Service: Building Information Modeling

Confidential Client

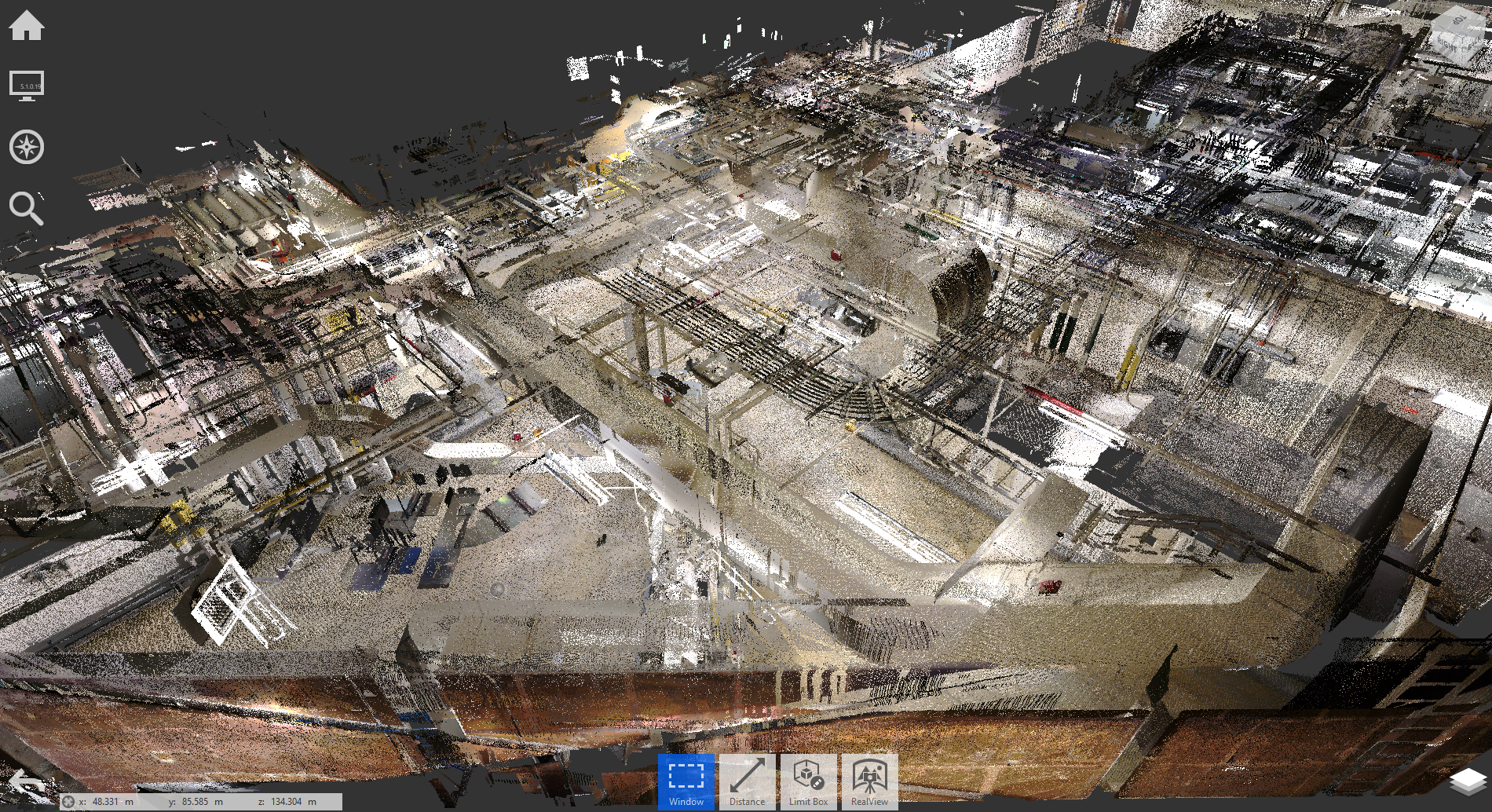

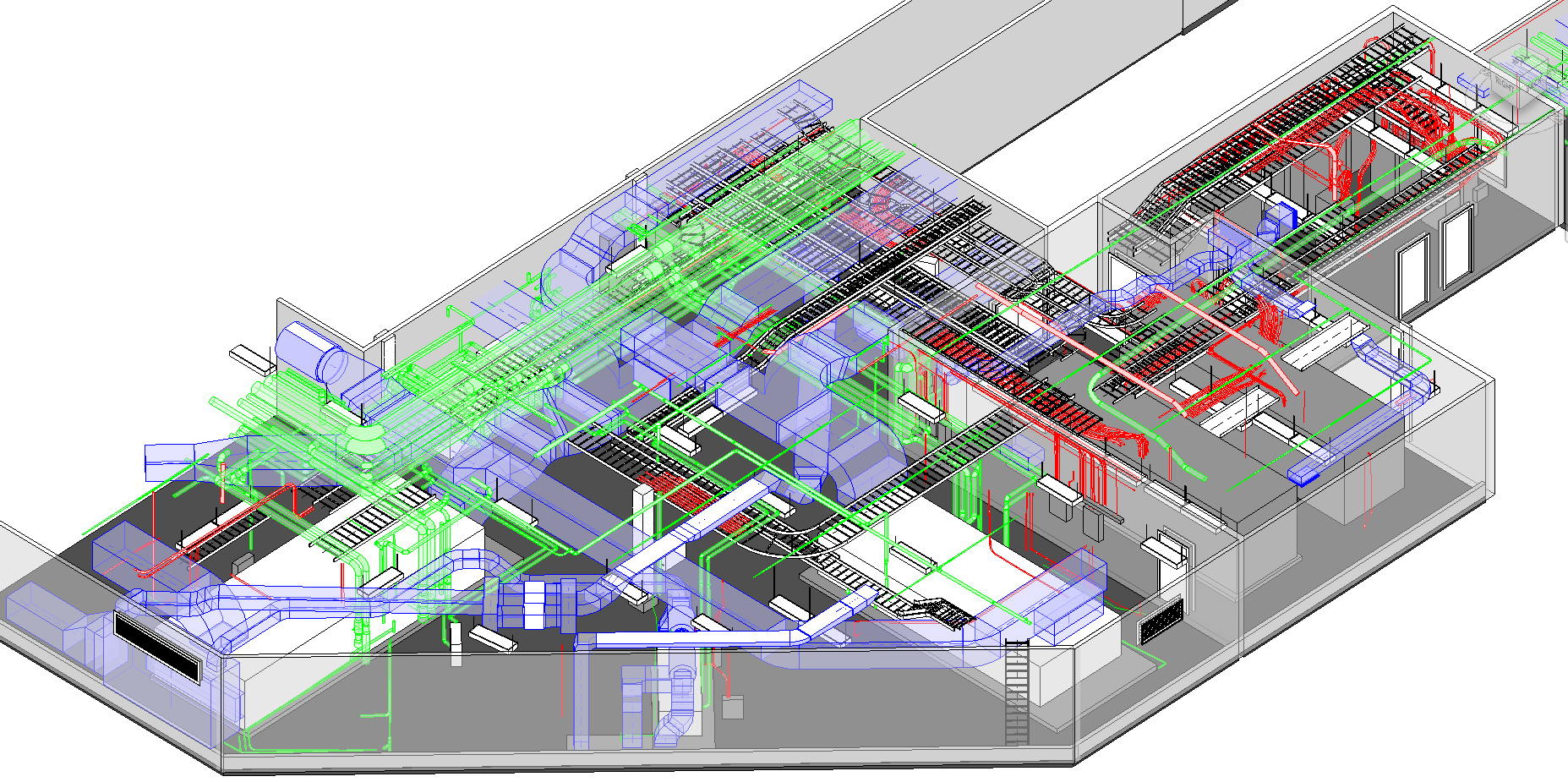

BIM Laser Scanning

HH Angus was engaged to create a 3D Revit model (LOD 300), accurate to reality, of the existing structure and visible HVAC, plumbing and electrical infrastructure. This model was delivered to the client for their use in 3D coordination of their high voltage switchgear replacement project.

