Sector: Education

Tecnológico de Monterrey, Mexico

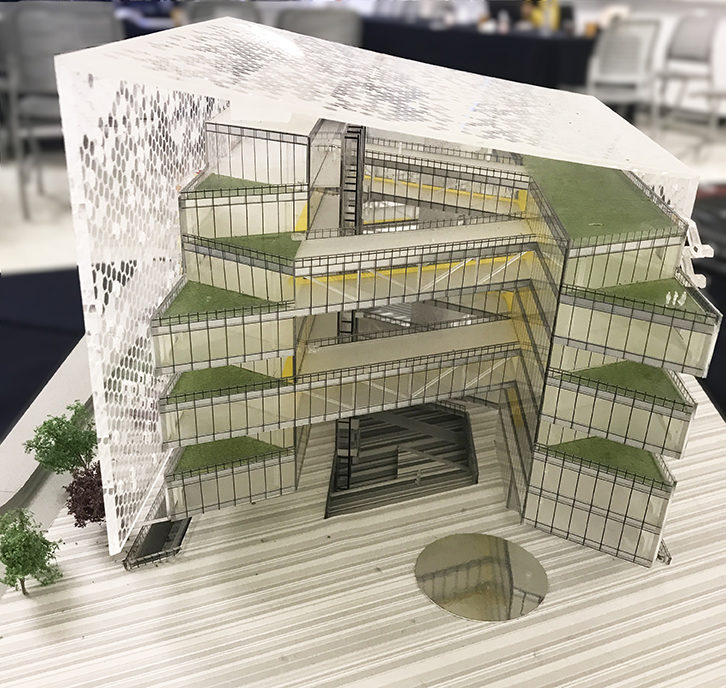

TecNano Academic BuildingTecNano is a proposed new academic building that combines a variety of lab spaces containing co-working environments. The intent is to support a highly interactive and collaborative research experience within the biotech lab building.

Tecnológico de Monterrey is a multi-campus private university in Monterrey, Mexico. The university has grown to 36 campuses throughout Mexico, with the Monterrey campus serving as its flagship institution.

HH Angus was engaged to provide ICAT (information, communications and automation technology) design services for a proposed new building, the TecNano Academic Building. The IT design scope included a main data centre with a subsidiary data centre dedicated to Multiomics. The IT design was based on a stacked central riser, with main and redundant facility entrances from the street and from the rear, connecting to the campus backbone. Wi-Fi would be available throughout the building, with lab benches and overhead carriers providing wired data connections.

The building design required an innovative solution to locating the IT backbone. We designed a riser in the exterior channel up the north side of the building to facilitate the open-air atrium as well as a stacked riser.

The security scope included access control, CCTV, duress alarms, and a central guard station with CCTV monitoring. The facility was designed with medium to high security measures, and featured dual factor credentials for specific lab entrances. There was one clean room with anteroom, and several isolation and pressurized anteroom labs, all requiring interlock and high-speed overhead doors.

Physical security also presented challenges. Intended to be welcoming, safe and secure, the facility was designed to be open to the campus on the North side and to act as a gateway to the campus from the street on the South side. We provided glass high-speed entrance portals for entrance circulation. The solution also had to function well in Monterrey’s extreme environment. Working with the architect, we provided a safe, secure, and high-speed portal that would be protected from the elements by the atrium ceiling high overhead.

The AV systems included a public auditorium with distance learning and lecture capture, video conferencing-enabled faculty boardroom, as well as AV-enabled student meeting, study, and huddle spaces. Digital signage in IP-65 enclosures provided wayfinding at the entrance for the facility and campus

The TecNano Academic Building laboratory types included:

Nanophotonics

Molecular Simulation

Metallomics

Advanced Optical Microscopy

Nanostructure Synthesis

Micro and Nanofabrication

Multiscale Manufacturing

Materials Characterization

Synthetic Biology

High Throughput Bioprocesses

Microrobotics

Tissue Engineering and Bioprinting.

