Hospital Substation Gas-insulated Switchgear

Located in Toronto, ON, Sunnybrook Health Sciences Centre is a full-service hospital with over 1,300 beds, making it the largest regional trauma centre in Canada. Through its partnership with Veterans Affairs Canada, it is home to more than 500 veterans. With a main campus of approximately three million square feet, Sunnybrook is redeveloping its existing main outdoor electrical substation in its entirety. The project incorporates several innovative features, including using 38 kilovolt class gas-insulated switchgear, new power transformers with increased capacity, and multiple civil upgrades. In addition to a decreased footprint and reduced maintenance requirements, the new switchgear interfaces with a networkbased monitoring and control system. In this photo, the switchgear undergoes indepth factory acceptance testing in Frankfurt, Germany.

Sunnybrook team: Michael McRitchie, Francis Jesuthasan. Prime consultant, H.H. Angus & Associates Ltd.: Philip Chow, P.Eng.

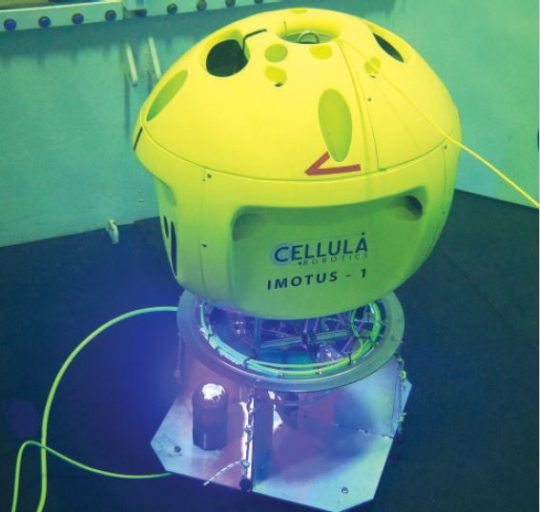

Hovering Autonomous Underwater Vehicle

In fall 2017, Cellula Robotics Ltd. successfully demonstrated its Imotus-1 Hovering Autonomous Underwater Vehicle. During a week of testing at a local pool facility, Imotus-1 navigated using proprietary Simultaneous Localization and Mapping (SLAM) algorithms and was shown to hold station, waypoint track, manoeuvre around obstacles, and dock to an underwater charging station. The docking demonstration was sponsored by Ocean Networks Canada; development of SLAM was made possible through funding from the National Research Council’s Industrial Research Assistance Program. In 2018, Imotus-1 will be used by Cellula in the North Sea for commercial survey and inspection work inside the structural legs of an offshore platform.

Eric (James) Jackson, P.Eng., Melanie Devaux, P.Eng., Paul Prunianu, P.Eng., Dr. Peter Hampton, EIT, Dana Leslie, EIT, Jacqueline Nichols, P.Eng.

Novel Polystyrene Recovery System

A.H. Lundberg Systems Limited of Vancouver designed and supplied a modular distillation system for Polystyvert for its polystyrene (Styrofoam) recycling demonstration plant in Montreal. In a novel patented process, an essential oil is used to dissolve the polystyrene at the user site, thereby drastically reducing the volume and subsequent transport costs to the recycling plant. Following recovery of the polystyrene using a liquid hydrocarbon, the distillation system separates and recovers the essential oil and hydrocarbon for reuse in the process. The module was fabricated and assembled by Acier St-Michel in Laval, QC. The plant is scheduled for commissioning in May 2018.

Allan Jensen, P.Eng., Bruce Der, P.Eng., Alex Lisnevskiy, P.Eng.

Published in Innovation Magazine

Engineers and Geoscientists British Columbia

May/June 2018