CFD Analysis

Computational Fluid Dynamic (CFD) analysis uses numerical analysis and computer data structures to iteratively solve fluid dynamics problems. Practical application of this technology, while originating in highly specialized and applied fields such as aerospace, nuclear and microelectronics, has continued to evolve such that it can provide exceptional value to the design and construction of buildings.

Employing CFD analysis encourages the exchange of ideas with clients and members of the design team in order to develop a collaborative approach to problem solving. This allows for a better understanding of a problem’s driving factors from technical and business perspectives to enable smarter decisions, innovative designs and improved performance. Leveraging CFD analysis improves design efficiency and exploration, and provides a means for validating cost-effective and optimized solutions.

We have leveraged this technology to support the decision-making process during a wide range of project stages including, but not limited to, Feasibility Studies, Conceptual and Existing Design Optimization, Facility Risk Analysis, Operational and Capital Forecasting, Existing System Troubleshooting, Compliance Reviews and Value Engineering.

CFD analysis can assist with a variety of challenges related to both internal and external building systems. Typical applications include:

- Critical Cooling Equipment Capacity Studies

- IT load and Capacity Planning

- Equipment Failure and Recovery Studies

- Re-entrainment Studies

- Optimization of Acoustic Mitigation Strategies

- System Energy Performance Analysis, Energy Consumption Projection and Operational Optimization

- Air Handling Equipment, Plenum and Ductwork Design

- Outdoor Enclosure Performance including passive and forced ventilation

- Contaminant Tracing, Control, Mitigation and Purge Studies

- Pressurization Studies

- Clean Room Design Optimization

- IAQ and Thermal Comfort Analysis, including Temperature, Pressure and Humidity Control System Optimization

