Location: Western Canada

Northern Health Authority

Dawson Creek & District Hospital Replacement Project Operational Readiness

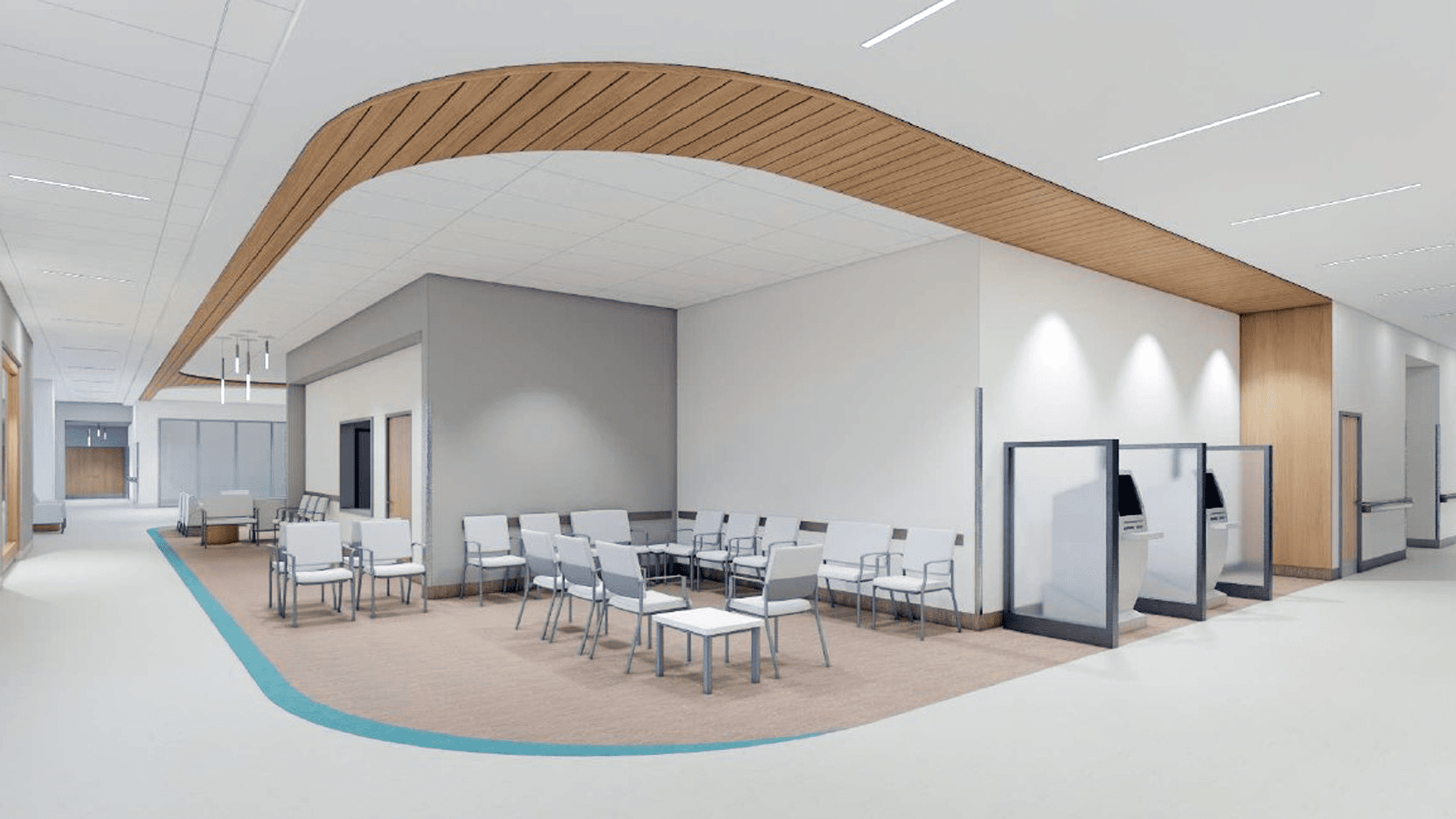

BC's Northern Health Authority is building a state-of-the-art hospital as a model of excellence in healthcare. The new Dawson Creek & District Hospital is being built in Treaty 8 territory, the ancestral home of the Beaver, Cree, Saulteau, Sicannie (Sikanni), and Slavey, and will serve numerous diverse communities.