The 17,000 ft2 area was scanned using a Faro S70 Laser scanner, with the scans subsequently registered using Faro Scene software to create point clouds. Point clouds were then processed in Edgewise modeling software and used to automatically extract and model walls, structure, piping, conduit and ducts, before being imported into Revit. This efficient process resulted in a very significant 60% reduction in modeling time. The remaining MEP infrastructure was modeled in Revit, with special attention paid to the location of the entry and leave points within rooms for all MEP infrastructure, in response to the client’s requirement.

One of the challenges of the project was the lack of easily accessible data required to create the Revit model. Recap pro or Faro Scene software is needed to review the point clouds and images; this software required licensing and installation on individual machines, which prevented it from being easily accessible to everyone on the project team. The software also requires additional computing power to run smoothly, and this presented an issue for machines that did not meet the software requirements.

SERVICES

Prime Consultant | Scan to BIM provider

PROJECT FEATURES

Revit modeling of existing structure and visible HVAC, plumbing and electrical infrastructure

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

3D laser scanning

Lower Mainland Facilities Management

Lions Gate Hospital Power Plant

The new underground power plant at Lions Gate Hospital is a key piece of infrastructure to enable construction of a new acute care facility in North Vancouver.

The existing steam-only power plant at Lions Gate Hospital did not meet seismic requirements and was quite dated. HH Angus replaced the existing plant with a new buried installation that includes boilers, medical gas, plumbing and electrical equipment, as well as the routing of services through an existing tunnel system.

The new design for the underground plant is a hybrid of hot water and steam boilers; this design will help to reduce both energy use and greenhouse gas emissions. It’s an innovative design that recovers heat from the power plant via a heat pump system and rejects heat back into the reheat systems. An architectural feature boiler stack was included in the design.

The RFP originally required relocation of the bulk O2 system; however, following a number of design iterations, the result was the provision of an Oxygen Concentrator system instead.

Implementation of the Fraser Health Authority’s BIM standards was also required for the project. This is the first time these standards were applied at HH Angus, and the work helped to develop a baseline for future Fraser Health projects.

Among the challenges of the project:

– With limited knowledge of the existing site, it was necessary to obtain all background information within a short timeframe through access to existing drawings (dating back to 1960s) and performing multiple site reviews.

– To provide the best solution, HH Angus explored multiple options, above and beyond the requirements of the original RFP and, although the timeline for completion of design and implemention of new BIM standards was aggressive, all deliverables were met on time.

SERVICES

Mechanical Engineering | Electrical Engineering | IMIT Consulting | Lighting Design

PROJECT FEATURES

Status: Completed 2020

LOCATION

North Vancouver, British Columbia

KEY SCOPE ELEMENTS

Power Plant to facilitate construction of new acute care facility | Architectural feature stack | 3D Matterport modeling | Oxygen concentrator system | Implementation of Fraser Health BIM Standards

3D Reality Capture

Our 3D Matterport scanner proved to be invaluable for site reviews, allowing the design team in Toronto to reference the minutely-detailed 3D scan produced by our in-house team and equipment.

Maple Leaf Sports and Entertainment

BMO Field ExpansionHH Angus and Associates provided mechanical and electrical consulting engineering for renovations to BMO Field. Home to the TFC, Toronto’s MLS football team, the existing facility quickly outgrew its amenities, a testament to the team’s popularity.

The BMO Field facility expansion featured: 8,400 additional seats, new washrooms and concession stands; 12 new executive suites; 2 party suites; a loge box; new full-service kitchen for restaurants, suites and clubs; 2 new private clubs (accommodating 230 / 420 patrons); expansion of the Rogers Club from 500 to 750 patrons, plus upgraded finishes and improved food, beverage and washroom facilities; a new, larger full HD video board; new loading dock; support spaces; and a new concourse at the south end of the stadium, creating one continuous concourse on the upper level. The project was drafted in REVIT, although it is not a true BIM project.

Some of the project challenges included coordination of the design package with the realities of site constraints and energy goals. HH Angus had dealt with these challenges in the past and had a depth of experience in Construction Management, P3, and Integrated Project Delivery methods, as well as having a firm grasp of the complexities associated with coordinating the design across multiple Revit models and with multiple firms.

The accelerated construction schedule presented a significant challenge. Work that traditionally occurs sequentially had to be delivered concurrently, which put pressure on the design team to accommodate not only increased coordination, but also a high number of changes from the original design intent.