- Emergency Generator Performance Verifications

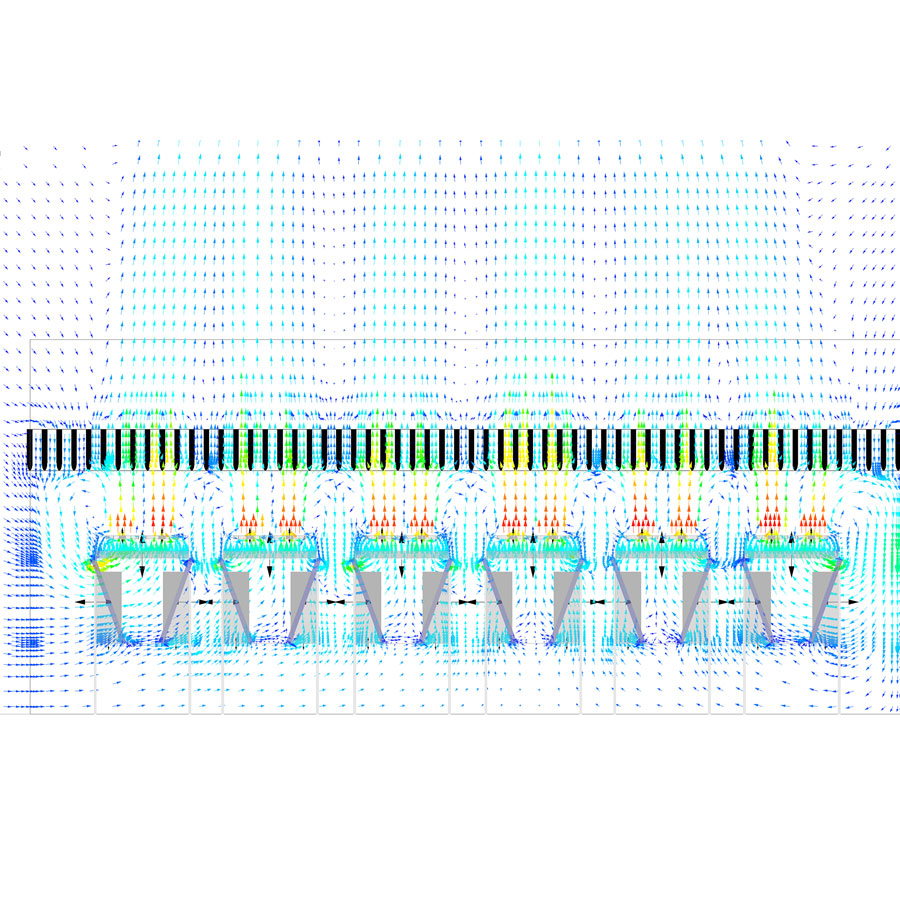

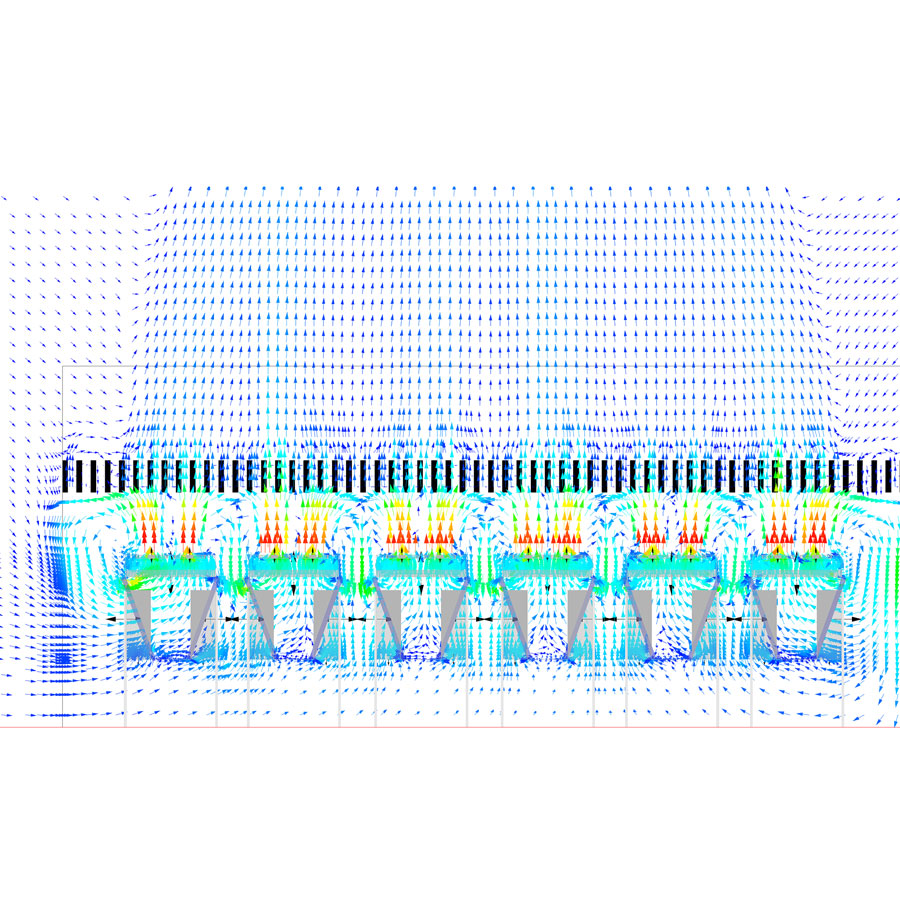

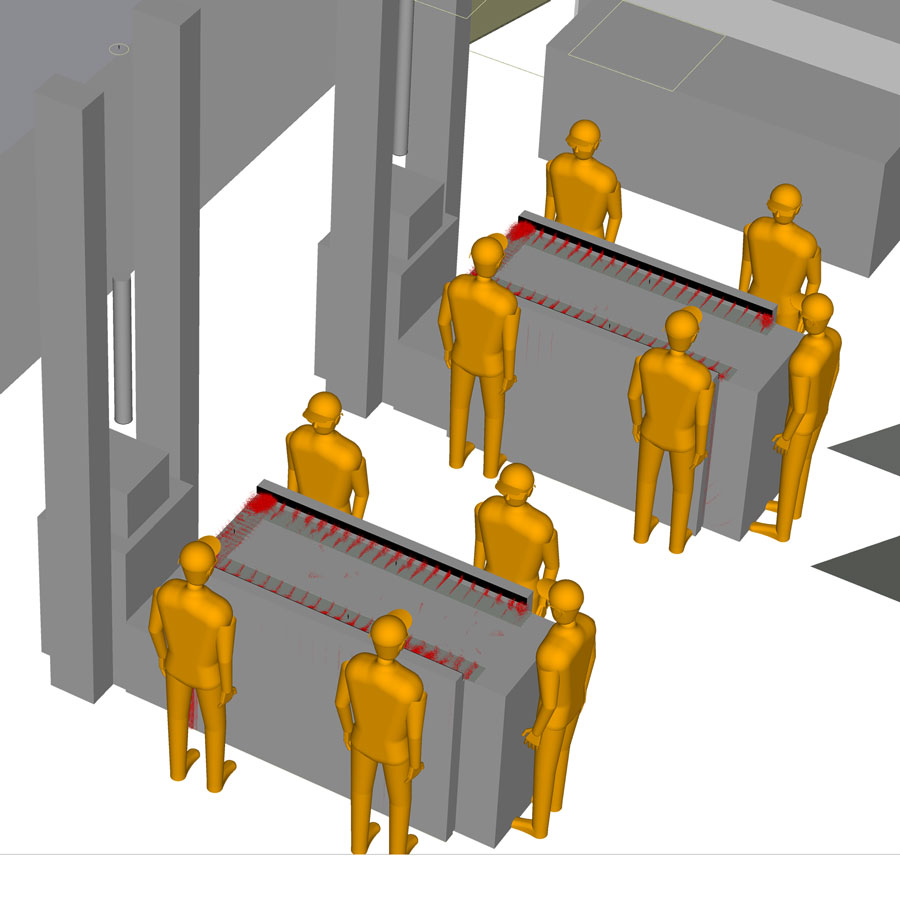

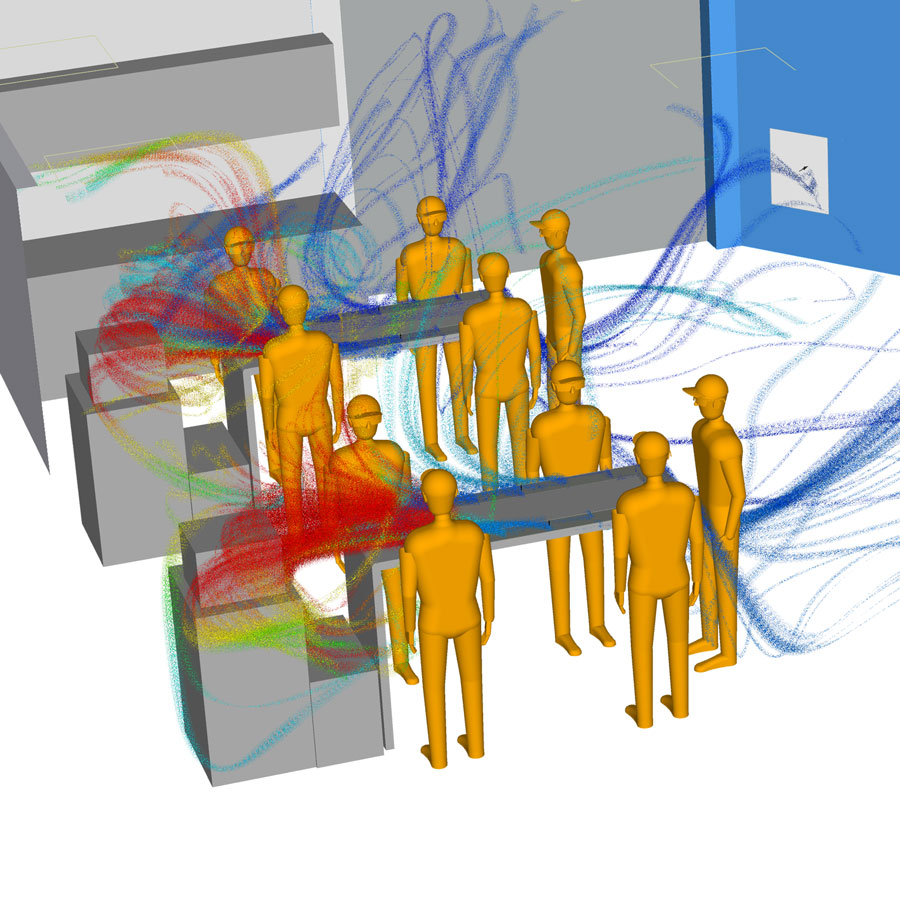

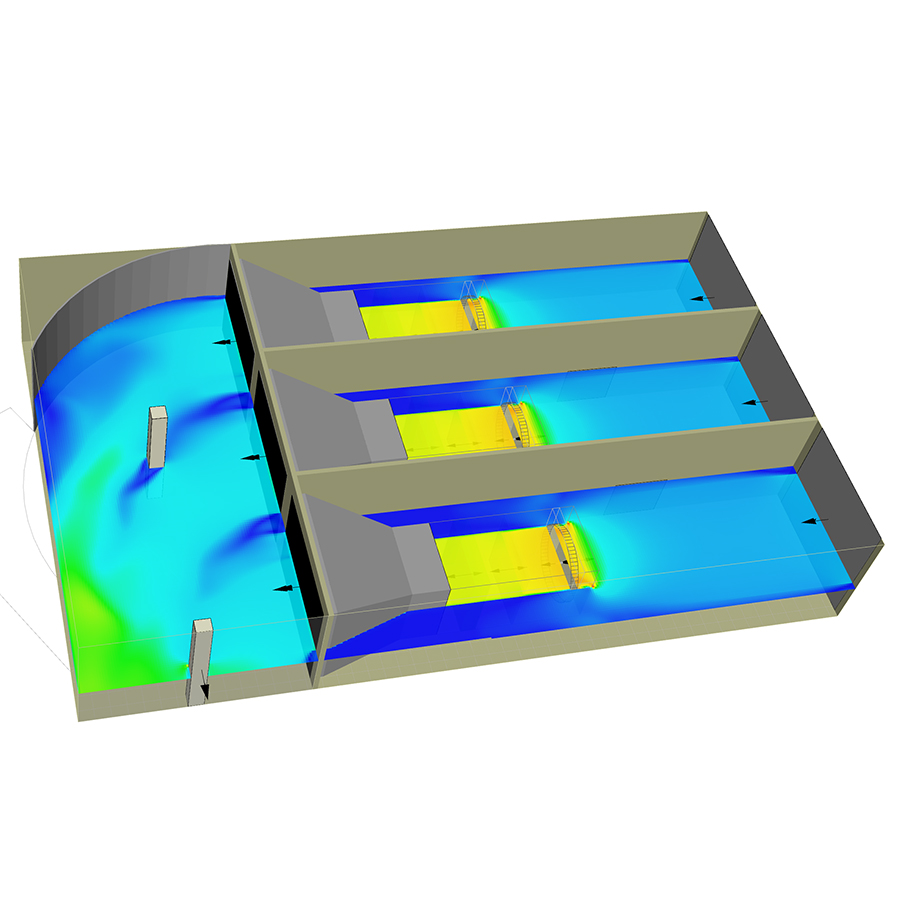

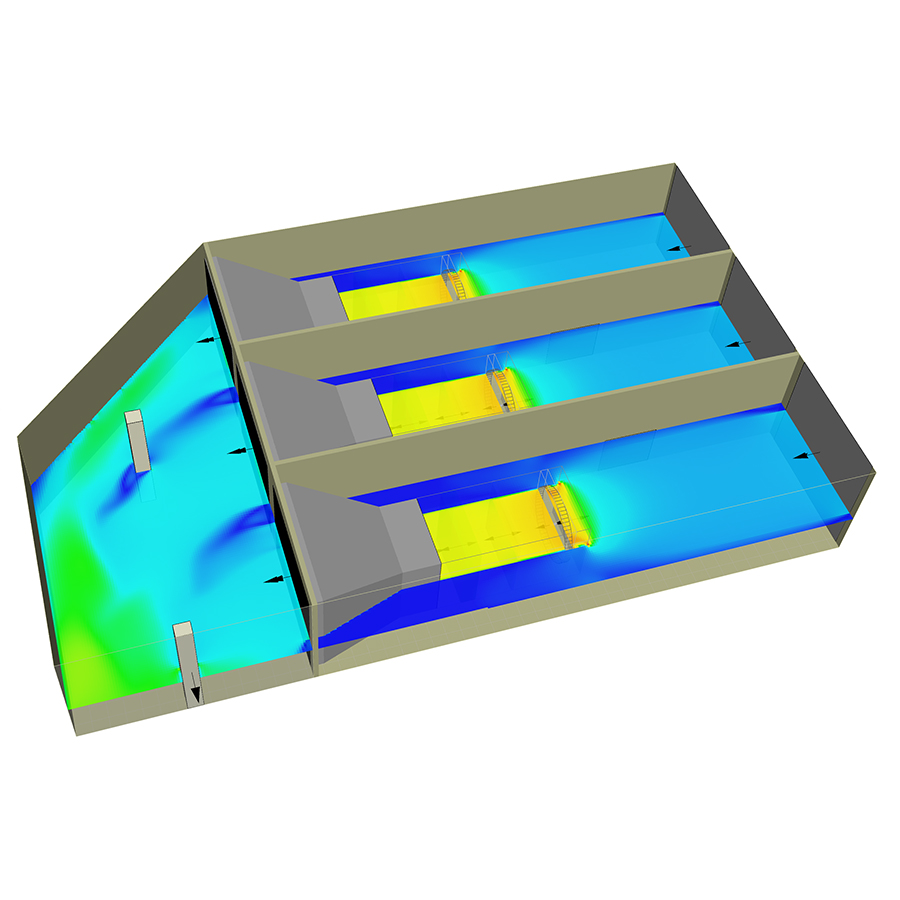

Acoustic Mitigation

Acoustic mitigation can have significant impacts on equipment performance, especially when requirements change after initial design and installation. Not