Service: Mechanical Engineering

The McEwan Group

Fabbrica TD

Fabbrica's second location was designed as a take-out venue. The 4200 ft2 retail space is accessed via Toronto's underground PATH system, in the heart of the city's financial district. Fabbrica on the PATH joins its sister outlet across the hall, the McEwan grocery store.

HH Angus was engaged to provide mechanical, electrical and lighting design services for the tenant fitout of the new Fabbrica on the concourse level of the TD Centre. Fabbrica took over an existing space which required ceiling demolition in order to install new lighting and electrical systems.

Custom interior lighting was designed to attract the attention of commuters and shoppers in the PATH system. To achieve this, 3500K 12W high-colour-rendering LEDs were incorporated into the lighting design to showcase the vibrant colours of the meal offerings prepared for hungry consumers.

The project's location in the concourse level posed a design challenge to the team, due to the modest amount of ceiling and underfloor clearance. To accommodate these restrictions, HH Angus designed solutions to manage the routing of piping, conduits and drainage within the limited space.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 4,200 ft2 | Status: Completed 2018

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Limited space above and below the retail space required innovative design approaches | High Colour Rendering LEDs

Confined spaces

The space restrictions of the site, with regard to M&E infrastructure, required extensive site surveys, plus special attention being paid to obstructions in the parking levels below.

Toronto Transit Commission

Waterfront East LRT - Union Station and Queens Quay Link

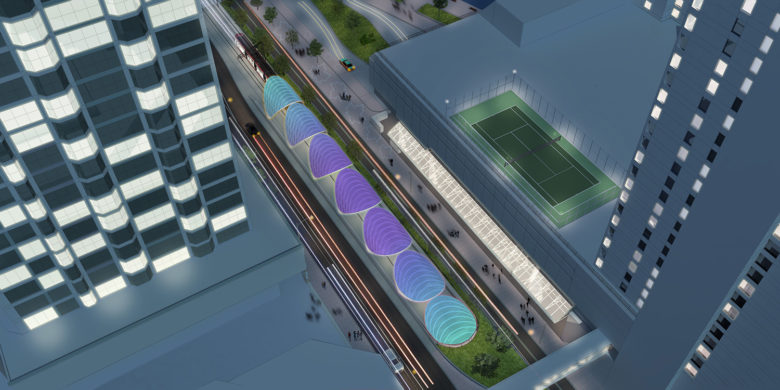

The existing streetcar service begins underground at Union Station, extends south under Bay Street towards Queens Quay Station, and continues west under Queens Quay before surfacing at the portal just west of Harbour Square. The expansion will include for a new portal on Queens Quay West, between Bay and Yonge Streets, to allow for service expansion eastward along the surface of Queens Quay West.

HH Angus was engaged to provide mechanical and electrical consulting services for Preliminary Design Engineering for the Waterfront East LRT project. The work includes a Baseline Design (~ 30% design completion), a Class 3 AACE Construction Cost Estimate, and Level 3 project delivery schedule. This is to accommodate the growth and future passenger volume as part of Toronto’s waterfront revitalization project for the expansion of the existing Union and Queens Quay LRT Stations, and a new running tunnel and portal.

The upgrade will expand on the single track Union Streetcar Loop with a split unloading and boarding platform to become a side-platform station, with each platform capable of accommodating two vehicles simultaneously. An additional by-pass track with special trackwork on the outside of the passenger boarding/unloading track will also be accommodated within the station.

The existing side platform at the Queens Quay station will also be upgraded to accommodate two vehicles simultaneously boarding/unloading at each platform. In addition, the station will provide access to the Jack Layton Ferry Terminal and Toronto’s downtown underground PATH network.

The tunnel ventilation solution—providing at-grade ventilation shafts within a land-locked congested downtown area—required a thorough understanding of various design criteria, as well as meticulous coordination with Architectural, Structural and Civil Utilities disciplines. The final design would entail further computational design analysis beyond the scope of this project in order to address a design variance.

For the overhead catenary system, the team drew on involvement with previous projects (where we were not the designer of said system) to adapt and provide a tailored solution for the unique project requirement of traction power delivery within stations, tunnels, portals, above-grade and transitions in between, working closely with Civil Trackway and Structural disciplines.

SERVICES

Mechanical Engineering | Electrical Engineering | Plumbing Design | Security & Communications Design | Vertical Transportation Consulting

PROJECT FEATURES

Upgraded and expanded LRT | Status: 30% design completed

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Waterfront revitalization project | Baseline Design (~ 30% design completion) | Class 3 AACE Construction Cost Estimate | Level 3 project delivery schedule

*Renderings courtesy of Strasman Architects Inc.