One of the unique engineering considerations was the winterization of washrooms and concession areas. These areas are exposed directly to the elements during the winter and the facility management team did not want to drain the domestic system at the end of every season, as they had to do with the existing concourse areas.

SERVICES

Mechanical Engineering | Electrical Engineering | Energy Modeling | Lighting Design | Security and Communications Design

PROJECT FEATURES

Size: 150,700 ft2 | Status: Completed Phase 1 - 2015 & Phase 2 - 2016

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Renovation and expansion | Unique considerations included winterization of washrooms and concession areas to eliminate draining the domestic system at the end of each year

Confidential Client

Data Centre Expansion

Data centres operate 24/7. This large Tier 3 facility expansion required defined levels of redundancy to ensure the most complete reliability possible.

Our mechanical and electrical design included a central cooling plant and emergency generation system to support the critical data floors. The development involved a two-phase ‘design and construct’ concept, which was incorporated into the base design and operating strategy. The project was executed on time and within budget.

Mechanical Design

The Phase 1 concept required 3 X 750 ton centrifugal chillers, electrically powered with variable frequency drives (VFD’s) and incorporating N+1 redundancy. The chilled water distribution system was based on a primary and secondary concept with a ring main for increased redundancy, which allowed for back feeding in the event of hardware failure. All pumps have VFD’s for slow start and energy efficiency. Transformers were used to step down from 600V to 460V to further increase reliability on the VFD’s. The condenser water system was based on induced draft with counter flow cooling towers with VFD’s on the fans and utilizing tower free cooling for energy efficiency.

The design of the cooling system provided for Phase 2 expansion and the ability to implement an additional 2250 tons of cooling through 3 X 750 ton chillers, with improved redundancy to (N+2). The mechanical piping and ventilation design was carried out using Bentleys Autoplant 3D software to ensure functionality of the equipment and piping layout design. The 3D modeling was used successfully by the Constructor and integrated into their BIM (Building Information Modeling) program.

Electrical Design

The electrical engineering design provided for a 50,000 ft2 raised floor computer area serviced by redundant feeds from the existing 27.6kV distribution to redundant 600V distribution systems. Four 2 MW parallel synchronized diesel generators with capacity to increase to six; two systems of four redundant 750 kVA UPS modules; and state-of-the-art life safety, alarm monitoring, and security systems.

Subsequent upgrades to the facility included installation of two 3000A Static switches to the two parallel redundant 750kVA UPS systems, configured to not only permit seamless transfer of critical loads between utility and emergency power in the event one UPS system fails, but also to permit seamless transfer to the surviving UPS system. HH Angus functioned as Prime Consultant and Electrical Engineer for a series of reports, studies, distribution upgrades and raised floor expansions at the site.

The Data Centre’s diesel generator system included three buried storage tanks, each with a capacity of 75,000 litres, a generator ventilation system and diesel exhaust for four 2MW generators.

ICT Scope

Our communications group was involved with multiple communications projects for the expansion, starting from the structured cabling system, DAS –Distributed Antenna System, and building systems LAN/WLAN design. We provided a detail compliance analysis of the new proposed sites with references to the TIA 942 Data Centre standard.

As a part of the DAS, we provided an unbiased, independent assessment of the current data centre cabling infrastructure performance, as well as design recommendations and specifications to eliminate both scheduled and unscheduled downtime. The assessment included a comprehensive computer room site inspection, determination of the full scope of the telecommunications needs, design of a suitable structured cabling system, and the creation of written reports, prints and specification documents.

SERVICES

Mechanical Engineering | Electrical Engineering | Communications Design

PROJECT FEATURES

Status: Completed 2010

KEY SCOPE ELEMENTS

Comprehensive assessment of existing IT infrastructure | Engineering for structured cabling systems, DAS and building LAN/WLAN design | Identified full scope of telecommunication requirements | N+1 redundancy | 3 X 750 ton centrifugal chillers powered by VFD's | Multiple communications projects

Designing for Uptime

Reliability was improved with underground remote water storage to support a 24-hour cooling tower make up in the event of supply water failure.

Electrical reliability was achieved through the installation of 6 X 2 MW diesel generators (N+1 redundancy), and a fuel storage facility consisting of 3 X 75,000L underground tanks.