only can our CFD services aid in performance validation of indoor and outdoor cooling systems, it can be used to further optimize acoustic mitigation equipment and placement for the best balance of acoustic and ventilation performance.

Examples:

- Acoustic Baffle and Louvre Analysis

- Baffle and Silencer Profile Optimization

- Acoustic Ventilation Performance

- Sound Enclosure Studies

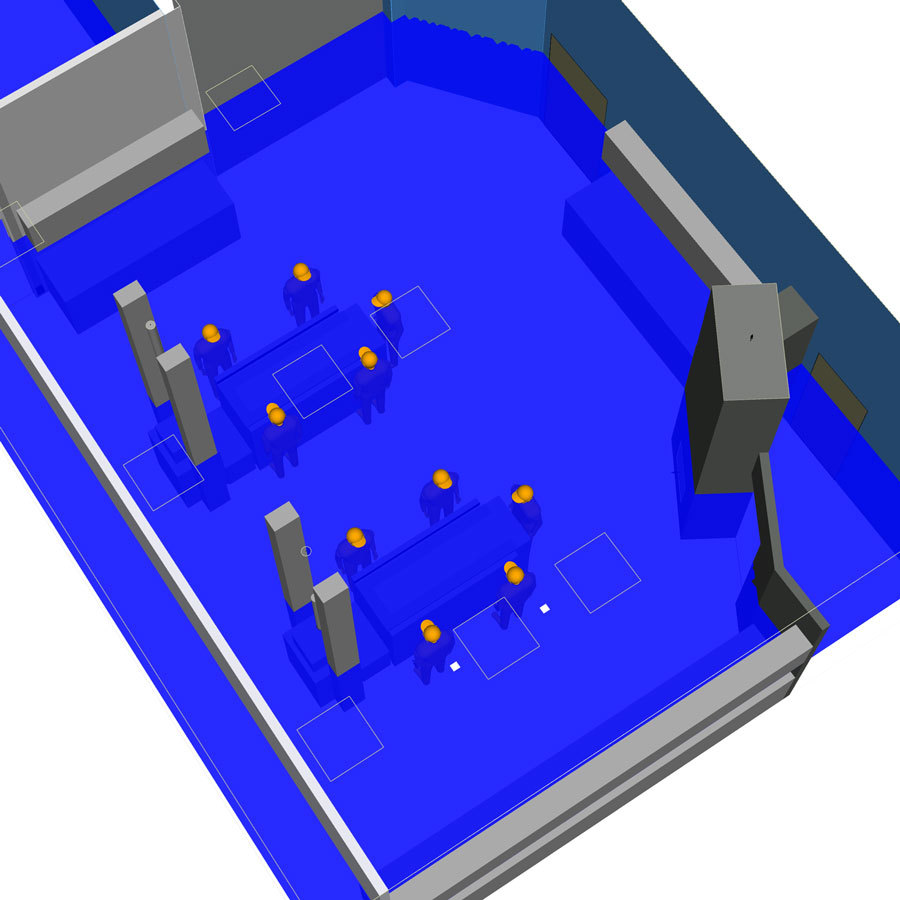

Commercial Spaces

Commercial projects often aim to balance design, sustainability and end-user suitability, both for new construction or modernization of existing facilities. CFD analysis can help align and optimize occupant comfort, energy efficiency and value. For specialty spaces, such as LAN and IT rooms, emergency generation, specialty storage and smoke extraction, upfront analysis can help validate and optimize designs for more informed decision-making that can result in capital and long-term cost savings.

