Service: Mechanical Engineering

Sunnybrook Health Sciences Centre

Garry Hurvitz Brain Sciences Centre

“The Garry Hurvitz Brain Sciences Centre will revolutionize the future of brain health like never before. It will be a global hub of innovation that will accelerate the discovery of the next generation of treatments, prevention and possible cures to the world’s most debilitating brain conditions.”*

HH Angus is providing mechanical and Electrical engineering for this 118,285 ft2, three-storey above-grade structure. The building will be constructed within a dense urban campus between existing building wings and will be connected to the main hospital circulation spine, with flexibility provided to accommodate future expansion.

Our project scope includes:

- Expansions to existing infrastructure, including a new 1600 ton centrifugal 4160 volt Chiller;

- A major modification to the Emergency Power System to provide emergency power to at least one chiller and the chilled water distribution system;

- New steam service and high voltage electrical services to the new building from the existing power plant

- A significant Information Technology service and distribution system, including fibre cable connections to the hospital’s existing Core Distribution Rooms, new network hub room components, including network switches and all on-floor cable/outlet systems

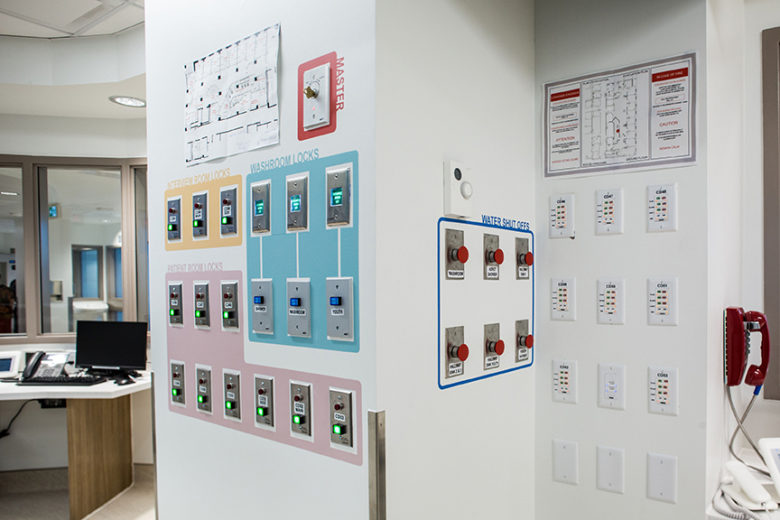

- Significant expansions to the existing Building Automation System, central electrical metering system, fire alarm system, security system, CCTV system, nurse call system and Code White systems.

The new building includes:

- Mechanical and electrical services in the basement designed to provide for the current construction, as well as a possible future four-storey addition

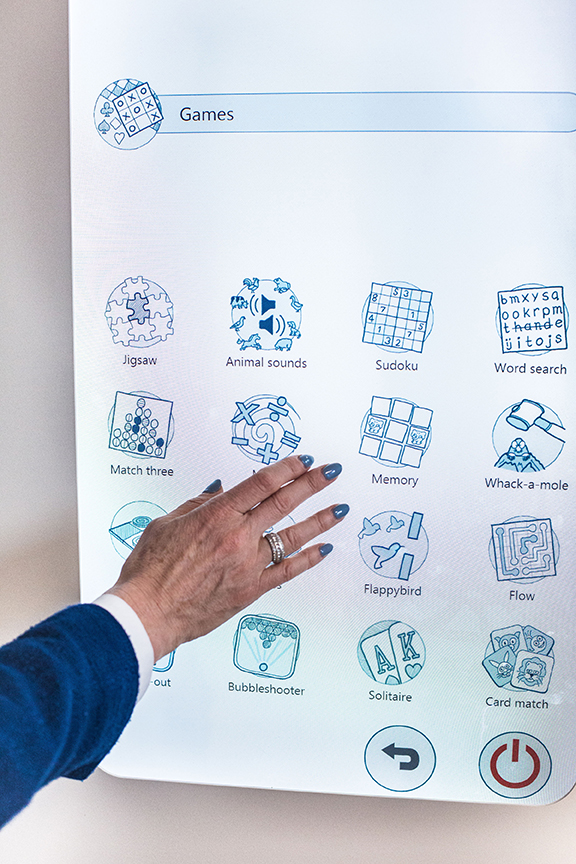

- Adult In-Patient Mental Health Unit and PICU Unit on the ground floor, both with access to outdoor courtyards

