Service: Mechanical Engineering

Enwave Energy Corporation

Pearl Street Cogeneration Plant

HH Angus provided design and engineering services for Enwave’s CHPSOP 2.0 contract to install a 2 x 2 MW Cogen project at the Pearl Street plant.

The Pearl Street steam plant is one of two major boiler plants that service Enwave’s downtown Toronto heating system, and usable plant space there was a significant constraint. The new cogeneration was to be installed in limited space in the basement.

We first undertook a feasibility study to determine whether the existing basement would accommodate a 4 MW single engine or 2 x 2 MW engines. Based on the study results, Enwave selected the 2 x 2MW option.

The initial phase of the detailed design was to determine which cogeneration engines would be options, given the space constraints. It was established that only one supplier’s equipment would fit. The next phase involved pre-tenders, including engine generator sets, heat recovery steam generator, selective catalytic reduction, and switch gear.

Plant design used 3D software to ensure all equipment could fit without coordination clashes. The combustion and ventilation required were a major challenge, entailing architectural changes to the building to meet code, and a new area way on the outside of the building, to allow for combustion air and ventilation air. The engine generator had to be disassembled at the distributor and reassembled on site. The focus then moved on to locating a suitable routing for the breeching and silencers off the engine exhausts, which had to travel from the basement to the roof.

In a CHPSOP 2 contract, the client is exporting power into local LDC (Toronto Hydro). HH Angus designed protection, monitoring, and control requirements per Toronto Hydro’s embedded generation technical interconnection requirements.

HH Angus coordinated with Toronto Hydro, on behalf of the client, for: revenue metering CTs/PTs to install in the switchgear hydro compartment; metering cabinet; and commissioning of the synchronization test, protection, and SCADA points. We also issued a signed, embedded generation commissioning report.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Use of 3D plant design to ensure all equipment could be accommodated | Design restricted by space constraints | Design, protection, monitoring & control requirements per Toronto Hydro's embedded generation technical interconnection requirements

Confidential Client

Deodorizer Installation

HH Angus served as prime consultant for this new deodorizer processing plant. The new installation more than doubled the oil refining facility’s existing capacity.

Palm oil is the most widely-used edible oil in the world. Deodorizing is the final stage in refining the oil, and is required to remove odoriferous material, free fatty acids and other undesirable minor components, in order to produce a bland oil with a good shelf life.

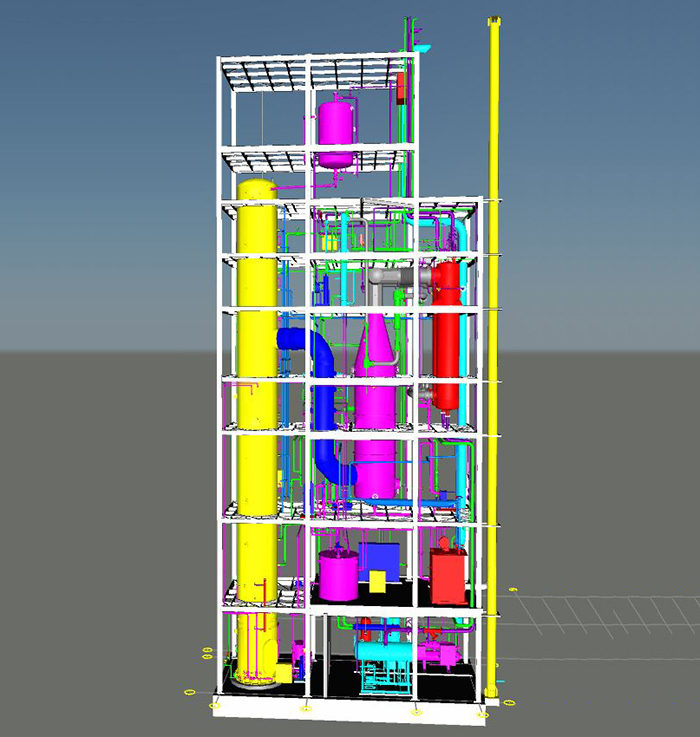

The deodorizer tower is 30m high and 2m in diameter, with connected boilers, pumps, etc., that required connection to the existing production plant located adjacent to the expansion area. Due to the height and sectioning of the deodorizer, it had to be built in two stages.

One of the key challenges of the project was the site constraints. Two feasibility studies were produced as part of the investigation. It was determined that a new building was needed, rather than trying to install the deodorizer in the existing building.

In order to accommodate the electrical needs of the deodorizer process, a system upgrade was required to the switchgear. The upgrade allows the client the flexibility to install other major equipment in future.

Enabling projects for the deodorizer installation included a nitrogen tank installation, cooling water system, a new natural gas let down station, and new gas feed to the site.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

KEY SCOPE ELEMENTS

Detailed Engineering Study | 3D modeling | 30m high deodorizer tower connected to existing plant within site constraints | Nitrogen tank installed | System upgrade to switchgear provided flexibility to install other major equipment in future

Modeling in 3D

As a special feature of the project, HH Angus modeled the installation using Plant 3D software. The installation was quite complex, and creating the model reduced both design time and the construction schedule. The contractor was able to see a comprehensive view of the design, confirming locations of pipes, etc.

