Sector: Sports/Recreation

City of Mississauga

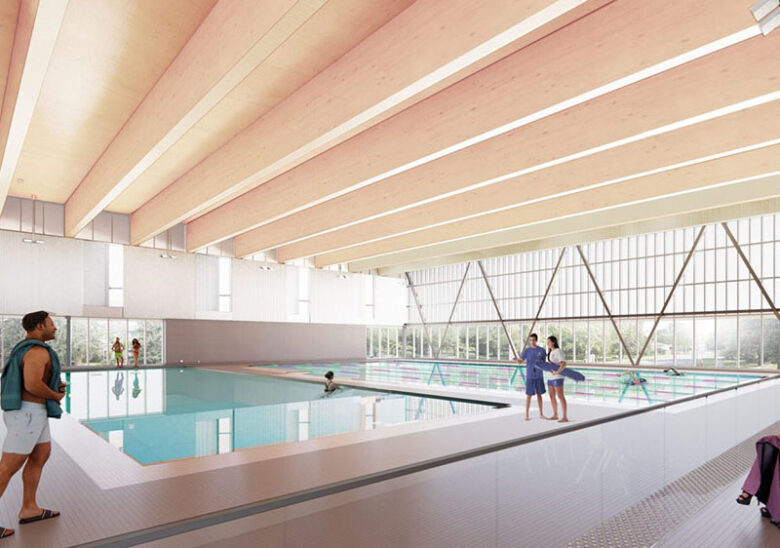

Burnhamthorpe Community Centre Renovation and Expansion

The Community Centre features a state-of-the-art aquatic centre as well as an equipment-based fitness centre. This is the first project designed and built to Mississauga's corporate Green Building standard. The project has also achieved Level 1 CGBS and incorporates net zero and passive house principles, a high-performance building envelope, triple glazing, and a green roof.

HH Angus played a key role in this project, providing mechanical and electrical engineering services, as well as security, IMIT, lighting, AV, and plumbing design. The addition includes a new 25-metre, 6-lane pool, therapeutic pool, fitness centre, and common areas, for a total of 43,000 ft2 of added amenities.

Renovations to the existing community centre encompass improvements across 65,000 ft2, repurposing and relocating multi-purpose program spaces, gymnasium, indoor arena, and upgrading facilities to meet accessibility and green development standards. Despite challenges posed in connecting to the existing building, the addition was situated on the northeast corner, utilizing space from the adjacent park.

To see more renovations, click here

SERVICES

Mechanical Engineering | Electrical Engineering | Plumbing Design | Lighting Design | Audio-Visual Design | Security Design | IMIT Design

PROJECT FEATURES

Green facility design to LEED Silver standard | State-of-the-art aquatic centre | Equipment-based fitness centre | Status: Completed 2024

LOCATION

Mississauga, Ontario

KEY SCOPE ELEMENTS

Project built to Mississauga's Green Building standard | Achieved Level 1 CGBC | Addition connected to existing recreation centre | Renovations and upgrades to existing building

All images courtesy of CS&P Architects

Maple Leaf Sports and Entertainment

BMO Field ExpansionHH Angus and Associates provided mechanical and electrical consulting engineering for renovations to BMO Field. Home to the TFC, Toronto’s MLS football team, the existing facility quickly outgrew its amenities, a testament to the team’s popularity.

The BMO Field facility expansion featured: 8,400 additional seats, new washrooms and concession stands; 12 new executive suites; 2 party suites; a loge box; new full-service kitchen for restaurants, suites and clubs; 2 new private clubs (accommodating 230 / 420 patrons); expansion of the Rogers Club from 500 to 750 patrons, plus upgraded finishes and improved food, beverage and washroom facilities; a new, larger full HD video board; new loading dock; support spaces; and a new concourse at the south end of the stadium, creating one continuous concourse on the upper level. The project was drafted in REVIT, although it is not a true BIM project.

Some of the project challenges included coordination of the design package with the realities of site constraints and energy goals. HH Angus had dealt with these challenges in the past and had a depth of experience in Construction Management, P3, and Integrated Project Delivery methods, as well as having a firm grasp of the complexities associated with coordinating the design across multiple Revit models and with multiple firms.

The accelerated construction schedule presented a significant challenge. Work that traditionally occurs sequentially had to be delivered concurrently, which put pressure on the design team to accommodate not only increased coordination, but also a high number of changes from the original design intent.

One of the unique engineering considerations was the winterization of washrooms and concession areas. These areas are exposed directly to the elements during the winter and the facility management team did not want to drain the domestic system at the end of every season, as they had to do with the existing concourse areas.

SERVICES

Mechanical Engineering | Electrical Engineering | Energy Modeling | Lighting Design | Security and Communications Design

PROJECT FEATURES

Size: 150,700 ft2 | Status: Completed Phase 1 - 2015 & Phase 2 - 2016

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Renovation and expansion | Unique considerations included winterization of washrooms and concession areas to eliminate draining the domestic system at the end of each year

Queen’s University

Richardson Stadium Revitalization

HH Angus has a long and valuable relationship with Queen’s University, covering numerous projects across a range of buildings and services at the campus, including new build, renovations, expansions and district energy scopes of service.