Alternatively, CFD analysis can help troubleshoot operational or performance issues within existing facilities.

Examples:

- ASHRAE 55 Thermal Comfort Analysis

- Cooling Equipment Capacity and Loading Validations

- Electrical, UPS and Battery Room Optimization

- Control System Optimization (temperature, humidity, pressure)

- Setpoint, Sensor Layouts, Sequences

- Outdoor Cooling Equipment Performance

- Cooling Towers, Adiabatic Coolers, Condensers

- Equipment Retrofit, Replacement and Upgrade Feasibility

- Re-Entrainment Studies

- Generator Ventilation Systems

- Free-cooling ROI and Effectiveness

- Energy and Operating Mode Analysis

- Condensation and Pressurization Analysis

Contaminant and

Re-entrainment Analysis

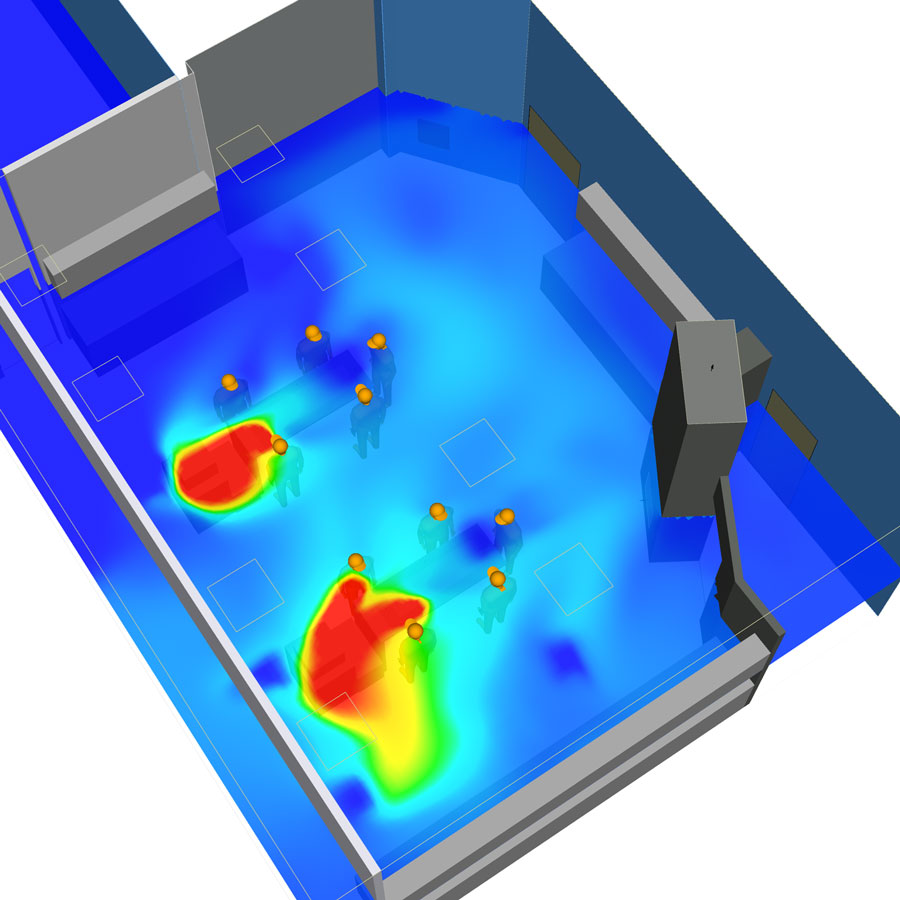

Adequate control of contaminates can be critical to the vital functions of a number of different types of facilities, especially but not limited to, laboratory, healthcare, mission critical and academic facilities.

Our CFD studies can assist clients with a number of challenges, whether for repurposing or optimization of existing spaces.

Examples:

- Contaminant and particulate tracing

- Airflow and pressurization analysis

- Wind effects on building discharges and re-entrainment studies

- Controlled, clean environments

- Lab safety and purge validation

- Ventilation air patterns

- Ventilation efficiency

- Indoor and outdoor air quality

- Temperature uniformity and comfort

Energy Analysis and Optimization

CFD analysis is a powerful tool in its own right; however, its application can be further enhanced by combining simulation output data with other key performance drivers of a facility or system, such as component energy efficiency and localized ambient environment BIN data analysis. This synergy of advanced analytic tools has allowed HH Angus to provide clients with data and insights to make informed decisions based on forecasted annualized system energy consumption for a number of operating scenarios, facility load profiles, site and environmental risk factors. Where possible, we partner with equipment suppliers to directly incorporate manufacturers' equipment performance data.

