Location: Western Canada

Gas Drive

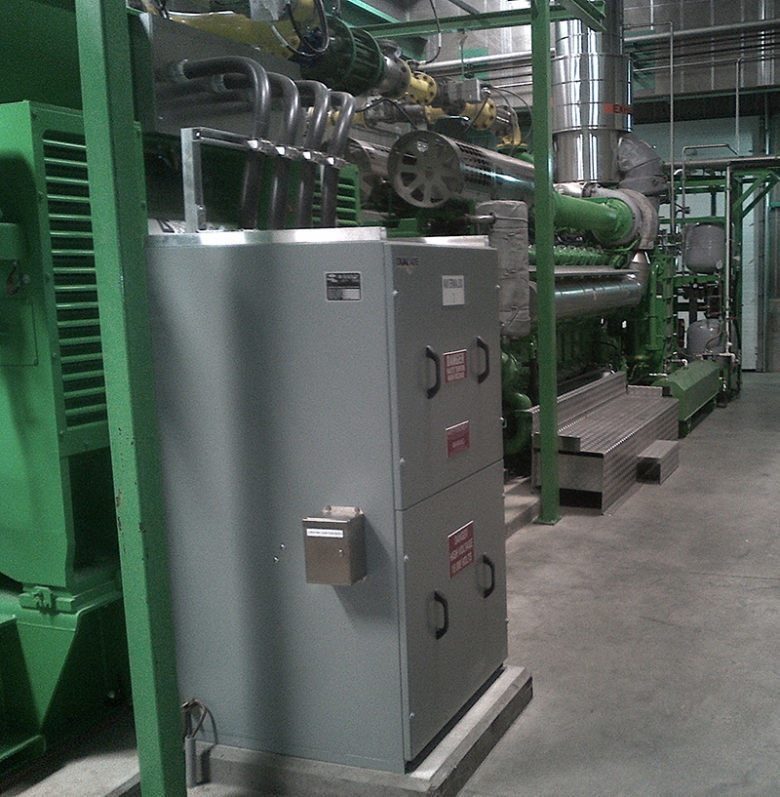

Slave Lake Pulp 9 MWe Cogeneration Project

Waste-activated sludge is produced in vast amounts at pulp mills, and is generally sent to be incinerated or landfilled, or can be land applied. Any of these options represented a lost opportunity at the Slave Lake Pulp plant in Alberta. The sludge would instead be repurposed to serve as the main ingredient for anaerobic digestion—a reliable, local, ongoing source of renewable energy.

HH Angus designed a 3 X 3 MWe bio-gas fed cogeneration plant for Slave Lake Pulp, a division of West Fraser Mills. The renewable energy technology integrates energy-efficient anaerobic digestion, using the pulp sludge, into the plant’s existing wastewater treatment system. This allows the plant to generate a methane-rich biogas that produces electricity and heat for the pulping process.

Our scope included: engineering electrical power equipment to integrate from the owner’s 13.8kV switchboard into the electrical generation system distribution to connect the cogeneration equipment; electrical design for a new engineered building housing the cogeneration machines and balance of plant; affiliated balance of plant engine electrical support services, such as high and low temperature cooling, exhaust gas heat exchanger and fresh/waste oil, glycol makeup systems, etc.

HH Angus prepared a 13.8kV single line diagram for the electrical system, from the power generation modules through the switchboards, to the interface to the utility service and existing owner’s distribution system; plus preparation of a 600V & 120/208V single line diagram for the generator, building auxiliary and balance of plant services. We also designed protection and control systems, and connection arrangements including SCADA with AESO.

SERVICES

Electrical Engineering | Commissioning support

PROJECT FEATURES

Status: Completed 2015

LOCATION

West Fraser Mills, Alberta

KEY SCOPE ELEMENTS

Designed a 3 X 3 MWe bio-gas fed cogeneration plant | Detailed design of power equipment to integrate to utility and owner’s existing plant | Initiated protection and control system designs Including connection arrangements - SCADA with AESO

Proven protection

We provided a detailed short circuit analysis and co-ordination protection setting study to satisfy the owner that their system is fully protected.

