Sector: Commercial

Novartis Pharmaceuticals Canada Inc.

755 Berri Street, Montreal

Novartis Canada needed to rethink their physical work

space to better support their focus on innovation. They

relocated their headquarters from Dorval to downtown

Montreal close to transit, amenities and, most importantly, many of their healthcare and technology partners.

The project involved the fit-up of a two-storey, 32,291 ft2 commercial office space. Our design services included on-site verification of existing mechanical, electrical and communications systems, as well as reviewing the integration of the lighting design. The new space has 100 unassigned workstations and 21 meeting rooms, which range in size to fit anywhere from four to 10 people, are equipped with digital touchscreen reservation system.

HH Angus assessed the mechanical and electrical base building systems and coordinated communication requirements with the client’s IT representative. Final deliverables comprised mechanical, electrical, and communications drawings and specifications. The deliverables were executed in English and French for permit, tender, and construction.

While doing the project, Gensler, the client, requested additional services to accommodate an expedited and compressed schedule. As a solution to this, HH Angus mobilized additional designers in the various disciplines and added assistance of internal project management staff. Moreover, more meetings were set to better coordinate the design. Overall, HH Angus, as part of their role of executing the Gensler’s goal, assimilated into the client’s mission in order to successfully execute the project.

SERVICES

Electrical Engineering, Mechanical and Communications Drawings and Specifications

PROJECT FEATURES

The project involved the fit-up of a two-storey, 32,291 ft2 commercial office space | Status: Completed 2023

LOCATION

Montreal, QC

KEY SCOPE ELEMENTS

The deliverables comprised mechanical, electrical, and communications drawings and specifications.

TELUS

Len Werry Building Turbine Replacement

The TELUS Len Werry Building in downtown Calgary houses offices, computer facilities, toll switch equipment, and local switching equipment for a major toll complex.

The project involves the replacement of the building's existing turbines with new reciprocating diesel generators and redundant synchronization switchboards in a new penthouse on top of the building.

HH Angus is providing electrical engineering services to support upgrades to the electrical distribution system related to the installation of the new diesel generators.

SERVICES

Electrical Engineering

PROJECT FEATURES

Infrastructure replacement in occupied commercial tower | Status: Ongoing

LOCATION

Calgary, Alberta

KEY SCOPE ELEMENTS

Upgrades to electrical distribution system

The Co-operators Calgary

Tenant Fitout

This project focused on a tenant renovation of two floors in The Co-operators' newly-acquired downtown Calgary office space, and comprised 40,000 square feet. The project has been certified WELL Gold.

Our approach included early coordination with the landlord to ensure handover conditions suited the client’s requirements, as well as close coordination with the construction manager in creating a pre-order due to a condensed construction schedule.

The construction schedule was a key challenge of the project along with the timing of tender. The completion date was an unmovable milestone as the client’s lease was expiring at their other location. At time of tender, product and material availability were fluctuating, which created uncertainty around delivery. To meet the deadline, our team was tasked to do everything possible to ensure the success of the project and keep the schedule on track.

To help ensure timely delivery, our team incorporated a pre-order package for the construction manager to tender, which allowed products to be reviewed and released ahead of the official tender. This effort was successful and was completed according to plan; however, some delivery delays were unavoidable, due to market conditions. To mitigate the impact, we were then tasked with contacting industry partners to help expedite deliveries. In addition, alternative temporary designs were implemented to ensure the move-in date could be met by planning the switchover date once the outstanding equipment arrived.

The Calgary office marks our fifth tenant improvement project for The Co-operators, following similar fitouts for their locations in Guelph ON and Regina SK, as well as pilot projects in Montreal QC and Burlington ON.

New Lutron lighting control design

New UPS N+1 Design and new LED Lighting Design

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | Communications & Security Design

PROJECT FEATURES

Size: 40,000 ft2 over two floors | Status: Completed 2023

LOCATION

Calgary, Alberta

KEY SCOPE ELEMENTS

Feasibility Study | Tenant renovation | Condensed construction schedule | WELL Gold certified

Waypoint Centre for Mental Health Care

Chigamik Community Health Hub

Waypoint Chigamik Mental Health Centre is part of a redevelopment project and replaces two older facilities in use since the 1800s.