Innisfil Health Partners

Rizzardo Health & Wellness Centre

“[This is] a building designed with an aim of having the highest health standards, engaging the community, and being flexible to meet changing needs.” *

The community health hub, an outreach of Royal Victoria Hospital (RVH) in Barrie, serves the towns of Innisfil and northern Bradford/West Gwillimbury. Among its many offerings are blood services, pharmacy, walk-in clinic, radiology, dental clinic, café/community kitchen, interactive kitchen, doctors’ offices, mental health services, physiotherapy, etc. HH Angus provided M&E and ICAT services to the base building and site, along with full tenant fitout.

SERVICES

Mechanical engineering | Electrical engineering | Lighting Design | IMIT consultant | AV, communications, security design

PROJECT FEATURES

Size: 41,000 ft2 | Status: Completed 2019

LOCATION

Innisfil, Ontario

KEY SCOPE ELEMENTS

Multiple healthcare and community

services | Double high atrium, full glass

walls | Flexible design to allow adaptive use to meet community needs

Flexible design

The Rizzardo Health Centre was designed with flexibility in mind, to allow its services and spaces to adapt to evolving community care needs.

Protecting client interests

One of the challenges of this project was a change in procurement method during the execution of the work, from stipulated sum to design build. Part of our value to the client in this situation was in protecting them from added costs.

*Bradford Today, Miriam King, March 21, 2019

Lower Mainland Facilities Management

Lions Gate Hospital Power Plant

The new underground power plant at Lions Gate Hospital is a key piece of infrastructure to enable construction of a new acute care facility in North Vancouver.

The existing steam-only power plant at Lions Gate Hospital did not meet seismic requirements and was quite dated. HH Angus replaced the existing plant with a new buried installation that includes boilers, medical gas, plumbing and electrical equipment, as well as the routing of services through an existing tunnel system.

The new design for the underground plant is a hybrid of hot water and steam boilers; this design will help to reduce both energy use and greenhouse gas emissions. It’s an innovative design that recovers heat from the power plant via a heat pump system and rejects heat back into the reheat systems. An architectural feature boiler stack was included in the design.

The RFP originally required relocation of the bulk O2 system; however, following a number of design iterations, the result was the provision of an Oxygen Concentrator system instead.

Implementation of the Fraser Health Authority’s BIM standards was also required for the project. This is the first time these standards were applied at HH Angus, and the work helped to develop a baseline for future Fraser Health projects.

Among the challenges of the project:

– With limited knowledge of the existing site, it was necessary to obtain all background information within a short timeframe through access to existing drawings (dating back to 1960s) and performing multiple site reviews.

– To provide the best solution, HH Angus explored multiple options, above and beyond the requirements of the original RFP and, although the timeline for completion of design and implemention of new BIM standards was aggressive, all deliverables were met on time.

SERVICES

Mechanical Engineering | Electrical Engineering | IMIT Consulting | Lighting Design

PROJECT FEATURES

Status: Completed 2020

LOCATION

North Vancouver, British Columbia

KEY SCOPE ELEMENTS

Power Plant to facilitate construction of new acute care facility | Architectural feature stack | 3D Matterport modeling | Oxygen concentrator system | Implementation of Fraser Health BIM Standards

3D Reality Capture

Our 3D Matterport scanner proved to be invaluable for site reviews, allowing the design team in Toronto to reference the minutely-detailed 3D scan produced by our in-house team and equipment.

Oshawa Clinic Group

West Whitby Medical Clinic

The Oshawa Clinic Group is developing a new healthcare facility in response to the need for a large integrated medical office building to support the growing population of Durham Region.

HH Angus is providing M&E consulting services for this 120,000 ft2 clinic. The building is 4-storeys plus a basement fitout. When complete, the building will include primary care physicians’ offices and exam rooms, an urgent care walk-in clinic, and a range of specialist clinicians, including an audiology and hearing aid clinic, a chest pain clinic, chiropractors, dentists, diagnostic imaging, medical supply sales, a retail pharmacy with a compounding area, physiotherapy clinic, and a sleep study clinic with nine beds.

Additional patient services include:

- eye wear sales

- home respiratory equipment sales and services

- phlebotomy and medical test laboratories

- sterilization area, and

- traditional Chinese medicine clinic.

The project was featured in Canadian Healthcare Technology in July 2021.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: 120,000 ft2 | Status: Completion 2024

LOCATION

Whitby, Ontario

KEY SCOPE ELEMENTS

Purpose-built clinic | 4 storeys plus basement fitout | Primary care physician offices, urgent care walk-clinic | multiple specialized labs and clinics

Customized design

The project is a purpose-built building in Whitby Ontario.