up to 34.5kV for distribution across the entire island of Cuba. The plant was designed to operate as a base load plant. The site included extensive tank farm storage of heavy fuel oil, light fuel oil and lubricating oil. Steam tracing was provided on HFO systems. The main fuel is heavy fuel oil, with light oil as the backup.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2009

LOCATION

Ariguanabo, Cuba

KEY SCOPE ELEMENTS

~23 MW Power Station (20 X 1.15 diesel generating sets) | Continuous operation / functions as a base load plant | High and low voltage distribution