Examples:

- System energy consumption forecasting based on both internal heat loads and environmental conditions

- Control system and sequence optimization, including setpoint optimization, sensor placement sequencing to improve both total system energy efficiency, and resiliency

- Cooling system failure mode analysis including risk quantification for design day + conditions

- ROI analysis for free-cooling systems

Emergency Generator Performance Verifications

Our Design and Commissioning teams have extensive experience with generator systems due to their critical role in healthcare, mission critical, utility and industrial facilities. CFD analysis can be used to supplement our experience and services in a number of ways to achieve optimal designs and solutions.

Examples:

- Radiator fan sizing

- Silencer impact studies

- Plenum design verification

- Cooling airflow validations

- Design day and failure simulations

- Re-entrainment studies

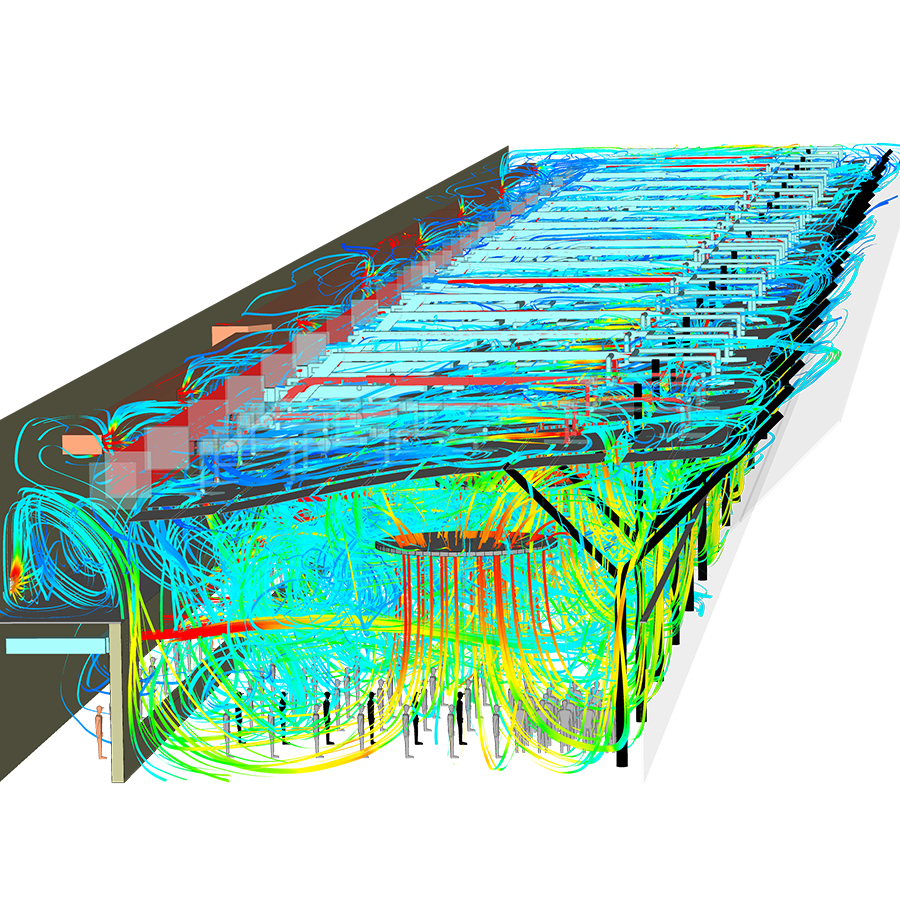

