Gas Drive

Slave Lake Pulp 9 MWe Cogeneration Project

Waste-activated sludge is produced in vast amounts at pulp mills, and is generally sent to be incinerated or landfilled, or can be land applied. Any of these options represented a lost opportunity at the Slave Lake Pulp plant in Alberta. The sludge would instead be repurposed to serve as the main ingredient for anaerobic digestion—a reliable, local, ongoing source of renewable energy.

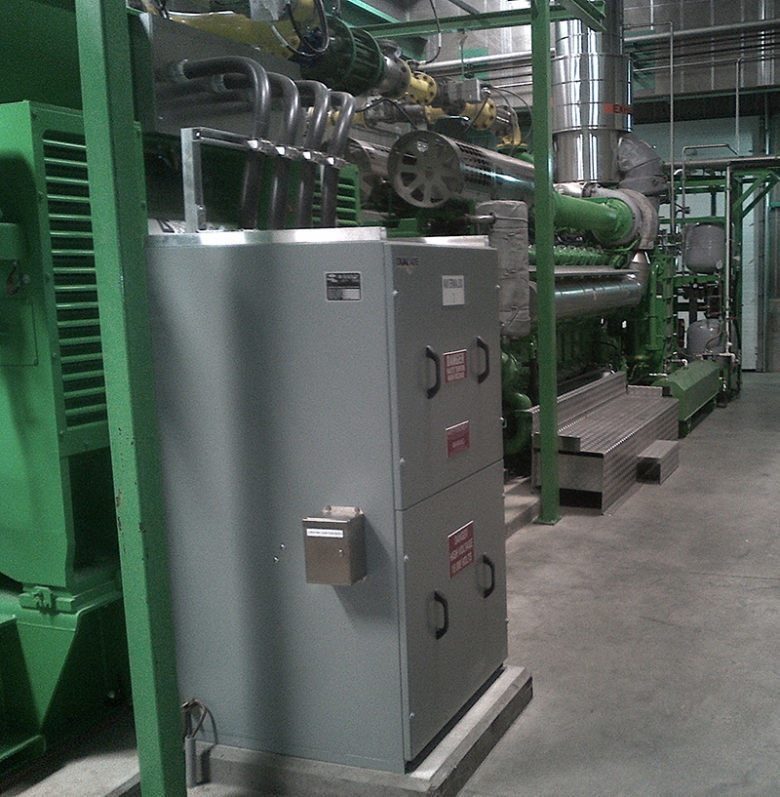

HH Angus designed a 3 X 3 MWe bio-gas fed cogeneration plant for Slave Lake Pulp, a division of West Fraser Mills. The renewable energy technology integrates energy-efficient anaerobic digestion, using the pulp sludge, into the plant’s existing wastewater treatment system. This allows the plant to generate a methane-rich biogas that produces electricity and heat for the pulping process.

Our scope included: engineering electrical power equipment to integrate from the owner’s 13.8kV switchboard into the electrical generation system distribution to connect the cogeneration equipment; electrical design for a new engineered building housing the cogeneration machines and balance of plant; affiliated balance of plant engine electrical support services, such as high and low temperature cooling, exhaust gas heat exchanger and fresh/waste oil, glycol makeup systems, etc.

HH Angus prepared a 13.8kV single line diagram for the electrical system, from the power generation modules through the switchboards, to the interface to the utility service and existing owner’s distribution system; plus preparation of a 600V & 120/208V single line diagram for the generator, building auxiliary and balance of plant services. We also designed protection and control systems, and connection arrangements including SCADA with AESO.

SERVICES

Electrical Engineering | Commissioning support

PROJECT FEATURES

Status: Completed 2015

LOCATION

West Fraser Mills, Alberta

KEY SCOPE ELEMENTS

Designed a 3 X 3 MWe bio-gas fed cogeneration plant | Detailed design of power equipment to integrate to utility and owner’s existing plant | Initiated protection and control system designs Including connection arrangements - SCADA with AESO

Proven protection

We provided a detailed short circuit analysis and co-ordination protection setting study to satisfy the owner that their system is fully protected.

Energy win-win

“This system will now allow us to actually take advantage of some of this lost energy, while also reducing our consumption.”*

Rod Albers, Manager of Energy ad Bio-Product Development, West Fraser Mills