Cadbury Canada

Weston Foods Gladstone Avenue Plant

The Weston Foods plant has undergone many mechanical and electrical renovations and upgrades with HH Angus and Associates serving as prime consultant.

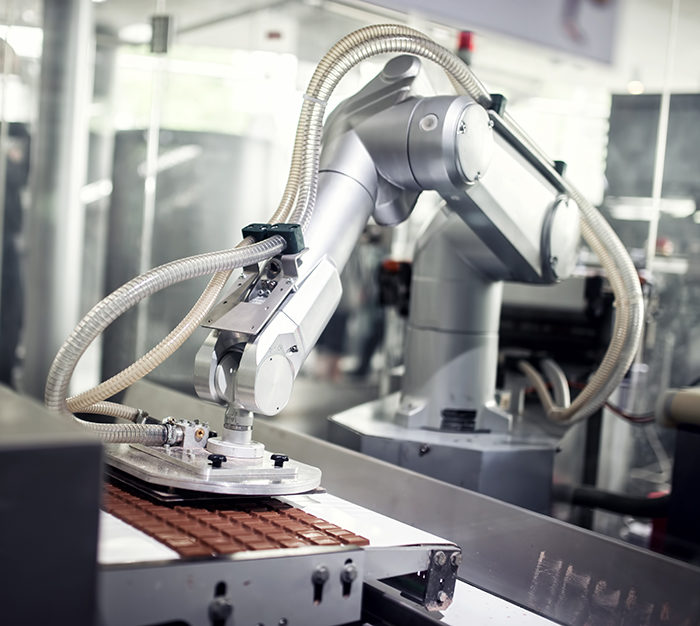

Producing chocolate and confectioneries has many challenges. They require viscous fluid pumping and precise control of temperature and humidity levels in order to produce quality chocolate. These engineering challenges were compounded by the plant’s urban location in a residential area, which meant that all amendments to the exterior of the plant had to be compatible with the neighbourhood.

HH Angus was engaged to review the plant, which had been operating for 20 years. This was done to establish current production requirements and to assist in projecting requirements for future growth.

HH Angus’ work at the plant included:

- Development and construction of a new central plant to provide steam, water, compressed air, refrigeration, and HVAC services for confectionery production. The plant featured a 2000 ton ammonia-to-water process chilling and air conditioning plant to condition 300,000 cubic feet per minute for air conditioning and ventilation of production areas, and for remediation of noise and odours within the plant. Renovation of the office and manufacturing facilities involved relocation of 13 production lines to preferred locations and reworking the electrical power distribution system. During the time the renovation was in progress, production was sequentially phased in selected areas, and high levels of quality production were achieved with no impact on product quality.

Processes and spaces involved in the renovations and upgrades included:

- Pumping of multiple grades of chocolate with double-walled hot water heated piping for chocolate transportation

- Pumping of chocolate liquor, fats and food oils, glucose, sugars, caramel, nougat; transport piping and storage tanks

- Bulk milk delivery with tanker cleaning facilities

- Freezer storage warehouse space for ice cream

- Cool storage for chocolates

- Cold storage for production ingredients

- Process water recovery system for process chilled, cold and hot water, which reduced plant water consumption with significant savings

- 50,000 US gallons per day process effluent discharge control system to reduce biochemical oxygen demand and suspend solid level of process effluent to meet stringent City of Toronto requirements

- Special humidity control (30% RH or lower) for hydroscopic confectionery process rooms

- Air systems to handle process-generated dust and vapour extraction for peanuts, raisins, alcohol solvent-based candy coatings, and sugar conveying

- Review of process cooker and votator (scraped surface heat exchanger) of foreign manufacture with respect to ASME pressure vessel code compliance

- Upgrading of 2200 ton ammonia refrigeration condensing system to all evaporative condensing equipment, with 28 stages of condensing. Design of microprocessor-based control system for: optimized selection of equipment to maintain condensing pressure; automatic selection of quietest equipment for night-time operation; automatic selection/deletion of condensing stages for summer or winter operation.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2006

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Development and construction of new central plant facility | Steam, compressed air, refrigeration and HVAC services | Renovation of office and manufacturing facilities

Working with Affiliates

In addition to the work in the chocolate and confectionery plant, HH Angus and Associates has been involved with Weston Group food plants at:

- Weston Bakeries

- Neilson Dairies

- Loblaw Supermarkets