- Child & Youth Mental Health Unit

- Circadian Study Unit on 1st Floor

- Neuromodulation Treatment Unit, Enhanced Examination, Teaching and Research units on the 2nd Floor

The Sunnybrook M&E services tunnel is a complicated space. Because this is a new building on an existing site and represents a major expansion to the campus, connections to existing buildings with multiple M&E ties are required.

Among the interesting challenges of this project was obtaining the required mechanical and electrical services spaces. The larger they became, the more they impacted the functional programming and the project budget. Compromises were made regarding ceiling heights, and collaboration with facilities management staff helped in obtaining the space required.

As well, the main entrance “glass box” presented some unique mechanical design challenges. Ventilating a two-storey structure with no exposed services required innovative engineering, including ventilating from below.

In designing the building systems for this project, our team devoted special attention to providing a living space that offers an excellent therapeutic environment for the brain-injured patient while, at the same time, ensuring the safety of both patients and staff; in particular, preventing any opportunity for self-harm by patients.

Within HH Angus’ lighting scope, LED linear fixtures set the stage for modern lighting aesthetics used throughout the new, state-of-the-art centre, including corridors, inpatient bedrooms, the main triple height lobby, and the exterior soffits. The efficient LED non-glare, dimmable lighting will be connected to a centralized lighting control system. The provided lighting management software enables facility managers to monitor, maintain and control the entire networked lighting control system, including schedules and energy usage.

SERVICES

Mechanical Engineering | Electrical Engineering | Plumbing | Lighting Design | Audio-Visual Design | Communications Design | Condition Assessment | Feasibility Study

PROJECT FEATURES

Size: 118,285 ft2 | Status: Ongoing | Adult In-Patient Mental Health Unit | PICU Unit | Child and Youth Mental Health Unit | Circadian Study Unit | Neuromodulation Treatment Unit | Complex M&E services tunnel

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Expansion to existing infrastructure | Major modification to Emergency Power System | New steam service and high voltage electrical services | Significant IT service and distribution system | Expansion to numerous systems, including BAS, electrical metering, fire alarm, security, CCTV, nurse call and Code White

Innovative engineering

The main entrance “glass box” presented some interesting mechanical design challenges. Ventilating a two-storey structure with no exposed services required innovative engineering, including ventilating from below.

Experience counts

HH Angus’ many years of working on the Sunnybrook campus and our familiarity with this particular space aided significantly in designing the connections to the existing services.

The Co-operators Canada

Tenant Fitout

“Our people will have first class work environments that support their wellbeing and set the bar in our industry when it comes to workplace design and sustainable construction.”

Shawn Fitzgerald, VP Enterprise Procurement/Workplace Services, The Co-operators

HH Angus designed a complete fitout, including mechanical, electrical, ICAT, and emergency backup power design for this 9-storey renovation. Each floor was a mix of open office and collaboration spaces with ancillary serveries. The second floor had a full commercial kitchen and café area.

Among the challenges of the project was the existing building back up power system, which was not configured to support the new equipment our client desired. We worked closely with our client’s landlord and building managers to find a solution that provided the client with the ability to operate 24/7 without overloading the existing system’s capabilities. Through careful calculations and creative thinking, we were able to reconfigure the existing MCC (motor control centre), and transfer the most crucial items onto the generator system.

