High Oxygen Demand

Due to the COVID-19 pandemic, the high oxygen demand by ventilators and related equipment can create high flow rate demands on a bulk liquid oxygen system, in excess of flow rates for which they were designed. This situation has been reported overseas where increases in flow have in cases exceeded 1000% of design capacity.

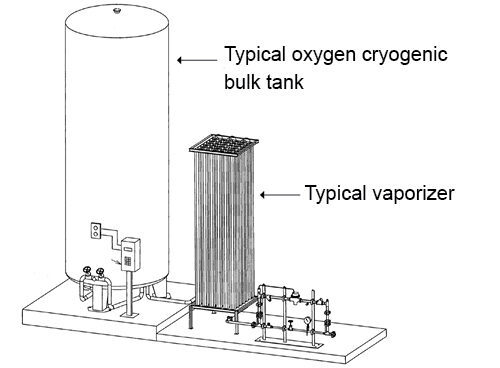

Bulk oxygen systems are owned by the medical gas supplier. They consist of a storage tank, a vaporizer, and a gas pressure regulator station as well as a reserve supply.

Bulk oxygen is stored as a cryogenic liquid at approximately -183°C, and then is vaporized to a gas by use of ambient air vaporizer(s), which uses ambient atmospheric heat. Due to the cold liquid temperature, ice does form on the vaporizer (from condensation of atmospheric humidity onto the cold vaporizer surfaces) irrespective of the outdoor conditions.

The photo on the left illustrates a partially covered surface of a vaporizer; the photo the right shows a vaporizer fully encapsulated with ice (in the middle of the photo). Both photos were taken at different hospitals in southern Ontario during the week of 30 March 2020, when outdoor temperatures were above freezing.

As ice build-up increases on the vaporizer, the ice acts as an insulator, thereby reducing the available heat transfer surface area; this reduction in surface area reduces the capacity of the system to deliver gaseous oxygen. Vaporizers are sized to allow for certain accumulation and still supply 100% design flow with some degree of safety but, past this flowrate, ice can incrementally accumulate.

During periods of unusually high oxygen demand, with reduced heat transfer capacity, this can reduce the production rate of gaseous oxygen and can also cause liquid cryogenic oxygen to be introduced into the distribution pipeline downstream of the gas pressure regulators. When this liquid evaporates in the pipeline, the very large change in volume from a liquid to a gas can create significant pressure fluctuations in the pipeline oxygen pressure.

Removal of Ice from Vaporizers

At all times, but especially at times of unusually high oxygen demand, it is important to keep vaporizers clear of ice. Contact your bulk supplier who will recommend and oversee specialist cleaning companies to perform this maintenance procedure.

Current High Oxygen Demand During COVID-19

It is recommended that a supplemental management plan during this COVID-19 event be established to monitor ice formation on the vaporizer and for ice removal, and to plan for additional high flow rate demand contingencies:

- Discuss with your medical oxygen bulk supplier if the LOX tank is being monitored daily by the supplier; if not, monitor the liquid level gauge at least two to three times a day

- Discuss with your medical oxygen bulk supplier any necessary requirements to deal with a sudden significant step change in flow demand (e.g. keep clear access to the pad for extra deliveries, be ready to support emergency technical service access, etc.)

- Discuss with your medical oxygen bulk supplier how much of the surface area can be covered with ice before the evaporator needs to be cleaned; establish response times from the supplier to have a representative on site when the vaporizer(s) need to be cleaned

- Do not attempt to remove ice. Contact your bulk supplier who will recommend and oversee specialist cleaning companies to perform this maintenance procedure

- Establish daily monitoring of ice build-up; initiate cleaning response as necessary

- Maintain the area around the evaporator clear of obstructions to airflow, for approximately 3 m if possible

- Frequently monitor the medical gas pipeline pressure for significant and unusual pressure fluctuations; this may be indicating liquid gas being injected into the pipeline, meaning inadequate vaporizer performance

- Locate (where provided) the facility emergency oxygen inlet station on the facility façade and verify the shut-off valve is operational. While the outdoor air temperature is warming, the amount of moisture in the air is also increasing, which can still pose an ice build-up problem over the next few months.

If you would like to learn more about this topic feel free to reach out to:

Ed Hood, P.Eng.,B.Eng.

Mechanical Technical Leader

edward.hood@hhangus.com

Kim Spencer, P.Eng., LEED AP

Principal | Division Director, Health

kim.spencer@hhangus.com