Energy win-win

“This system will now allow us to actually take advantage of some of this lost energy, while also reducing our consumption.”*

Rod Albers, Manager of Energy ad Bio-Product Development, West Fraser Mills

Yukon Energy

Gas Drive Cogeneration Plant

Yukon Energy is a publicly-owned electrical utility that operates as a business at arm’s length from the Yukon government. It is the main generator and transmitter of electrical energy in Yukon and works with Yukon Development Corporation to provide Yukoners with electricity and related energy services.

There are almost 15,000 electricity consumers in the Yukon Territory. Yukon Energy directly serves about 1,700 of these customers, most of whom are in the communities of Dawson City, Mayo and Faro.

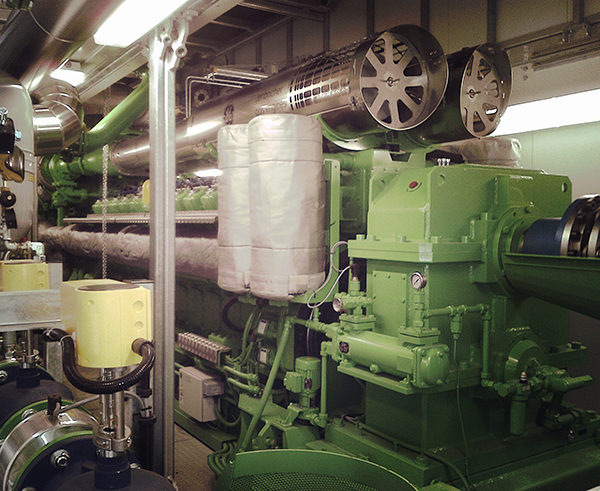

Included in our electrical scope for Yukon Energy’s new cogeneration plant:

- Design of a two X 4.4 MWe Jenbacher 4160V LNG (liquid natural gas)-fed modular, containerized generation facility

- Supply of affiliated electrical power equipment (interface power transformer & switchgear, including electrical protection and control) to integrate from the owner’s existing transformer T4 6900V secondary into the electrical generation system distribution to connect the generation equipment

- Supply of station service transformer and distribution equipment to power all auxiliary equipment (jacket water pumps, dry cooler, battery chargers, module lighting, etc).

The Yukon Energy interface included a utility interface panel for complete utility interconnection to local standards. We provided interface wiring design for protection (ie. transfer trip) and SCADA, as well as outlining the electrical design for the switchgear container. Additional design included the balance of the plant engine electrical support services (HT & LT cooling, exhaust gas heat exchanger and fresh/waste oil and glycol makeup systems), etc. These services are supplied by a separate 600V service provided by the owner.

SERVICES

Electrical Engineering

PROJECT FEATURES

Status: Completed 2015

LOCATION

Yukon, Canada

KEY SCOPE ELEMENTS

Design of 2 X 4.4 MWe Jenbacher 4160 LNG-fed containerized generation facility | Utility panel, interface wire design for protection and SCADA | Outlined electrical design for switchgear container | Designed plant engine electrical support services | Balance of plant engine electrical support services

Qualico Developments West Edmonton

Epcor Tower

“Skyscrapers have always inspired the public’s imagination, helping to define a city’s significance and identity. A key consideration for the project team behind EPCOR Tower was the need to create a timeless landmark facility that sets new standards in urban development for the 21st Century.”

— Christiaan Odinga, Lead Designer & Project Manager

EPCOR Tower, at time of construction, represented Edmonton’s first high rise office tower in 20 years. Located at the gateway to the downtown core, it was one of the tallest and most distinctive buildings in the city. The tower, comprising 28 storeys, incorporates a range of sustainable design, construction and operational features and was certified LEED® Silver. It was selected as one of Canada’s most environmentally advanced buildings, and was featured at the World Sustainability Conference in Finland in 2011. Vertical Transportation systems for the building consist of six low-rise elevators, six high-rise elevators, one dedicated service elevator and three parking shuttles.