McMaster University

Trigeneration Plant

HH Angus was initially engaged to perform a Detailed Engineering Study to determine the viability of installing a natural gas-fired turbine for power and steam generation, and the use of absorption cooling to balance out steam production in the warmer months.

For a full year, we reviewed heating, cooling and electrical power loading at McMaster University. We also reviewed operating costs covering maintenance, operating and natural gas costs, and completed a sensitivity analysis of gas and power pricing variances. Capital and Operating budgets were also prepared to determine ROI on the proposed investment.

Following the Detailed Engineering Study, we were engaged to design the new trigeneration plant using a gas turbine (5.4 MW) coupled with an HRSG (Heat Recovery Steam Generator), natural gas compressor, absorption chiller (1000 tons) and centrifugal chiller (2500 tons). The plant was installed in the existing central utility plant room, and significant demolition of redundant equipment was undertaken to generate the space for this system upgrade.

There were a number of interesting challenges associated with the work:

- Selective demolition of two existing steam boilers, two existing incinerators and one 5,000 ton electric centrifugal chiller including isolation of services and asbestos abatement to not impact existing plant operations

- Fitting this large equipment into an area with significant space constraints

- Creating a path of ingress for the equipment from outside into the sub-grade basement level of the plant for installation during winter months where the weather would be unpredictable

- Minimizing the impact on daily operations within the plant during the demolition and construction phases.

- Integration and coordination with a switchgear replacement project running in parallel with the cogeneration project

- Targeting a completion date of October, 2017 to ensure the client would receive full IESO funding for the project

Some of our solutions included:

- Thorough surveys of existing equipment and services to ensure the equipment slated for demolition could be isolated from the operating plant with minimal to no service interruption

- Engaging with equipment suppliers at an early date to ensure required footprints were allocated

- Coordinating with the structural engineers to design a removable roof cap that could be installed prior to the existing roof being cut open to allow equipment installation

- On-going coordination with plant staff during the design phase to get buy-in of any modifications required to the existing plant

- Pre-tendering long lead item equipment to ensure on-site delivery dates would meet the construction schedule

By designing to eliminate potential interferences or issues with installation, we were able to meet the delivery targets and deliver a successful project.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

LOCATION

Hamilton, Ontario

KEY SCOPE ELEMENTS

Year-long detailed engineering study | Reviewed heating, cooling and electrical power loading | Study included sensitive analysis of gas and power pricing variances | Introduced new design for trigeneration plant usage, a gas turbine (5.4MW) coupled with an HRSG, natural gas compressor, absorbtion chiller and centrifugal chiller

Durham Region Transit

Oshawa Bus Maintenance Facility

Durham Region needed to accommodate the repair/maintenance requirements of its fleet of buses with a facility that would be integrated into an existing building. The project is on track for LEED® Silver Certification.

The project features a state-of-the-art Transit Control Centre on the second floor for regional bus and GTAA connection communications. Highlights include state-of-the-art ventilation and exhaust systems, fuel/fluid dispensing, a vacuum cleaning system, parts dispensing, tire storage/ servicing, lubrication stations, paint booths and a bus wash station. The mechanical design scope included plumbing, fire protection, HVAC, controls and process systems and services. The building was designed to reduce energy and water demand and includes for rainwater storage facilities.

The electrical scope included normal and emergency power systems, fire alarm, state-of-the-art LED lighting and integrated IT System (incorporating time management, clock system, Presto system, communication systems and various radio systems). Durham Region building standards also required design of a lightning protection scheme.

SERVICES

Mechanical Engineering | Electrical Engineering | IT | Security and Communications Design | Lighting Design

PROJECT FEATURES

Size: 60,000 ft2 - 5500 m2 | Status: Completed 2016

LOCATION

Oshawa, Ontario

KEY SCOPE ELEMENTS

State of the art ventilation and exhaust | Controls & process systems and services | Additional design for lighting protection scheme | Energy use reduction strategies | Rainwater storage | Designed to achieve LEED Silver

Queen’s University

Richardson Stadium Revitalization

HH Angus has a long and valuable relationship with Queen’s University, covering numerous projects across a range of buildings and services at the campus, including new build, renovations, expansions and district energy scopes of service.

In 2014, Queen’s began a revitalization of its premier sports facility, Richardson Stadium, and engaged HH Angus to provide mechanical and electrical engineering to the Revitalization project.

Our scope of work included mechanical and electrical design for the new East Building and renovated West Building; and electrical power design for the East and West Buildings, plus field lighting.

The Stadium work was executed in two phases: Phase One was the Feasibility Study and Phase Two covered the project implementation. To launch Phase One, system options and minimal requirements were confirmed with the University’s Facilities team in Kingston. There was also a series of meetings with the Construction Manager and primary trades to confirm the basis of the original estimates and to discuss the impact of system options.

Phase Two incorporated a value engineering exercise to develop alternative project phasing plans to maintain the budget. A final mechanical and electrical Schematic Design report was prepared following the value engineering exercise. Under Phase Two, HH Angus was retained to carry the project through from Design Development to Construction Administration.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2016

LOCATION

Kingston, Ontario

KEY SCOPE ELEMENTS

Electrical power design & field lighting for East and West buildings | Work executed in two phases, Feasibility Study (Phase 1) and Project Implementation (Phase 2)