Our team worked closely with the return-to-base engineers to relocate new infrastructure within their project scope, in order to ensure work did not need to be duplicated later in our scope. A good example of this was collaborating on new heat pump locations. Since many locations on the floor plates have exposed ceilings, we ensured heat pumps were being located optimally during the back-to-base work, removing the requirement for our project to move them.

When the COVID-19 epidemic became a factor in the late stages of the project, our team quickly adapted to ensure trades were kept accountable and on schedule for project delivery.

SERVICES

Mechanical Engineering | Electrical Engineering | ICAT Design | Audio-Visual Design | Communications Design

PROJECT FEATURES

Status: Completed 2020 | 9 storey complete fitout | Each floor a mix of open office and collaboration spaces | Ancillary services – full commercial kitchen and café

LOCATION

Regina, Saskatchewan

KEY SCOPE ELEMENTS

9 storeys | Equipment retrofit for existing emergency power system | Detailed coordination with interior design team for multiple ceiling arrangements | Participated in value engineering discussion to meet client’s needs within available budget

St. Joseph’s Health Centre

Mental Health Emergency Services UnitWe consulted with hospital clinical staff, the architect and best practices documentation in the field of Mental Health design in order to provide tamper-proof and anti-ligature versions of M&E devices and services in all patient rooms.

Our project scope was the complete redevelopment of the existing Mental Health Emergency Services Unit. This involved upgrading and modernizing the unit in order to support eight patient rooms, (the previous unit had only three patient rooms).

New, energy-efficient LED lighting fixtures, complete with dimming controls, replaced the old, inefficient fluorescent lighting fixtures. Remote patient room controls, located at the Nurses’ Station, allow clinical staff to control the electrical receptacle in each patient’s room, the smart glass on the room’s door/window, as well as the room’s lighting fixture, including remote-controlled dimming. A modern real-time locating system was also provided; it includes patient tracking, staff duress and patient wandering functionality. Note: This project was honoured with a 2020 Toronto IES Illumination Section Award

More than 30 IP-based security cameras were installed, including two cameras in each patient room. These are viewable from computers at the Nurses’ Station.

One of the challenges of the project was that the hospital did not have a viable existing IT room to house all the new voice/data infrastructure. As a result, we had to design a new IT room on the floor below the renovation area to support the new unit and future Emergency Department redevelopment. This was done during construction; therefore, the design and coordination were fast-tracked and subsequently completed successfully.

Also, remote patient room controls were not well defined throughout the design process. During construction, we had to quickly coordinate with several vendors, each with a proprietary system, in order to provide a solution that the contractor could execute.

SERVICES

Mechanical Engineering | Electrical Engineering | Communications and Security Design | Lighting Design

PROJECT FEATURES

Status: Completed 2019 | Winner: 2020 Toronto IES Illumination Section Award | Energy-efficient LED lighting | Remote room controls | Real-time locating service | 30 IP-based cameras | New IT room

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Tamper-proof and anti-ligature M&E services | Design of remote room controls to provide enhanced staff safety and minimizing disturbance to patients | Fast-track design of IT room was required during construction stage

Remotely located controls

This approach provides increased staff security and convenience, and minimizes disturbance to patients.

Optimal visibility

A new security and communications design allows safe observation of patient activities from a secure staff area.

Ontario Ministry of Health

Ontario Agency for Health Protection & Promotion (OAHPP)

(Sheila Basrur Centre)

Following the 2003 SARS outbreak, Public Health Ontario needed a site to bring together academic, clinical, public health and government experts on infection control and prevention. HH Angus was instrumental in providing a high quality, energy-saving workplace to meet LEED-CI Silver standards, key to highlighting PHO's commitment to sustainable practices.

