Sector: Education

Queen’s University

School of Medicine

The Queen’s University School of Medicine is a state-of-the-art multifaceted facility. This project updates, consolidates, expands and relocates the teaching, research, administrative and student facilities, which had previously been scattered across several buildings. The greenfield project was built to ensure sustained teaching and research excellence.

The building is 128,260 ft2 on five levels, plus a mechanical penthouse, and consists of a teaching facility comprising medical teaching spaces, simulation labs and surgical/technical skills labs, autopsy, microbiology and biochemistry labs and support spaces, physiology/pharmacology and support spaces, anatomy and dissection labs, two teaching theatres, medical teaching facilities and study rooms.

The design of this leading-edge facility included a fitout to enable electronic mannequins in the simulation labs, and medical gas installations to permit students to perform simulated procedures. Mechanical specifications encompassed special exhaust equipment in the autopsy rooms to evacuate chemicals used in autopsy processes and body preservation, as well as a fitout for body storage.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: 128,260 ft2 | Status: Completed 2011

LOCATION

Kingston, Ontario

KEY SCOPE ELEMENTS

Mechanical penthouse | Teaching facility comprising medical teaching spaces, distinctive labs and support spaces | Fitout to enable electronic mannequins and medical gas installations

University of Toronto

Terrence Donnelly Centre for Cellular & Biomolecular Research

University of Toronto institutions are world leaders in the quest to find the link between genes and disease. The Centre for Cellular and Biomolecular Research (CCBR) is an innovative, multidisciplinary facility and the first of its kind in Canada: an advanced research centre capable of competing with the world’s top research and development institutions.

The CCBR was designed as a highly functional, flexible and technically advanced research facility that reflects the University’s status as a world leader in the field of genome research while, at the same time, recognizing the historical importance of its neighbouring buildings.

As a sustainable and green building, the CCBR showcased the use of new and emerging materials as key elements. The double façade curtain wall was one of these unique features. It supports natural ventilation on the south side, circulating air and promoting cooling in hot weather, and acting as a thermal sink in subzero conditions. This stack effect, controlled by variable dampers, considerably reduces the heating and cooling load on the mechanical systems. The curtain wall reduces noise infiltration and decreases heat loss, with the outer leaf of the double façade functioning as a shield to buffer the interior from the urban wind tunnel of the adjacent College Street, a major city thoroughfare.

Energy conserving measures were applied to the laboratory systems to minimize energy use while meeting stringent laboratory standards. Separate plumbing systems were developed to avoid contamination of the environment by laboratory waste and to collect rainwater for distribution to the Winter Garden.

HH Angus met the challenges of this unique facility by designing and engineering systems that will allow this building to stand the test of time as an example of innovative sustainable design.

SERVICES

Mechanical Engineering | Electrical Engineering | CCTV | Security and Communications | Preliminary Vertical Transportation Review

PROJECT FEATURES

Size: 221,000 ft2 | Status: Completed 2006

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Double façade curtain wall was introduced to reduce noise infiltration & decrease heat loss | Energy conservation measures | Full Building Automation System designed

Integrating new and old

The CCBR is a 13-storey glass tower surrounded by historical buildings. With a gross floor area of 221,010 ft2, it is an outstanding example of sustainable design, comprising a range of variable space requirements: highly controlled laboratory floors are located beside naturally ventilated public spaces like the Winter Garden.

Improving efficiency with BAS

A full building automation system was designed for this building.

