Sector: Institutional/Public Sector

City of Toronto

Nathan Phillips Square Spirit Garden

The City of Toronto has been revitalizing areas of the City’s landmark Nathan Phillips Square at New City Hall. As part of the improvements, a new Teaching, Learning, Sharing, and Healing space was designed and constructed to recognize and honour the experience of Indian Residential School Survivors.

The project consisted of upgrades to existing surfaces with all new landscaping, including a water feature, large sculpture and public building.

HH Angus’ scope of work included mechanical and electrical engineering, security systems consulting, IMIT design, and commissioning. Specifically, the scope featured a full technical audit and inventory report to document all infrastructure and equipment impacted by the project; power supply for new landscape and other LED lighting fixtures; connection of new area drainage to existing storm systems in the parking level; mechanical and electrical services for the new 450 ft2 Teaching Lodge; and design of security systems for public spaces and the Teaching Lodge.

HH Angus also developed and prepared a commissioning plan for all mechanical and electrical equipment being installed during the project.

One of the interesting challenges of this project was working with multiple stakeholders to ensure the vision of all parties for the project was addressed.

SERVICES

Mechanical Engineering | Electrical Engineering | IMIT

design | Security Design | Commissioning

PROJECT FEATURES

Heritage site | Teaching lodge | New landscaping | Surface and parking improvements | Upgraded

existing exterior infrastructure

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Technical audit | Inventory Report | Power supply | Connection to drainage area in underground parking level | M&E services for new teaching lodge | Design of security systems

City of Mississauga

Burnhamthorpe Community Centre Renovation and Expansion

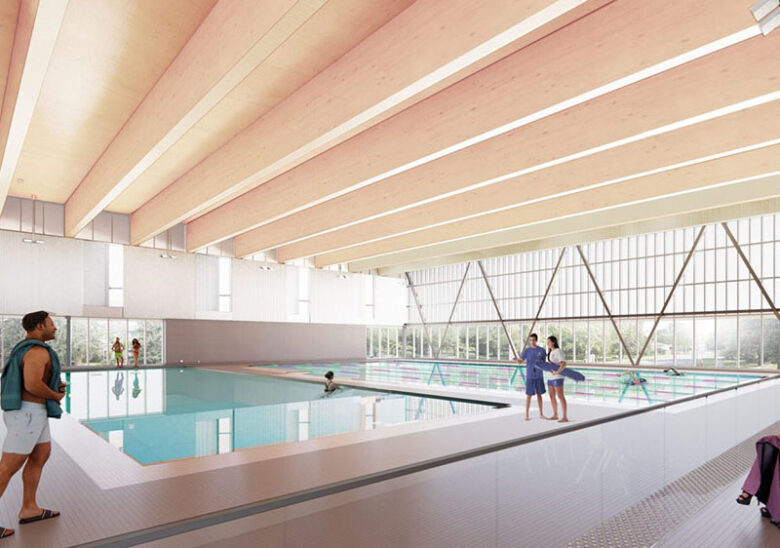

The Community Centre features a state-of-the-art aquatic centre as well as an equipment-based fitness centre. This is the first project designed and built to Mississauga's corporate Green Building standard. The project has also achieved Level 1 CGBS and incorporates net zero and passive house principles, a high-performance building envelope, triple glazing, and a green roof.

HH Angus played a key role in this project, providing mechanical and electrical engineering services, as well as security, IMIT, lighting, AV, and plumbing design. The addition includes a new 25-metre, 6-lane pool, therapeutic pool, fitness centre, and common areas, for a total of 43,000 ft2 of added amenities.

Renovations to the existing community centre encompass improvements across 65,000 ft2, repurposing and relocating multi-purpose program spaces, gymnasium, indoor arena, and upgrading facilities to meet accessibility and green development standards. Despite challenges posed in connecting to the existing building, the addition was situated on the northeast corner, utilizing space from the adjacent park.

To see more renovations, click here

SERVICES

Mechanical Engineering | Electrical Engineering | Plumbing Design | Lighting Design | Audio-Visual Design | Security Design | IMIT Design

PROJECT FEATURES

Green facility design to LEED Silver standard | State-of-the-art aquatic centre | Equipment-based fitness centre | Status: Completed 2024

LOCATION

Mississauga, Ontario

KEY SCOPE ELEMENTS

Project built to Mississauga's Green Building standard | Achieved Level 1 CGBC | Addition connected to existing recreation centre | Renovations and upgrades to existing building

All images courtesy of CS&P Architects

Ministry of the Solicitor General | Infrastructure Ontario

Thunder Bay Correctional Complex (TBCC)

The TBCC involves replacement of aging jail and correctional facilities with a new 345-bed, multipurpose complex. Both the existing Thunder Bay Jail and Thunder Bay Correctional Facility are among the oldest provincially-run adult correctional facilities, built in 1928 and 1965 respectively.

The new TBCC updates automation and technology to address issues of health, safety and security, and introduces efficiencies around design, technology, and the use of space. HH Angus is providing mechanical consulting engineering and vertical transportation consulting to the EllisDon Infrastructure Justice design team.

The TBCC is targeting LEED Silver certification and LEED Resilient Design pilot credits through the United States Green Building Council. The design focuses on energy efficiency, healthy indoor environments and reduced greenhouse gas emissions. The complex will also include views of nature, allow ample natural light and feature dedicated Indigenous cultural spaces, such as smudging space and sweat and teaching lodges.