The Dawson Creek and District Hospital (DCDH) is a 263,000 ft2 facility on a greenfield site, replacing the existing hospital. This three-story hospital will house an emergency department with 15 treatment spaces and 70 inpatient beds offering medical, surgical, maternity, high acuity, and mental health services. Additionally, it will feature 2 operating rooms, a procedure room, diagnostic imaging, a chemotherapy area, a perinatal unit comprising labor, delivery, recovery, and postpartum rooms, a nursery, mental health department, academic and teaching space, along with pharmacy services. The facility is being designed to meet LEED Gold certification standards.

As part of a comprehensive operational readiness engagement, Angus Connect is supporting DCDH through a structured, multi-phase approach to ensure a smooth transition to operational status. Our scope of work was divided into three main phases:

- Phase 1: Project initiation and assessment

- Phase 2: Development and implementation

- Phase 3: Transition plan, move, and learn (targeted: Summer 2026 – Summer 2027)

Each phase addresses specific readiness needs, while ensuring continuous alignment with the hospital’s operational and clinical objectives. In the first phase, Angus Connect worked closely with DCDH leadership and operational teams to establish a solid foundation for the hospital’s operational readiness. This involved educating key stakeholders about the process and their roles, facilitating workshops to develop a master schedule that aligned project milestones with hospital priorities, and assessing the organization’s preparedness for operational readiness planning. A comprehensive Operational Readiness Project Charter was created, outlining governance structures, planning assumptions, risk management strategies, and stakeholder engagement approaches.

The tailored operational readiness framework was a core deliverable, providing DCDH with tools, templates, and checklists to guide clinical and non-clinical program readiness. This framework addressed key elements such as change management, workflow redesign, human resource planning, equipment strategies, and emergency measures planning. A Gap Analysis was conducted to assess current clinical offerings and identify areas that required specialized resourcing for the transition. The findings were used to develop Change Maps that identified areas where large changes were going to take place. Examples of these are technology and equipment changes that could transition a hospital from manual paper-based workflows to integrated digital systems.

Our team conducted patient journey mapping for clinical departments and materials mapping for non-clinical operations for a clear understanding of new logistics and process flows. Training requirements identified fed into the development of the Orientation, Training, and Education Tracker, a tool designed to identify all mandatory training and orientations for the hospital.

To align each department’s readiness with the broader operational goals, we facilitated a corporate opening day view session with program leaders to define future-state requirements, develop and confirm service delivery models, and identify inter-departmental dependencies. The outcomes provided a foundational understanding for all clinical and non-clinical departments on what First Patient Day would look like.

Phase 2 focuses on the development and implementation of detailed operational readiness work plans for all programs, services, and subcomponents. These plans address the gaps between the current and future operational states, breaking down desired plans into necessary tasks. The phase involves workflow and process redesign, clinical model of care planning, equipment planning, risk management, emergency measures, and internal and external communication strategies.

Angus Connect also provides strategic guidance on ICAT and equipment planning, supports early visioning for Departmental Opening Day Views, and facilitates a risk workshop to identify challenges and mitigation strategies. Phase 3 will include the development of Transition Plans for activities leading up to Opening Day, ensuring the hospital is fully operational and supported until after three months post-occupancy.

Our team’s operational readiness support sets the stage for successful implementation of all phases of the project, providing DCDH with a clear, structured path to achieving full operational capacity in the new hospital.

SERVICES

Operational Readiness Consultant

PROJECT FEATURES

263,000 ft2 three-story facility | Serving Treaty 8 First Nations, Métis, and Peace Region communities | Targeting LEED Gold certification | Completion 2027

LOCATION

Dawson Creek, Alberta

KEY SCOPE ELEMENTS

Comprehensive Operational Readiness framework | Gap analysis | Change maps | Patient journey mapping | Opening Day view session | Development and implementation of operational readiness work plans | ICAT consulting | Transition plans

Images Courtesy of Graham and Northern Health.

Interior Health

BC Cancer Centre

The new BC Cancer Centre is described as the single largest capital investment into the expansion of cancer care in the Kamloops region.

Interior Health, in partnership with BC Cancer, is building a new cancer centre at the Westlands site of the Royal Inland Hospital in Kamloops, BC. The new facility includes design and construction of a 5-storey outpatient radiation oncology clinic. Featuring three linear accelerators for radiation therapy, a CT simulator, a diagnostic MRI, ambulatory care space, a 470-stall parkade and an interfaith sacred space for patients and families, the new Cancer Centre will respond to increased demand for cancer services on the main campus, and facilitate 16,500 treatments annually while significantly reducing long-distance travel for many patients.

HH Angus is providing mechanical and electrical engineering, ICAT design and vertical transportation consulting services for this project which is led by EllisDon Corporation.

The Kamloops Cancer Centre is scheduled for completion in 2028.