A new 250kW natural gas-fired generator installed on the roof is the heart of the command centre. Its purpose is to exclusively back up the Electrical and Supplemental HVAC systems serving the command centre. As the area has unusual 416/240V service, special voltage requirements were engineered to facilitate both lighting and power equipment. Harmonic-type transformers provided clean, non-distorted power to two distribution panels, 80KVA UPS, receptacle, lighting panels and HVAC units. The 80KVA UPS unit provides 30 minutes of non-interrupted power to the command centre to allow the generator to start and reach full load capacity.

Since the original building did not meet LEED HVAC requirements, we provided detailed and well-thought-out designs to meet LEED criteria. High efficiency fixtures reduced the burden on city water supply and waste water systems. In addition, lighting was a major component for the LEED-CI Silver criteria, with glare and contrast ratio control, linear fluorescent direct/indirect lighting systems, LED downlights, and daylight harvesting.

Information technology infrastructure was key to the successful long-term functioning of this facility. The infrastructure included telecommunications rooms, conduits, cable support systems and structured cabling systems. The IT rooms house all of the building’s telecommunications fiber optics and copper backbone systems, horizontal cabling system and networking equipment, including telephone, data and video services. In the meeting spaces, the large display wall is intended for daily presentation requirements but, in the case of an emergency response scenario, the room will serve as a 24x7 mission critical war room.

SERVICES

Mechanical Engineering | Electrical Engineering | Communications Design | Lighting Design

PROJECT FEATURES

Status: Completed 2009 | 40,000 ft2 | 250kW natural gas generator for emergency back up power | 416/240 volt service required special engineering for lighting and power | 80 KVA UPS

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

250kW natural gas-fired generator | Achieving LEED requirements, particularly for HVAC and Lighting | IT infrastructure

Seneca College of Applied Arts and Technology

Garriock Hall Mechanical Retrofit

Located on the King City campus, Garriock Hall renovations are part of Seneca’s on-going expansion. The retrofitted heating system provides improved comfort for the campus’ 5,200 students.

HH Angus was engaged as prime consultant for a retrofit at one of the campus’ main academic buildings. Our scope included replacement and upgrade to:

- Twelve fan coil units, complete with additional coil elements

- Approximately 30 hot water cabinet unit heaters located throughout the building, along with additional Building Automation System (BAS) integration

- Dual-duct terminal boxes for approximately 2/3’s of the building. The terminal boxes themselves were upgraded from pneumatically controlled to digital controlled complete with BAS integration.

- Domestic hot water system

- Pool heating system

The project used low temperature heating water from a ground-source heat pump system. This increased the physical size of the replacement heaters, which required accompanying structural and architectural modifications.

Domestic hot water preheat was implemented to take advantage of the low temperature heating water from the heat pump system, and was implemented as part of the domestic hot water system replacement and upgrade. The upgrades included a new high efficiency condensing water heater paired with a heating water to domestic water heat exchanger.

The pool heating system was not operational prior to the project. It was made functional and upgraded to take advantage of the low temperature heating water available from the heat pump system, by replacing the heat exchanger and adding additional controls.

Dual duct terminal boxes upgrades included replacing the terminal boxes to implement Variable Air Volume (VAV) control. In a few areas, existing single duct VAV terminal boxes were replaced with those equipped with reheat coils to facilitate occupant comfort.

The project timeline was aggressive, with engineering design starting late May 2019 and tendering in late August 2019. The project took advantage of the 2019 Christmas break to complete the majority of construction in order to minimize impacts to the occupants.

Image courtesy of Google Maps

SERVICES

Prime Consultant | Mechanical Engineering

PROJECT FEATURES

Twelve fan coil units | ~ 30 hot water cabinet unit heaters | Additional BAS integration | Dual-duct terminal boxes, upgraded from pneumatically controlled to digital control, complete with BAS integration | Domestic hot water system | Pool heating system

LOCATION

King City, Ontario

KEY SCOPE ELEMENTS

Heating plant uses ground source heat pump to deliver low temperature heating water | Compressed project schedule to meet heating season deadline | Unique dual-duct HVAC system being modernized and upgraded for re-use