Siemens Canada

Algonquin College Trigeneration Plant

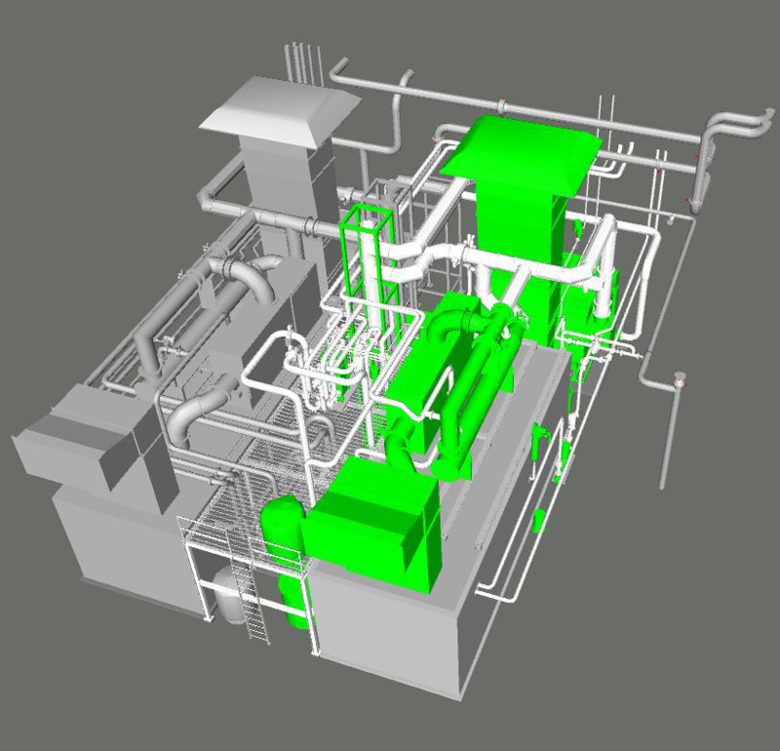

HH Angus was retained to design a trigeneration plant for Ottawa’s Algonquin College. Our scope included review of Siemens’ PSUI application to IESO, and assisting with their application. Because the existing central utility plant (CUP) was not large enough to accommodate new plant systems, our team developed a pre-engineered building to be built adjacent to the existing CUP.

As Prime Consultant, HH Angus retained Milman and Associates to undertake the required structural engineering, including a roof design to accommodate the cooling towers, rad cooler and transformer. An additional mezzanine was added to house auxiliary equipment.

In order to maximize the usable heat during summer months, a 350 ton absorption chiller, using double effect flue gas and hot water, was detailed. The 2 MW reciprocating trigeneration plant features selective catalytic reduction units and a heat recovery boiler.

Some project challenges included:

- Integrating and commissioning a trigeneration system into an operating facility

- Noise constraints due to proximity of CUP to College operations

- Space constraints due to pre-engineered building

- Footprint was maxed out based on site restrictions; HH Angus had to take into account future co-gen, chiller and ancillaries

- Ongoing upgrades in CUP heating and cooling, which HH Angus coordinated with another consultant

- Operating flexibility required for both parallel and island operation

- Solutions included: designed mezzanines in the existing CUP to house equipment and accommodate new, pre-engineered building for the second cogen and chiller; and rigorous scheduling coordination with Utility and College operations staff

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Review of PSUI application to IESO | 350-ton absorption chiller | 2 MW reciprocating trigen plant with selective catalytic reduction units & heat recovery boiler

Minimizing Disruption

All new equipment was connected to existing systems, with electrical connections restricted to well-planned shutdowns, resulting in minimal disruption to the ongoing operations of the campus.

Queen’s University

15 MW Cogeneration Facility

Acting as the Owner’s Engineer and Project Manager for Queen’s University, our involvement included: cogeneration plant design outline, equipment performance criteria, economic analysis review, the creation of project specific EPC&M contract documents, liquidated damages and insurance requirements, administration of contract documents, and life cycle analysis of tendered submissions.

The project-specific EPC&M contract included the Expression of Interest process, preparation of request for proposals (RFP) for engineering, as well as procure, construct and maintain contacts.

We also provided design review, schedule and cost management, scope control, contract administration, inspection services, commissioning assistance, and management and contract close out.

HH Angus was also retained for utility interface items, including design of the 44kV grounding transformer, transfer protection trip system and the natural gas letdown station.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2007

LOCATION

Kingston, Ontario

KEY SCOPE ELEMENTS

Plant design outline | Economic analysis review | Project specific contract documents | Contract documents administration | Life cycle analysis | Design review | Design of 44kV grounding transformer

University of Waterloo | Wilfrid Laurier University

Centre for International Governance Innovation (CIGI) Campus

“We asked for a design that sets us apart and fosters collaboration and intellectual creativity. We are very satisfied with the marvellous building that emerged.”

- Fred Kuntz, VP Public Affairs, CIGI

This new construction 100,000 ft2building is located within the CIGI campus in Waterloo, Ontario, and consists of tiered classrooms, offices and a two-storey auditorium. The Campus was honoured with the International Award for Architecture by The Royal Institution for British Architecture along with 12 other buildings globally.

HH Angus provided complete electrical, communication and vertical transportation consulting services for the new Balsillie School of International Affairs. This educational facility is in partnership with Wilfrid Laurier University, the University of Waterloo and the Centre for International Governance Innovation. It offers Masters and PhD programs.

Our Electrical scope included designing the building’s power distribution, fire alarm, emergency lighting, communications, audio visual and security systems.

A UPS system backs up the building server room to ensure critical research data was not lost during a utility power interruption. An emergency diesel generator was installed to support the essential loads throughout the building. Low voltage lighting controls and occupancy sensors were implemented as an energy savings measure.

The architect designed a large percentage of the ceiling spaces as exposed concrete. This presented an interesting challenge to our engineering design team, who delivered a solution incorporating all the electrical, audiovisual and communication services without affecting the architectural design intent.

SERVICES

Electrical Engineering | Vertical Transportation Design

PROJECT FEATURES

Size:100,000 ft2 | Status: Completed 2012

LOCATION

Waterloo, Ontario

KEY SCOPE ELEMENTS

UPS System | Emergency diesel generator | Power distribution, fire alarm, emergency lighting communications, AV and security systems | Governor General’s Medal winner for Architecture | Exceeds LEED standards, but is not LEED certified