Neilson’s Dairy

Plant Renovations & Expansions

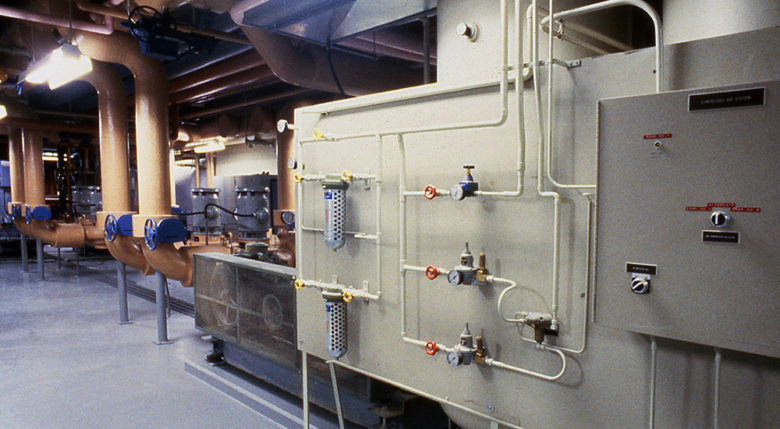

Since the mid-1970s, HH Angus and Associates has been involved in upgrading and renovating all building and process services, including the renovation of the Gladstone Confectionery plant, a 250,000 ft2 facility.

Mechanical and electrical engineering services were provided for chocolate pumping and piping, air milling, roasting and treatment of beans, pneumatic conveying of cocoa and sugar, pumping food that required heating of the lines to permit the food to flow, and myriad other demanding problems.

We also provided engineering design for the construction of a large new production facility in Georgetown, ON. This plant, which is approximately 180,000 ft2, uses modern dairy techniques involving extensive stainless steel piping and large refrigerated warehousing.

We also were involved in the upgrading and addition of new freezer rooms for ice cream production, and the installation of the Cadbury confection line into the Gladstone plant.

SERVICES

Prime Consultants | Planning | Mechanical Engineering | Electrical Engineering | Construction Admin

PROJECT FEATURES

Size: 250,000 ft2 | Status: Completed 1972

LOCATION

Georgetown, Ontario

KEY SCOPE ELEMENTS

Extensive stainless steel piping | Upgraded additional freezer rooms for ice cream production | Installed a Cadbury confection line into Gladstone plant