SERVICES

ICAT Consultant - Security, Audiovisual and Communication Design

PROJECT FEATURES

Size: 25,500 m2 | Status: Design Completion 2018

LOCATION

Monterrey, Mexico

KEY SCOPE ELEMENTS

Biotech laboratory building, including clean room and nanotechnology labs | International collaboration – Client in Mexico, Architect in United States, ICAT and Vertical Transportation consultants in Canada

Innovative solutions

An interesting challenge affected the communications design, specifically the outside plant design. When the local municipality rejected street closures to install a communications duct bank for carrier entrance cabling, we surveyed the site, the facilities, and routing together with TecNanao IT, and designed a campus-internal route to meet the carriers’ entrance to the East. While it is a much longer route, it is also simpler to permit, as it was not located within the municipal right-of-way.

Image credits: FGP Atelier

York University

Osgoode Professional Development Centre

Osgoode Hall Law School is considered a world leader in continuing legal education. Its Professional Development Centre is located in the heart of Toronto's downtown core, at Yonge and Dundas Streets, and forms part of York University's Downtown Campus.

HH Angus provided mechanical, electrical and lighting and ICAT design for a fit-out and renovation of the 26th floor of 1 Dundas St. Spaces included the reception area, open concept workstations, meeting rooms, lounge area, kitchen, staff room, phone rooms, accessible washrooms, academic classrooms of various sizes and functions, video/audio studio, and other support spaces.

Our scope for the 17,000 ft2 space included the alteration and renovation of the base-building elevator lobby and the entire 26th floor, complete with architectural, interiors, mechanical, electrical, telecommunications, accessibility, code and life safety, space and program planning, and fully integrated Building Information Modeling. The design was based on meeting LEED CI Silver standards.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | Security Consulting

PROJECT FEATURES

Size: 17,000 ft2 renovation and fitout, meeting LEED CI Silver standards | Status: Completed 2019

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Renovations to professional development institution | Fully integrated BIM

Toronto Metropolitan University (formerly Ryerson)

Pitman Hall Food Facility

Pitman Hall, located in the heart of downtown Toronto, is Toronto Metropolitan University's second largest residence, with 14 floors and 565 rooms.

HH Angus provided electrical and mechanical consulting services for the renovation of the existing kitchen and dining facilities in Pitman Hall. The refurbishment was implemented in two phases, with the kitchen and seating area as Phase 1, and the Dining Hall expansion into Pitman Quad in Phase 2.

The objective of the renovation was to increase capacity throughout the existing facility, both in number of meals served and seating capacity.

HH Angus’ scope included review of existing building systems, preparation of mechanical and electrical designs, creation of preliminary construction and other tender documents, and identification of future mechanical and electrical space requirements.

SERVICES

Mechanical Engineering | Electrical Engineering | Security | Communications | Fire Protection | Lighting Design

PROJECT FEATURES

Status: Completed Phase 1 - 2018; Phase 2 - 2019

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Created preliminary construction and other tender documents | Identified future mechanical and electrical space requirements | Increased facility’s meal preparation capacity | Innovative ceiling lighting design

Ecological Exhaust

Increasing the meal preparation capacity of the facility presented some design challenges for the Planning, Design Consulting (PDC) team. This is usually accomplished by increasing the exhaust volume of the cooking facility; however, the location of the building was such that other nearby buildings were too close for direct exhaust. HH Angus worked closely with the kitchen consultant to design and specify a grease filtering “ecological” exhaust unit that would sit on the existing structure.

Ventilation and Lighting Design

The wave-style ceiling presented an interesting challenge to the PDC team in designing the lighting for the unique ceiling architecture. The team worked closely with the architect to create a design that would accommodate linear diffusers and lights.

University of Toronto

Leslie L. Dan Faculty of Pharmacy

Canada’s largest pharmacy school, this 167,000 ft2 teaching and research facility includes practice laboratories, research facilities, a resource centre, lecture theatres and offices for faculty, staff and graduate students. The building is 16 storeys (13 above and three below grade), and supports the academic, research and teaching needs of more than 1,300 people daily.