The new facility is the first of its kind for an Ontario correctional facility, incorporating design features that promote rehabilitation of inmates. It will also improve access to programming, living conditions and education, while updating automation and technology.

The TBCC project has presented several challenges to our design team, including a compressed schedule and the involvement of numerous stakeholders. It has also been interesting on a technical level: mechanically, the various modes of operation and interconnection of systems are quite complex, necessitating a high degree of flexibility within the capacity of the mechanical equipment. The building construction featured a precast exterior with block walls, requiring very close coordination with trades to align openings and allow access for equipment.

Due to the secure nature of the facility, the mechanical system was integrated seamlessly into the architectural features, all accessible equipment is provided in a secure location, and all building systems interact

with the BAS.

The facility will include a connection to an existing 50-inmate facility — the Thunder Bay Modular Built Facility — located southeast of the TBCC and currently under construction. The project also involves the design and construction of a 4,000 ft2 wastewater treatment facility to allow for a fully self-sufficient and self-contained facility.

SERVICES

Mechanical Engineering | Vertical Transportation

PROJECT FEATURES

$1.2 billion | 345-bed, multipurpose facility | 450,000 ft2 | Completion expected in 2026

LOCATION

Eastern Canada

KEY SCOPE ELEMENT

Design required careful consideration of all inmate-accessible areas | Compressed schedule | Close collaboration with trades to ensure pre-cast exterior elements align accurately with equipment access openings

Images courtesy of Zeidler Architecture

Ontario Ministry of Health

Ontario Agency for Health Protection & Promotion (OAHPP)

(Sheila Basrur Centre)

Following the 2003 SARS outbreak, Public Health Ontario needed a site to bring together academic, clinical, public health and government experts on infection control and prevention. HH Angus was instrumental in providing a high quality, energy-saving workplace to meet LEED-CI Silver standards, key to highlighting PHO's commitment to sustainable practices.

A new 250kW natural gas-fired generator installed on the roof is the heart of the command centre. Its purpose is to exclusively back up the Electrical and Supplemental HVAC systems serving the command centre. As the area has unusual 416/240V service, special voltage requirements were engineered to facilitate both lighting and power equipment. Harmonic-type transformers provided clean, non-distorted power to two distribution panels, 80KVA UPS, receptacle, lighting panels and HVAC units. The 80KVA UPS unit provides 30 minutes of non-interrupted power to the command centre to allow the generator to start and reach full load capacity.

Since the original building did not meet LEED HVAC requirements, we provided detailed and well-thought-out designs to meet LEED criteria. High efficiency fixtures reduced the burden on city water supply and waste water systems. In addition, lighting was a major component for the LEED-CI Silver criteria, with glare and contrast ratio control, linear fluorescent direct/indirect lighting systems, LED downlights, and daylight harvesting.

Information technology infrastructure was key to the successful long-term functioning of this facility. The infrastructure included telecommunications rooms, conduits, cable support systems and structured cabling systems. The IT rooms house all of the building’s telecommunications fiber optics and copper backbone systems, horizontal cabling system and networking equipment, including telephone, data and video services. In the meeting spaces, the large display wall is intended for daily presentation requirements but, in the case of an emergency response scenario, the room will serve as a 24x7 mission critical war room.

SERVICES

Mechanical Engineering | Electrical Engineering | Communications Design | Lighting Design

PROJECT FEATURES

Status: Completed 2009 | 40,000 ft2 | 250kW natural gas generator for emergency back up power | 416/240 volt service required special engineering for lighting and power | 80 KVA UPS

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

250kW natural gas-fired generator | Achieving LEED requirements, particularly for HVAC and Lighting | IT infrastructure

Canadian War Museum

The Canadian War Museum is a unique and historically important project, with a signature design appropriate to its purpose. Situated on Ottawa’s LeBreton Flats, on the bank of the Ottawa River, this world-class facility is a major attraction for Canadian and international visitors.

Inspired by countless acts of Canadian bravery in conflict zones around the world, Architect Raymond Moriyama created a design which blends seamlessly into the surrounding landscape. The building features a landscaped roof - low-maintenance, self-seeding, and fully accessible. The Memorial Hall is strategically located at the intersection of two axes. One aligns the Memorial with the Parliament Building’s Peace Tower, and the other is the solar azimuth at precisely 11:00 am on November 11 - Remembrance Day - when 11 precisely-oriented rods capture the sun’s rays at that poignant moment for Canadians, symbolizing spiritual rejuvenation and a new beginning.

The vertical transportation system includes five (5) passenger elevators and one (1) freight elevator to accommodate movement of large artifacts.

The elevator system design for this project required that special consideration be given to the site location and its geological characteristics. All elevators are of the “holeless” hydraulic type, with special design features to attain the travel distances required, within very tight overhead allowances.

The Canadian war museum is an affiliate of the Canadian Museum of Civilization and houses 440,000 ft2 of exhibit, archive and office space, as well as a 4,200 ft2 theatre.

SERVICES

Vertical Transportation Consulting

PROJECT FEATURES

Status: Completed 2002

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Elevator Design | 5 passenger elevators and 1 freight elevator