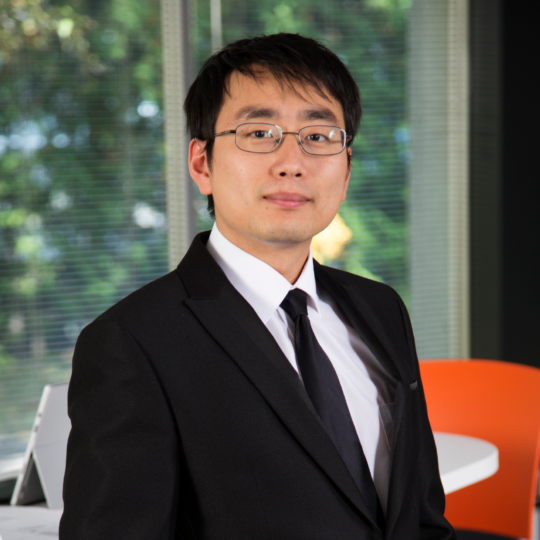

Congratulations to Tim Zhu on being chosen as one of the ‘Top 10 Under 40’ on Canadian Consulting Engineers’ annual list of outstanding young engineers.

Tim is a senior mechanical engineer and project manager in HH Angus’ fast-paced Commercial Division. Since joining the firm in 2013, he has consistently demonstrated strong technical abilities and a dedicated work ethic, often putting in extra hours to ensure clients’ work is completed with the utmost quality and care. He has also been instrumental in developing calculation tools for HH Angus, including HVAC piping and ductwork sizing tools, ASHRAE 62.1 calculation tools and more. Tim is also member of ASHRAE and enjoys the distinction of being the first HH Angus WELL APTM-accredited staff member.

Tim expresses his passion for engineering by developing standards and protocols through his work. He is a member of the HH Angus sustainability committee, the standards committee, and the calculation tools committee. Tim is currently working on overhauling HH Angus’ drafting standards to be implemented in the REVIT platform. He is also developing template control sequences and diagrams based on the ASHRAE 36 High performance Sequences of Operation for HVAC Systems. Tim regularly provides instruction and training for colleagues, including both new and experienced engineers and designers, and volunteers in University of Toronto’s Engineering & Strategies Practice course, working with students to provide real-world context to their studies.

We warmly congratulate Tim on this significant honour that publicly recognizes his outstanding efforts and qualities – well done!

To read more about this year’s Top 10 Under 40, please click here.