Welcome to HH Angus @BUILDEX

NAIT – Northern Alberta Institute of Technology

To support efficient and effective operations and prepare for strategic investments in infrastructure, NAIT engaged Angus Connect as a multi-disciplinary consulting firm to work with key stakeholders to develop plans and technical requirements for a “Smart Campus”.

-

- Smart Campus desktop study to identify best practices and lessons learned for Canadian, North American and International case studies

-

- Desktop Study, Feasibility Study, and Planning Requirements for integrated “Command Centre” to intelligently support of the smart campus operations

-

- Planning for Centralized Data and Innovation Hub to promote learning, research and industry partnerships

-

- Strategy for Information Technology Services & Integration for Smart Campus technology solutions

-

- Creation of BIM and Energy Modeling Standards, IoT Security Standard Operating Procedures

-

- Spectrum management plan for Wi-Fi and cellular with a focus on 5G-enabled devices and inbuilding augmented carrier signal

This is a greenfield community hospital which is part of a new integrated healthcare campus in Southwest Edmonton. The role of our AngusConnect team was to assist in the planning and development of project documentation for state-of-the-art, integrated Healthcare Technology Systems solutions and their application to the Project. AngusConnect was also responsible for assessing the current state of healthcare technologies, educating various stakeholder groups on emerging technologies that will impact care delivery and which are good value for inclusion in the Capital project.

AngusConnect performed jurisdictional scans and created business cases for the adoption of new technologies for the Alberta province. We are also creating the health technology specifications for a project that is to be delivered in 2030. Our advisory role is to find the balance between flexibility to allow for technology changes, firmness to prevent re-interpretation of intent, and clarity on risk transfer. The overall facility is 1,000,000 ft2.

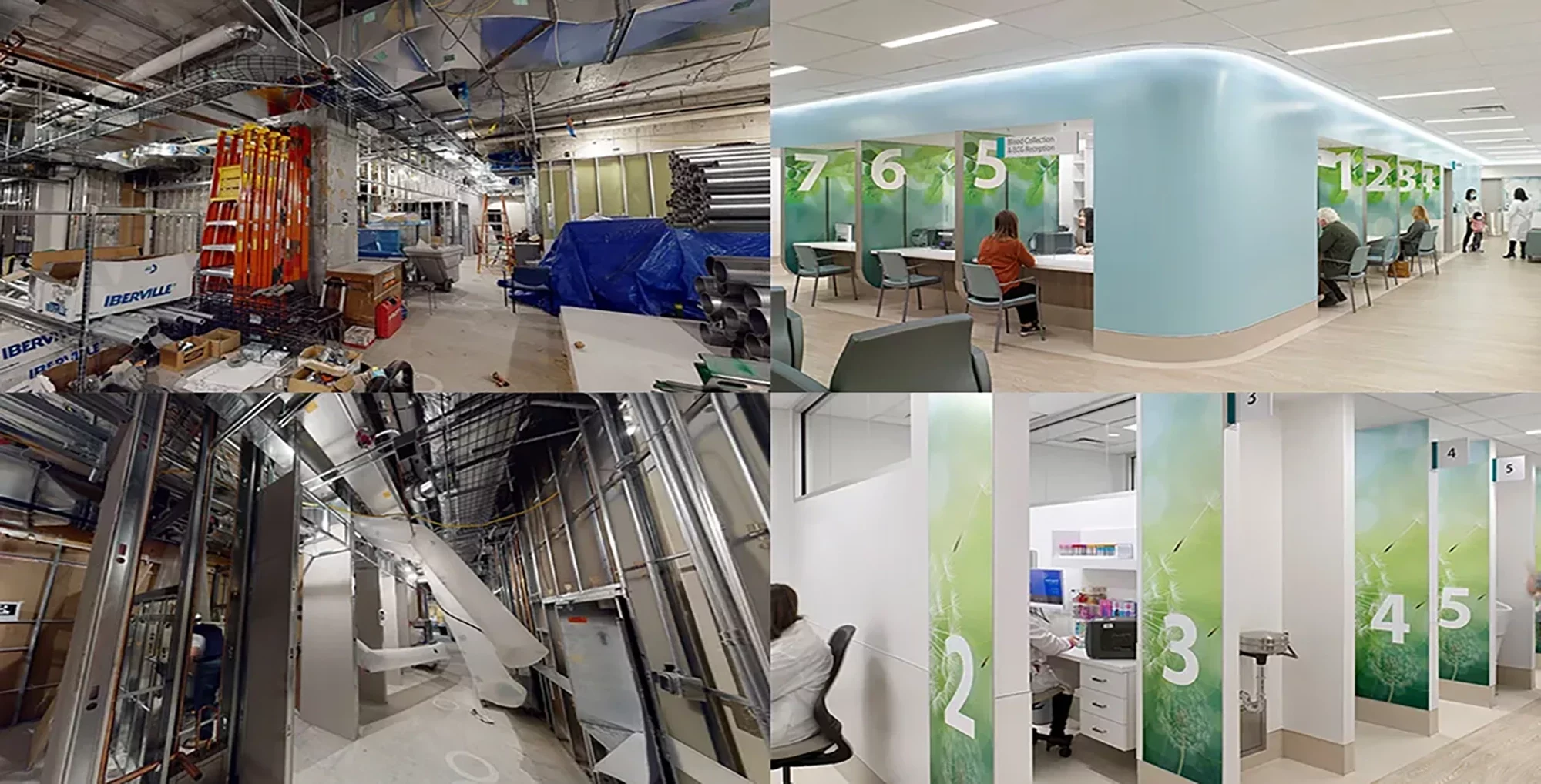

We regularly assist clients across a range of industries with virtualizing physical assets and construction summary videos. The utility of 3D scans for building owners, facility managers and consultants, both during and after construction, cannot be overstated, as it allows for highly accurate virtualization of physical spaces to improve and facilitate collaboration and problem solving. Key benefits are the ability to share construction progress with stakeholders, documentation of as-built conditions, and ease of accessibility - Matterport scans and site progress scans are all accessible with a web link and internet connection. This functionality was invaluable during the pandemic.

To see the scans in action, click on the link below. These videos were created for the University Health Network in Toronto to demonstrate to internal stakeholders the value of the Matterport platform and the capabilities of the technology - the Matterport scanner (used to document project milestones), and the Theta V 360 camera (used to capture site progress). These videos summarized site progress by collecting visual data during almost two years of construction.

HH Angus is part of the design team under the EllisDon Healthcare Infrastructure consortium, and is providing mechanical and electrical consulting engineering to the 607,000+ ft2 project. The new facility will have 204 private or semi-private beds to support best practices for infection prevention and control, with the capacity for increased beds as population growth warrants. The emergency department will be three times the size of the current ER and is expected to accommodate 42,000 visits by 2035.

-

- Prime mechanical engineering

-

- Digital consulting

-

- IoT data collection

-

- Cloud development

-

- Data analytics

-

- Engineering recommendations

- Data extraction of BAS data from the internal building network to a cloud data landing zone on AWS.

- The storage and categorization of the data in a data lake on AWS.

- Visualization of the relevant data in a dashboard and 3D model environment through Autodesk Forge.