Image Credit - Interior Health

SERVICES

Mechanical Engineering | Electrical Engineering | ICAT/IMIT Design | Vertical Transportation Consulting

PROJECT FEATURES

5-storey outpatient radiation oncology clinic | Design-Build delivery model | 470-stall parkade | Interfaith sacred space | Completion 2028

LOCATION

Kamloops, British Columbia

TELUS

Len Werry Building Turbine Replacement

The TELUS Len Werry Building in downtown Calgary houses offices, computer facilities, toll switch equipment, and local switching equipment for a major toll complex.

The project involves the replacement of the building's existing turbines with new reciprocating diesel generators and redundant synchronization switchboards in a new penthouse on top of the building.

HH Angus is providing electrical engineering services to support upgrades to the electrical distribution system related to the installation of the new diesel generators.

SERVICES

Electrical Engineering

PROJECT FEATURES

Infrastructure replacement in occupied commercial tower | Status: Ongoing

LOCATION

Calgary, Alberta

KEY SCOPE ELEMENTS

Upgrades to electrical distribution system

The Co-operators Calgary

Tenant Fitout

This project focused on a tenant renovation of two floors in The Co-operators' newly-acquired downtown Calgary office space, and comprised 40,000 square feet. The project has been certified WELL Gold.

Our approach included early coordination with the landlord to ensure handover conditions suited the client’s requirements, as well as close coordination with the construction manager in creating a pre-order due to a condensed construction schedule.

The construction schedule was a key challenge of the project along with the timing of tender. The completion date was an unmovable milestone as the client’s lease was expiring at their other location. At time of tender, product and material availability were fluctuating, which created uncertainty around delivery. To meet the deadline, our team was tasked to do everything possible to ensure the success of the project and keep the schedule on track.

To help ensure timely delivery, our team incorporated a pre-order package for the construction manager to tender, which allowed products to be reviewed and released ahead of the official tender. This effort was successful and was completed according to plan; however, some delivery delays were unavoidable, due to market conditions. To mitigate the impact, we were then tasked with contacting industry partners to help expedite deliveries. In addition, alternative temporary designs were implemented to ensure the move-in date could be met by planning the switchover date once the outstanding equipment arrived.

The Calgary office marks our fifth tenant improvement project for The Co-operators, following similar fitouts for their locations in Guelph ON and Regina SK, as well as pilot projects in Montreal QC and Burlington ON.

New Lutron lighting control design

New UPS N+1 Design and new LED Lighting Design

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | Communications & Security Design

PROJECT FEATURES

Size: 40,000 ft2 over two floors | Status: Completed 2023

LOCATION

Calgary, Alberta

KEY SCOPE ELEMENTS

Feasibility Study | Tenant renovation | Condensed construction schedule | WELL Gold certified

Fraser Health

New Surrey Hospital and BC Cancer Centre

Surrey BC is a fast-growing community in need of additional healthcare resources. The New Surrey Hospital and BC Cancer Centre will provide 168 hospital beds and 55 Emergency Department treatment spaces in a state-of-the-art facility to improve health services in the region.

The $2.88B hospital project reached its one-year construction milestone in August 2024 and is anticipated to be completed in 2029 and open to the public in 2030. Additional features of the fully-electric facility include a surgical/perioperative suite with five ORs, four procedure rooms and virtual care options in all clinical service areas to increase capacity and expand care. The new BC Cancer Centre is expected to provide approximately 105,000 ambulatory oncology care visits, 50,000 radiation therapy visits and 22,000 chemotherapy visits each year. The facility is being built under a Design-Build Agreement with EllisDon Design Build Inc.

Leading BC's first generation of smart hospitals, the new Surrey hospital will embed data insights and new technologies into both the design of the facility and delivery of clinical care. The Angus Connect team is providing a full spectrum of ICAT/IMIT design and AGV consulting, and HH Angus’ Vertical Transportation team is designing the elevator systems.

Images courtesy of Fraser Health and EllisDon Design Build – conceptual renderings, subject to change

SERVICES

ICAT/IMIT Design | AGV Consulting | Vertical Transportation Consulting

PROJECT FEATURES

Smart hospital | Fully electric facility | Design Build | 168 hospital beds, and 55 ER beds | Perioperative suite with 5 ORs and 4 procedure rooms | Status: Completion anticipated for 2029

LOCATION

Surrey BC

KEY SCOPE ELEMENTS

Information, communications and automation technology | Automated guided vehicle design consulting | elevator design consulting

New BC Cancer Centre

The facility will provide ~105,000 ambulatory oncology care visits, 50,000 radiation therapy visits and 22,000 chemotherapy visits annually.

Smart hospitals

The NSHBCCC is one of BC's new generation of smart hospitals.