Sector: Healthcare

St. Michael’s Hospital

Barlo MS Centre

Canada has the highest rate of multiple sclerosis in the world; in fact, the disease is known internationally as ‘Canada’s Disease’. St. Michael's Hospital in Toronto is one of North America's busiest MS centres. It has been caring for people with MS since 1981, and now treats 7,000 patients.

The new Barlo MS Centre offers one-stop care, bringing together neurologists, nurses, social workers, neuropsychologists, physiotherapists, occupational therapists and speech therapists in a world-leading treatment and research centre for multiple sclerosis. The 25,000 ft2 clinic has been constructed on the top two floors of the new Peter Gilgan Patient Care Tower.

HH Angus’ mechanical scope for the fitout of the shelled space included ventilation, plumbing, medical gas, heating & fire protection, and controls. Our electrical scope covered power, lighting, communications and security.

Unique aspects of the project's design included: presentation to the client of a number of ventilation strategies to address the shortage of air supply available to the design, and a reworked ventilation strategy under a very aggressive schedule to redistribute and extend air to the clinic from an existing air handling unit that was previously feeding another floor.

Some of the project challenges included:

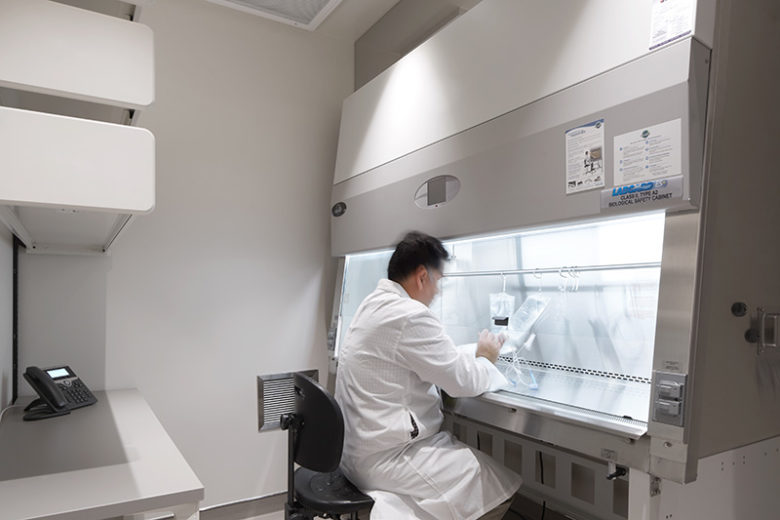

- The addition of a compounding pharmacy late in the design, for which additional requirements had to be vetted to meet NAPRA. The team took advantage of early works to investigate available shaft space for running new biological exhaust to the roof.

- Design activities had to be scheduled concurrently with testing and commissioning still underway at the time for the main Patient Care Tower.

- Ceiling construction and new structural constraints limited accessibility. The team used 3D imaging and Revit to coordinate all ceiling elements requiring accessibility, in order to integrate services into areas with wooden slatted ceilings.

- The team took advantage of early works to coordinate structural openings for future ventilation in order to limit ceiling interference for the fitout design.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting | Plumbing | Communications Systems | Security Systems

PROJECT FEATURES

Size: 25,000 ft2 | Status: Completion 2021

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Two floor clinic fitout | Variety of room types and functions | Custom smoke venting and fire alarm zoning to accommodate feature staircase

Achieving the design vision

We worked closely with the architect to modify the existing fire alarm zoning and smoke venting strategy in order to accommodate a new mezzanine on Level 17. This allowed the architect to achieve the design vision for the feature staircase without the use of smoke baffles.

Variety of functions

The space includes a variety of room types, including exam rooms, gym, medical infusion centre, group physiotherapy studio, auditorium, cognitive lab and a pharmacy.

Click here for the St. Michael’s Hospital video feature on the Barlo MS Clinic.

Ontario Shores Centre for Mental Health Sciences

Heritage Lounge

This mental health facility is located within the waterfront district in Whitby, Ontario. The building underwent renovations to create a lounge that would provide a relaxing space, while displaying an interactive experience representing the 100-year heritage of the site.