In 2014, Queen’s began a revitalization of its premier sports facility, Richardson Stadium, and engaged HH Angus to provide mechanical and electrical engineering to the Revitalization project.

Our scope of work included mechanical and electrical design for the new East Building and renovated West Building; and electrical power design for the East and West Buildings, plus field lighting.

The Stadium work was executed in two phases: Phase One was the Feasibility Study and Phase Two covered the project implementation. To launch Phase One, system options and minimal requirements were confirmed with the University’s Facilities team in Kingston. There was also a series of meetings with the Construction Manager and primary trades to confirm the basis of the original estimates and to discuss the impact of system options.

Phase Two incorporated a value engineering exercise to develop alternative project phasing plans to maintain the budget. A final mechanical and electrical Schematic Design report was prepared following the value engineering exercise. Under Phase Two, HH Angus was retained to carry the project through from Design Development to Construction Administration.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2016

LOCATION

Kingston, Ontario

KEY SCOPE ELEMENTS

Electrical power design & field lighting for East and West buildings | Work executed in two phases, Feasibility Study (Phase 1) and Project Implementation (Phase 2)

Toronto Zoo

Wildlife Health Centre

The Toronto Zoo’s Wildlife Health Centre provides customized care for more than 5,000 animals, representing almost 500 species. HH Angus’ scope of work included the design of the new state-of-the-art animal hospital, laboratory services and research centre.

Special mechanical and electrical design considerations were required for design of the holding pens and keeper areas for a wide array of species, such as hoofed animals, strong mammals, amphibians, reptiles, avian, aquatic, etc. These considerations include lighting suitable for each species, specialized air distribution, and environmental controls.

The project included operating rooms and other animal treatment rooms built to meet or exceed current animal environmental standards for groups such as the Canadian Council on Animal Care (CCAC), the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) and the Association of Zoos and Aquariums (AZA).

Just as important were the spaces designed for the support laboratories, and the research laboratories specifically for animal conservation. The remainder of the building houses support spaces for nutritionists, veterinarians and researchers.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 34,000 ft2 | Status: Completed 2014

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Animal treatment rooms met or exceeded current animal environmental standards for CCAC, OMAFRA and AZA | Support laboratories | Research laboratories for animal conservation | Energy-efficient equipment for chiller and boilers

Complex phasing of services

During construction, the program required complex phasing of the mechanical and electrical systems, during which measures such as temporary air handling, re-routing of main communications cabling and heating lines were required. Existing systems were expanded to accommodate the complex demands of a modern animal hospital and research centre.

Specifying energy efficient equipment

Where new equipment was required, energy-efficient selections were specified, including magnetic bearing chillers, variable speed motors, and high efficiency condensing heating boilers.

Casino Rama

Power Infrastructure Upgrade

“The installation of protective electric equipment designed and specified by HH Angus is working amazingly, and has afforded us the confidence that we no longer need to pre-start all three of our 1 MW generators during every looming lightening storm”.

— John Haley, Director of Engineering and EVS Casino Rama

Casino Rama features over 2,500 state-of-the-art electronic gaming machines. The popular facility is owned by the Chippewa’s of Rama First Nation and the Ontario Lottery and Gaming Corporation. It welcomes over three million visitors annually.

Because power quality issues occasionally damaged sensitive electronics in gaming machines, Casino Rama gave HH Angus a mandate to find a solution that would protect equipment while minimizing games downtime, as well as shutdowns required to implement the solution.

HH Angus analyzed Casino Rama’s existing power distribution systems, critical loads, plans for future electrical load growth, and building infrastructure, including available service space and mechanical infrastructure.

A number of recommendations were presented, with varying degrees of risk mitigation and cost. Casino Rama opted for a 1.2 MW centralized uninterruptible power supply (UPS) for the portion of the existing emergency generator powered distribution system dedicated to their electronic gaming machines.

In addition to providing protection against power quality disturbances, the centralized UPS provides gamers with an uninterrupted playing experience during a utility power outage. The UPS bridges the gap between the onset of a utility power outage and the time it takes the onsite 3 MW emergency generators to come online and support the critical loads.

Implementing the centralized UPS system had its own unique challenges. Available service space had to be identified. The system had to be integrated with the facility’s electrical system in a way that minimized the time required for machine shut-downs and tie-ins. Additional air conditioning units were provided to ensure that the stipulated ambient temperatures were maintained. Structural reinforcement was also needed to ensure the floor slab could support the added weight of the battery banks. All these requirements had to be taken into account when designing the project.

SERVICES

Prime Consultant | Electrical Engineering

PROJECT FEATURES

Status: Completed 2012

LOCATION

Orillia, Ontario

KEY SCOPE ELEMENTS

1.2 MW central UPS dedicated to 2500+ gaming machines | Power distribution analysis | Integration with existing electrical system | Eliminated power quality issues

Zero Power Quality Issues

Since the installation of the centralized UPS system, Casino Rama has had no power quality incidents affecting their sensitive electronic gaming machines. In addition, electrical distribution fault-related downtime has been eliminated, resulting in a substantial reduction in annual maintenance costs.

Quote source: Casino Rama hires HHA to help with power infrastructure

— Photos courtesy of WZMH Architects