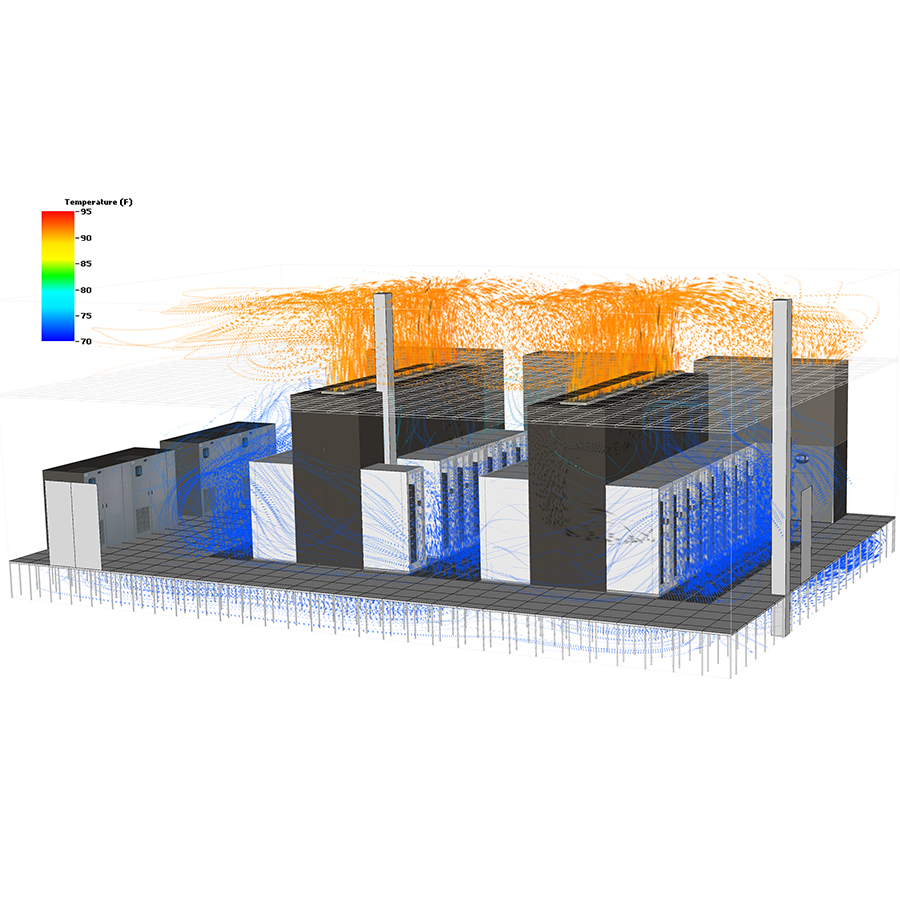

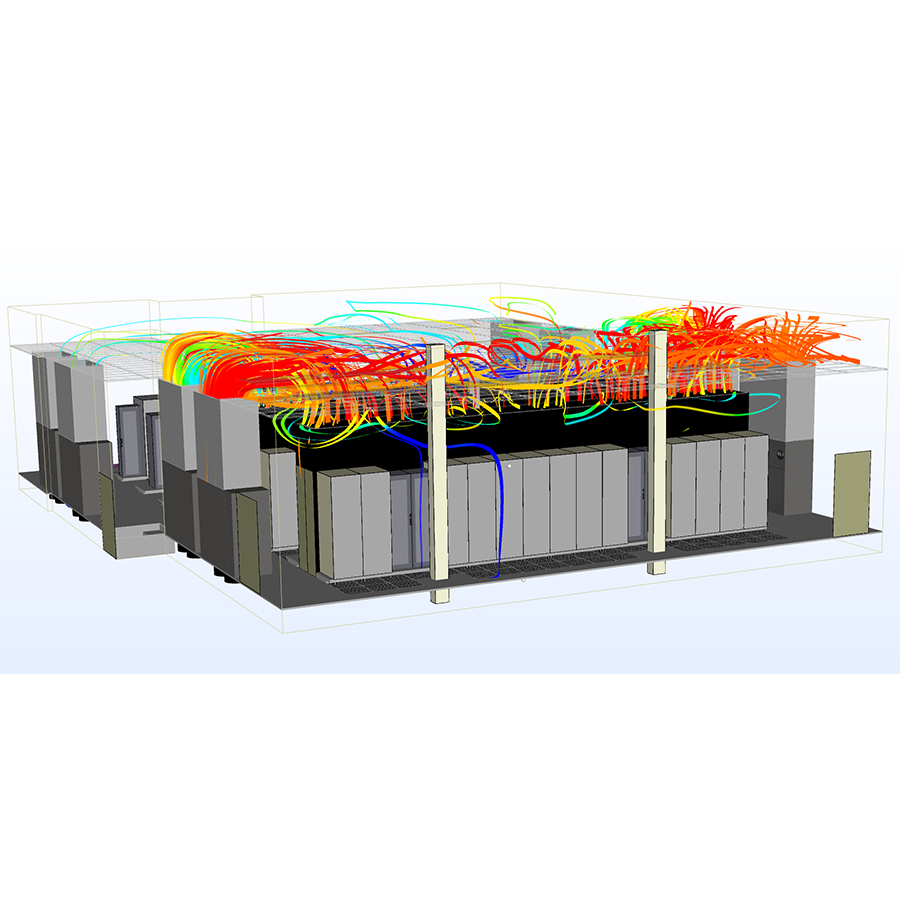

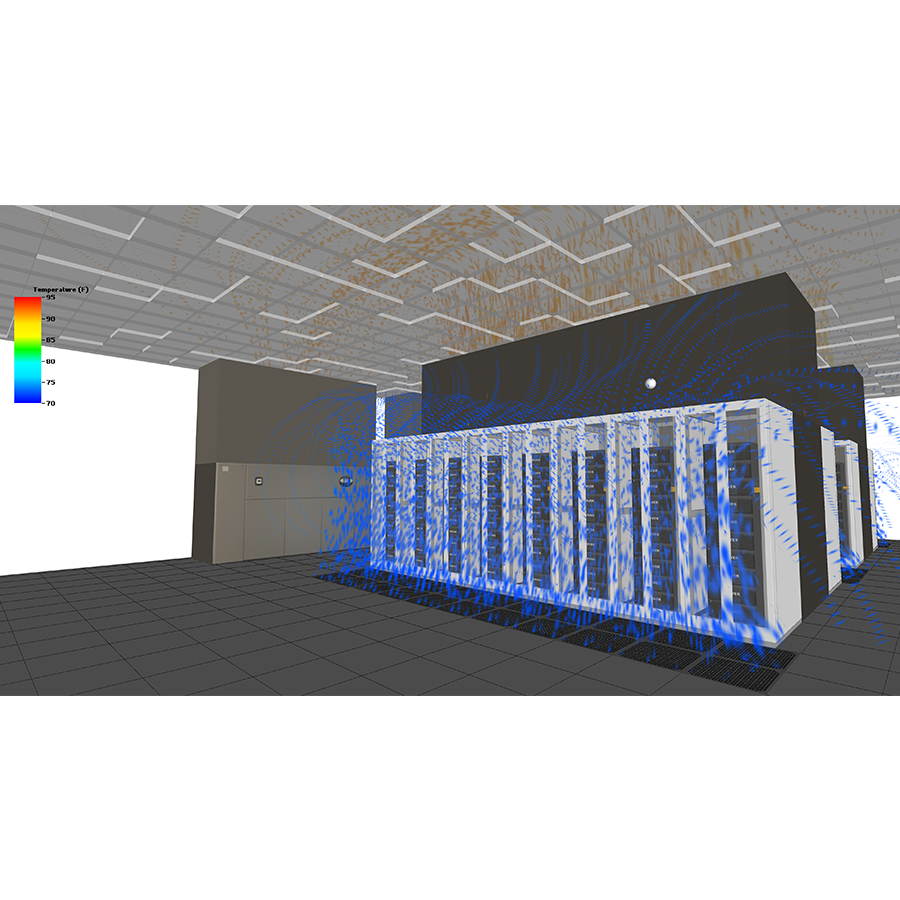

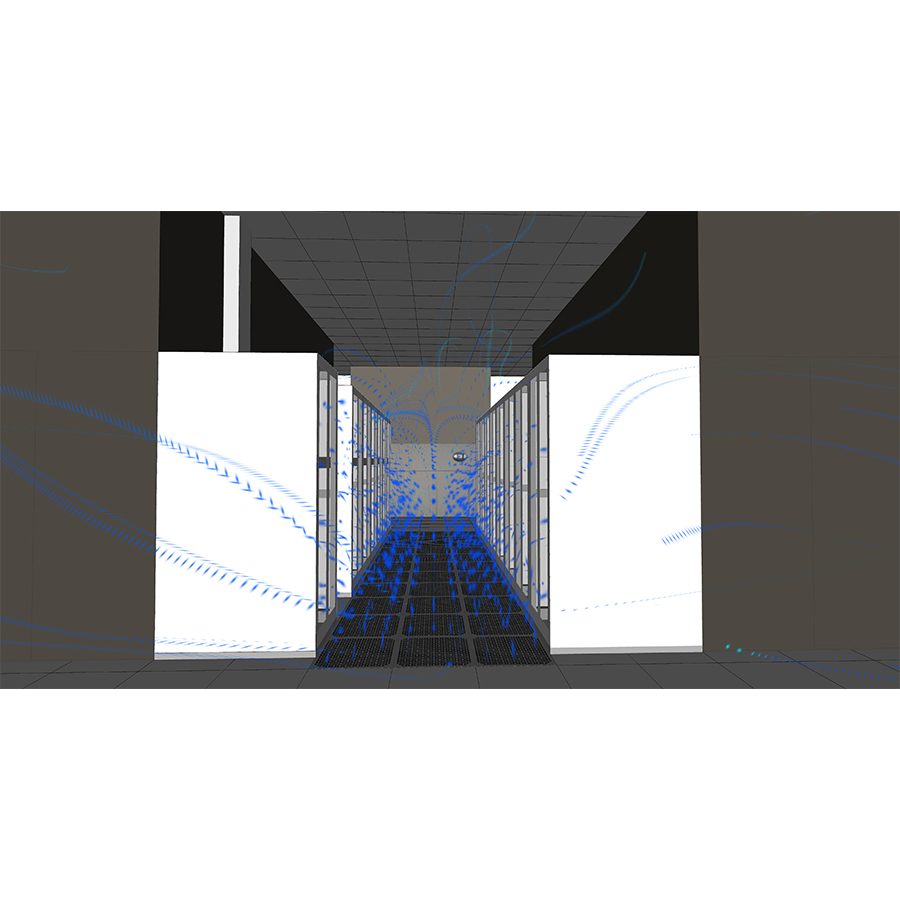

Mission Critical Facilities – Data Centre and Telecommunications

We routinely use CFD analysis where systems are engineered to provide continuous service and near-zero probability of failure, delivering innovative and dependable technology solutions wherever total system reliability is a must. Not only can key performance metrics be validated related to capacity, redundancy and reliability, but systems can be further optimized for enhanced energy efficiency. This includes highly specialized buildings such as network operation control facilities, data centres, laboratory and research buildings, telecommunications systems and transit systems.

Our CFD services can also provide insight into existing facility operational optimizations, system and performance troubleshooting, construction and maintenance phasing validations, temporary cooling simulations and more.

Examples:

- ASHRAE T.C 9.9 compliance

- IT load density optimization

- IT capacity and layout planning

- Cooling equipment capacity and loading validations

- Electrical, UPS and battery room optimization

- Control system optimizations (temperature, humidity, pressure)

- Setpoint, sensor layouts, sequences

- Failure mode analysis

- Transient overheat and cooling restart

- Battery system discharge simulations

- Outdoor cooling equipment performance

- Cooling towers, adiabatic coolers, condensers

- Retrofit, replacement and upgrade feasibility

- Re-entrainment studies

- Exhaust, purge and max cooling systems

- Generator ventilation systems

- Free-cooling ROI and effectiveness

- Containment studies

- Energy and operating mode analysis

- Energy performance vs. facility/equipment risk

- Raised floor and ductwork distribution

- Perforated tile optimization

- Layouts, damper settings, selections

- Design day and failure simulations