The new heritage lounge provides a welcoming and inviting space where patients and families can visit, relax and participate in events at the Centre. It incorporates private and communal seating areas, state-of-the-art video wall and audio systems, as well as an interactive kiosk and display cases to celebrate the history of the hospital.

HH Angus provided AV design and electrical engineering to support the renovation, including lighting, power and an integrated 3x3 video wall with the ability to show prerecorded video, cable TV, movies and content developed by the hospital.

The design for the displays called for them to be recessed so that they appear to be part of the wall, rather than a standalone display. This meant very tight construction tolerances needed to be maintained in order to achieve the desired effect. The power supply and system connections for the display cases and wall were arranged to minimize the overall impact on the area's aesthetic.

SERVICES

AV Design Consulting | Electrical Engineering

PROJECT FEATURES

Status: Completed 2019 | Integrated Video Wall & Audio | Seamless Recessed Construction | Interactive Kiosks

LOCATION

Whitby, Ontario

KEY SCOPE ELEMENTS

State of the art integrated 3x3 video wall and audio capability throughout | Seamless recessed construction, integrated with other interior components

Close

Coordination

Careful coordination with the architect was required to ensure that the video wall and heritage kiosks integrated seamlessly with the interior space rather than acting as a standalone display.

Lighting Design

The lighting for the Heritage Lounge was designed to suit the purpose and ambiance of the space, as well as to highlight the display cases, ensuring there would be no interference with the operation of the video wall feature.

Fraser Health Authority

Royal Columbian Hospital Redevelopment

The Royal Columbian Hospital is the oldest hospital in the province of B.C. and one of the busiest in the Fraser Health Authority. Royal Columbian provides expert care to the province's most seriously ill or injured. It is the only hospital in B.C. that caters to trauma, cardiac care, neurosurgery, high-risk, obstetrics, neonatal intensive care, and acute mental health care all on one site.

HH Angus and Associates is serving as the Planning, Implementation and Closeout Consultant for the Fraser Health Authority’s large, multi-phase redevelopment for Royal Columbian Hospital (RCH) in New Westminster, BC.

RCH is British Columbia’s oldest hospital, and one of only two adult trauma centres in the Lower Mainland. The plan, rolling out in three proposed phases over a decade, will see a major expansion of the acute care campus, with upgrades to critical infrastructure.

Phase 1 included a number of projects to help prepare the hospital’s infrastructure for future expansion. These were a new energy centre; a five-storey, 75-bed mental health and substance abuse facility; underground parking for 450 cars; and a regional data centre which will serve all Fraser Health sites, including 12 hospitals and a large group of community healthcare centres serving a population of 1.6 million.

Phase 1 design challenges included the site itself, which is a steeply sloped, truncated triangle constrained on four sides by roadways. Working closely with CannonDesign, we developed an Indicative Design to ensure the site would work for a mental health building while accommodating the energy centre.

Other challenges included complex scheduling issues to maintain reliable services to the site as the new Energy Centre replaced the old one, and the design of a new, large heating, cooling and electrical plant to serve the current and future RCH campus. HH Angus engineers drew on their deep experience in delivering large healthcare projects to project the future heating, cooling and electrical demands on the Energy Centre that would support the long-term needs of RCH for buildings not yet designed.

Phase 2’s new Acute Care Tower will house a number of services, including emergency, surgery, intensive care and inpatient rooms. Expansion and renovations to the existing buildings will follow in Phase 3. New buildings will be designed to LEED Gold green building standards, and incorporate BC wood, as part of Fraser Health's and the Province's commitment to sustainability.

Image courtesy of Fraser Health.

SERVICES

PDC - Mechanical Compliance Engineering | Electrical Compliance Engineering | Vertical Transportation Compliance

PROJECT FEATURES

Status: Phase 1 – work is finished, Phase 2 – ongoing | Buildings being designed to LEED Gold

LOCATION

New Westminster, BC

KEY SCOPE ELEMENTS

Planning, Implementation and Closeout Consultant | Phase 1 includes a number of projects to help prepare hospital infrastructure for future expansion | Phase 2 Acute Care Tower

Halton Healthcare

Oakville Trafalgar Memorial Hospital

As a large super hospital, this greenfield ~ 1.5 million ft2 facility features ORs, Emergency Department, Diagnostic Imaging, Mental Health, Long term Critical Care, and Dialysis services. There is also a large central kitchen and central Sterile Processing department. The hospital has been certified LEED Gold NC, exceeding its target of LEED Silver NC.