The challenges of this project included the requirement that the entire building be completely designed in one stage, rather than proceeding with design packages, plus delays in funding during the design process which resulted in a requirement for both a base building package and a fitout package.

To accomplish this, HH Angus coordinated two tender packages and two building permit submissions. Some detailed specifications in each package were interchangeable for the mechanical and electrical tender process. Working with phased schedules ensured that equipment start-up was fully coordinated between the tender packages.

The project faced additional challenges to provide an energy-efficient HVAC system, due to compliance with CSA Z317.2 and budget restrictions, as well as a small mechanical service space. To overcome these challenges, extensive coordination was implemented throughout the project across all disciplines.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | ICAT Commissioning

PROJECT FEATURES

Size: 40,000 ft2 | DBFM | Fully ducted HVAC system designed to comply with CSA Z317.2 | Status: Completed 2020

LOCATION

Midland, Ontario

KEY SCOPE ELEMENTS

Building has full back up power with generator sized to accommodate the entire load of the building on loss of utility power conditions

Efficient design

Several engineering designs were reviewed by the project team to ensure compliance with the owner’s goals and restrictions, while achieving an efficient design.

Customized spaces

The two-storey 40,000 ft2 mental health care facility has amenities for indigenous smudging ceremonies, physiotherapy, conferences, a community kitchen, gathering rooms, and a youth programming space.

Renderings courtesy of Lett Architects Inc.

City of Mississauga

Burnhamthorpe Community Centre Renovation and Expansion

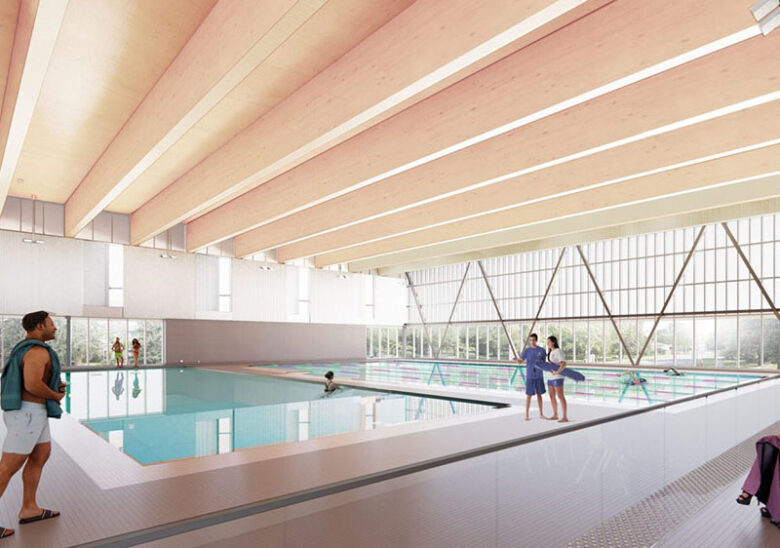

The Community Centre features a state-of-the-art aquatic centre as well as an equipment-based fitness centre. This is the first project designed and built to Mississauga's corporate Green Building standard. The project has also achieved Level 1 CGBS and incorporates net zero and passive house principles, a high-performance building envelope, triple glazing, and a green roof.

HH Angus played a key role in this project, providing mechanical and electrical engineering services, as well as security, IMIT, lighting, AV, and plumbing design. The addition includes a new 25-metre, 6-lane pool, therapeutic pool, fitness centre, and common areas, for a total of 43,000 ft2 of added amenities.

Renovations to the existing community centre encompass improvements across 65,000 ft2, repurposing and relocating multi-purpose program spaces, gymnasium, indoor arena, and upgrading facilities to meet accessibility and green development standards. Despite challenges posed in connecting to the existing building, the addition was situated on the northeast corner, utilizing space from the adjacent park.

To see more renovations, click here

SERVICES

Mechanical Engineering | Electrical Engineering | Plumbing Design | Lighting Design | Audio-Visual Design | Security Design | IMIT Design

PROJECT FEATURES

Green facility design to LEED Silver standard | State-of-the-art aquatic centre | Equipment-based fitness centre | Status: Completed 2024

LOCATION

Mississauga, Ontario

KEY SCOPE ELEMENTS

Project built to Mississauga's Green Building standard | Achieved Level 1 CGBC | Addition connected to existing recreation centre | Renovations and upgrades to existing building

All images courtesy of CS&P Architects