A ‘repeatable’ environment is fundamental in research facilities. By designing steady and stable environmental conditions, experiments can be repeated without data corruption.

Program space includes 23 labs for pharmaceutical research. Laboratory features include distribution of lab gases, on-site nitrogen generation, Type II Reverse Osmosis water, and a ganged fume hood system sized to accommodate 65 fume hoods, complete with variable volume control and glycol heat recovery systems.

Conservation measures were applied to the laboratory systems to minimize energy use while meeting stringent laboratory standards. Separate plumbing systems were designed to avoid contamination by lab waste and to collect rainwater for distribution to the Winter Garden.

Signature ‘floating’ pods anchor the lighting design for the building’s dramatic five-storey atrium. Theatre-inspired lighting is computer controlled by a dimming system that changes the evening lighting every 15 minutes. Rather than attach luminaires to the pods themselves, which would have compromised the architect’s vision, the dramatic lighting comes from 128 – 375 watt and 300 watt quartz halogen lamps attached to black theatre pipes mounted on the vertical mullions. The fixtures can be moved up or down and become part of the spatial experience.

A 12-storey central atrium brings sunlight deep into the core in other parts of the building. For the upper perimeter, a high window system enables less expensive, concealed wall-wash lighting. Echoing the geometry of the interior architecture, LEDs were fixed into the handrails of hallways and bridges for emergency lighting.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 167,000 ft2 | Status: Completed 2006

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

23 labs for pharmaceutical reserch | Practice laboratories, research facilities, resource centre, lecture theatres, and offices for faculty, staff and graduate students | Signature floating pods lighting design | Energy conservation measures implemented | 12 storey atrium

Designed for flexibility

As with all research centres, we design for future uses of the space. We plan for flexibility, to allow for future IT development, or to enable the space to be retrofitted quickly and cost-effectively.

Award-winning lighting

The Pharmacy Building has been honoured with numerous international awards and press coverage and, in 2009, the Toronto Star newspaper named the Leslie Dan lighted pods as one of “175 Reasons to Love Toronto”. At dusk, the pods mimic the setting sun, bursting with fiery reds and deep blues. Colours advance through a palette of hues, starting on one pod and flowing to the other.

Humber College

Student Welcome & Resource Centre

The Student Welcome and Resource Centre at Humber College provides a high-visibility landmark gateway to the campus, and a highly accessible focal gathering place for students and the public.

The campus gateway is a standalone facility at Colonel Samuel Smith Park, an historic agricultural parkland on the shores of Lake Ontario.

As the mechanical and electrical engineering consultant on the Planning, Design and Compliance (PDC) team, HH Angus contributed to the development of a detailed space program, room layouts and adjacencies, including space data sheets.

Our project scope included developing the design brief and schematic plans for a comprehensive PSOS (Project Specific Output Specifications). The PDC team reviewed all design submissions to ensure full compliance with the original schematic design and PSOS.

The PDC team submitted all necessary planning documents to facilitate development. This included completion of massing and setback drawings to support discussions with city planning to obtain feedback to inform the RFP. The team also attended public meetings and open houses to represent Humber’s interests and answer design-related questions.

SERVICES

Mechanical Engineering | Electrical Engineering | PDC team

PROJECT FEATURES

Size: 43,500 ft2 | Status: Completed 2017

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Detailed space program, room layouts and adjacencies, including space data sheets | Design brief and schematic plan for comprehensive PSOS | Sustainable design strategies included green roof and large areas of landscaping | Certified LEED silver

Engineering for occupant comfort

Certified LEED Silver, the four-story structure houses 43,500 ft2 of space for student services, cultural facilities, and wellness programs.

Working with nature

Sustainable design strategies included a green roof and large areas of landscaping. Full-height glazing on the east and north elevations maximize daylight harvesting while metal sunscreens and shade trees reduce solar gain in summer.