The central utility plant provides 4200 tons of cooling, 1500 bhp of hot water and 1500 bhp of steam. There is 15 MW of generator capacity onsite, along with 72 hours of fuel oil storage and a large fuel oil distribution system.

Some of the complexity inherent in this project was due to the design work being split between multiple engineering companies, which significantly increased the amount of coordination required. A key challenge was simply the scale of the new hospital, which increased the complexity of all of the systems. It required integration of systems across multiple engineering companies who were producing different portions of the design.

Another challenge was the extremely tight project schedule. This meant that tasks, which are normally completed sequentially, had to be done concurrently. This required very exacting planning and accelerated design work. Regular meetings with multiple engineering and architecture disciplines allow parties to bring their issues and design requirements to the table and to work through them in a collaborative way.

The vertical transportation design scope included 33 elevators servicing the main hospital building and 3 providing service to the parking garage.

The project co. required commissioning support for the contracting team in order to achieve milestones. HH Angus assembled a separate team of technical personnel to blitz specific systems in a 7-week period. With little preparation time, HH Angus leveraged members of the design team to train the commissioning personnel prior to going to site.

SERVICES

Mechanical Engineering | Vertical Transportation Consultant | Commissioning Support

PROJECT FEATURES

Size: 1.5 million ft2 | Completed 2015 | Greenfield super hospital project | LEED Gold

LOCATION

Oakville, Ontario

KEY SCOPE ELEMENTS

Central Utility Plant provides 4200 tons of cooling, 1500 bhp of hot water and 1500 bhp of steam | 36 elevators serve the hospital and parking facilities

Alternate approach to Cx

Through a cycle of improvements in methodology, HH Angus was able to improve productivity on site by more than 100% with an alternate approach to commissioning, which was shared with other onsite commissioning groups.

SickKids

Peter Gilgan Centre for Research & Learning

“This investment in the Research and Learning Tower will help ensure that Canada remains a world leader in health research, and that we will continue to make discoveries that benefit children around the world.”

– Gary Goodyear, Minister of State for Science and Technology

HH Angus provided mechanical and electrical consulting engineering for this 740,000 ft2 high-rise research and educational facility. This building enhanced the overall campus of SickKids, which totals over 2,500,000 ft2. SickKids is a landmark hospital and renowned internationally as a world-class institution.

The facility has been certified LEED® Gold. Energy modeling indicated a significant improvement over the minimum energy performance required by the program. Systems were segregated to achieve significant thermal reuse within the facility. The option to integrate a waste heat recovery system from the neighbouring district heating provider was incorporated into the design to realize even greater energy efficiency in future.

The building services design supported the main objectives for the new facility:

- Consolidate the Research Institute into a cohesive unit

- Integrate research functions with the hospital

- Provide flexibility for future change

- Maximize functionality and efficiency

- Share support functions

- Utilize current technologies and infrastructure, including a plan for increased security for highly specialized spaces such as Containment Level 3

- Incorporate exemplary sustainable “Green” building design concepts and system

- Create a high-tech, cost-effective space for evolving state-of-the-art technologies

The interesting design challenges inherent in this high-rise lab building contributed to both the complexity and enjoyment of the design process, including a 1½ storey vivarium and 40,000 ft2 of educational space.

Quote source: SickKids

SERVICES

Mechanical Engineering | Electrical Engineering | IT & Communication Design | Vertical Transportation | Lighting Design

PROJECT FEATURES

Size: 740,000 ft2 with 40,000 ft2 educational space | Status: Completed 2013

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Complex systems design for a tight downtown urban space | 1.5 storey vivarium | LEED Gold Certified | Incorporated options to permit a future waste heat recovery system