SERVICES

Vertical Transportation Consultants

PROJECT FEATURES

Size: 623,900 ft2 | Status: Completed 2012

LOCATION

Edmonton, Alberta

KEY SCOPE ELEMENTS

6 low-rise elevators, 6 high-rise elevators, 1 dedicated service elevator and 3 parking shuttles | Certified LEED® Silver

TELUS

Super Internet Data Centre, Kamloops BC

“The Kamloops Internet Data Centre will be the cornerstone of our national next-generation cloud computing services, handling complex data storage and offering unsurpassed connectivity, superior functionality, state-of-the-art security and industry-leading reliability to our clients.”*

Lloyd Switzer, TELUS Senior VP, Network Transformation

The new TELUS Tier III design-certified data centre was the first TELUS Super Internet Data Centre built to LEED Gold standards. It is directly connected to the national TELUS IP network and interconnects into existing data centres across the country, creating what has been described as the most advanced and regionally diverse computing infrastructure in Canada.

The Intelligent Internet Data Centre incorporates innovative, non-traditional solutions, such as a closed-loop cooling system that provides unparalleled operating efficiency. The first of its kind in the world, this system is 180 times more efficient than that of a traditional cooling plant.

TELUS reports a PUE** of 1.15 for the data centre, which put TELUS at the forefront of the industry. The new data centre has a modular design, enabling TELUS to rapidly expand capacity and to tailor its offerings to the most advanced and efficient technologies available.

SERVICES

Mechanical Engineering | Electrical Engineering | Security Design | IMIT Engineering | Vertical Transportation Consulting | Lighting Design

PROJECT FEATURES

Status: Completed 2012

LOCATION

Confidential

KEY SCOPE ELEMENTS

Modular construction with reduced on-site fabrication | Inaugural installation of patented cooling system

Ensuring Quality Control

HH Angus acted as the Owner’s Commissioning QC Representative. Our responsibilities included review of the commissioning plan, the schedule and test scripts prepared by Commissioning Agent and the site observation reports to the stakeholder team - these covered the 27.6kV incoming switchgear complete with automatic transfer scheme, diesel rotary UPS system, automatic transfer switches, 600V distribution switchboards, Electrical Monitoring System (EMS), ISOT and Black Start Testing.

Tier III Accreditation

HH Angus was the Owner’s representative for the Uptime Institute On-Site Tier III Accreditation Audit.

**PUE, or Power Usage Effectiveness, is the Uptime Institute’s classification system, an internationally recognized benchmark to assess data centre reliability.

*BC Tech News: TELUS OPENS 75 Million Next Generation Cloud Computing Data Centre in Kamloops

The Town of Jasper

Jasper Activity & Aquatic Centre

A key part of the heart of the community, the Jasper Activity and Aquatic Centre is used extensively year round. Originally just an outdoor pool with a small stone change room built in the 1920s, it has been transformed into a major facility with ice rinks, curling rinks, meeting rooms, daycare and a senior centre.

HH Angus was responsible for the engineering and design for approximately 25,000 ft2 of renovations to the main entrance lobby, daycare, administration offices, as well as a new 5,000 ft2 open concept space for the fitness centre relocation.

Sustainability, health, wellness and community were key goals, supported by use of natural materials, daylighting and special features such as a green roof, photovoltaic cells and storm water collection and reuse.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 25,000 ft2 | Status: Completed 2011

LOCATION

Jasper, Alberta

KEY SCOPE ELEMENTS

Mechanical and electrical engineering & design for ~25,000 ft2 of renovations | New 5,000 ft2 open concept space for fitness centre | LEED Silver Certified