Sector: Energy Infrastructure

CREIT

Bloor-Dundas District Energy Feasibility StudyHH Angus was engaged to conduct a feasibility study for a Low Carbon District Energy Plant serving a new, three million square foot mixed use residential and commercial development along Bloor Street in Toronto.

The full development is being implemented in several stages over ten years. HH Angus provided Prime Consultant and Mechanical and Electrical Engineering services, and developed a conceptual framework for the study.

The study considered a combination of traditional and renewable energy sources to provide heating and cooling, reviewing a range of options that included the following:

- Condensing hot water boilers, efficiency up to 90-95%

- Centrifugal water-cooled magnetic bearing chillers

- Water source heat pumps (heat recovery chillers) to provide simultaneous cooling and heating

- Air source heat pumps to provide simultaneous cooling and heating

- Ground source heat pump system

- Ambient loop system

- Sewer heat recovery system

- Combined Heat & Power (CHP) system to generate power using a gas-fired generator and to provide heat using waste engine heat, with overall generator efficiency up to 80%. CHP can be used as backup power source and to reduce energy cost during periods of peak cooling and electrical demand.

HH Angus conducted calculations of estimated heating, cooling and electrical loads, plus energy consumption for future development, establishing options for the arrangement of the District Energy plant, including provision for expansion to provide heating and cooling to future developments in the neighbourhood.

Our study scope also included tentative District Energy plant layout and area requirements, capital budget, operating costs and NPV estimates for each option, as well as analysis of results and corresponding recommendations.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: Low carbon district energy study | Due diligence engineering report | Status: Completed 2018

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Assessment of district energy plant designs to serve 3 million ft2 of mixed use development | Calculation of estimated heating, cooling and electrical loads and energy consumption for future development | Analysis of results and corresponding recommendations for optimal design | Consideration of traditional and renewable energy sources

Mirvish Village

Central Utility Plant

Mirvish Village is reimagining a 4.5 acre section of Toronto's Bloor/Bathurst neighbourhood, including the former site of the the iconic Honest Ed's store, a beloved Toronto landmark. Featuring four high-rise, one low-rise and twelve heritage buildings*, the mixed-use site will be home to more than 2000 residents.

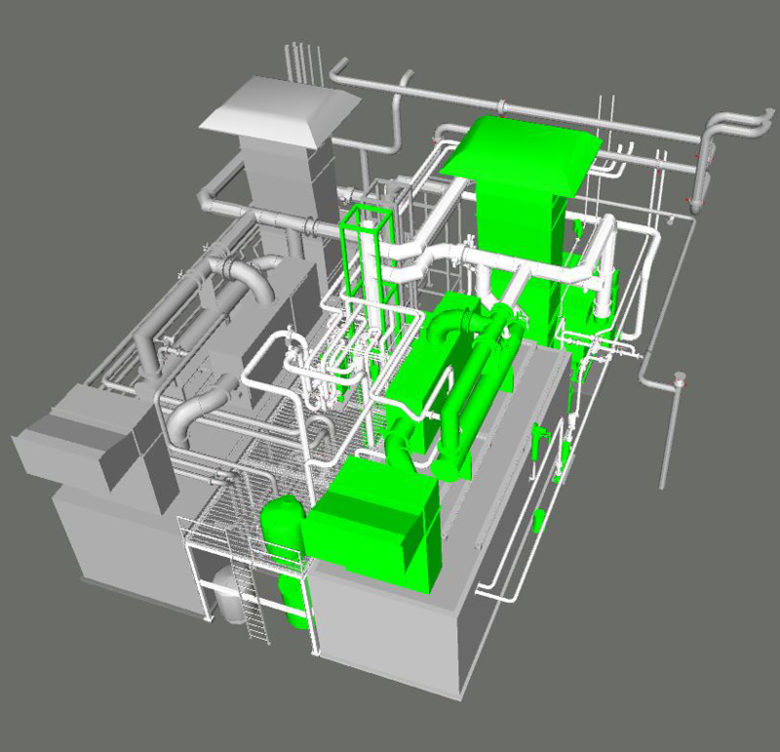

HH Angus is working with Creative Energy Developments to provide mechanical and electrical engineering services for the Mirvish Village central utility plant, which includes a combined heat and power plant (CHP), a boiler plant, and a cooling plant. The CHP plant will include an 800 KW generator set with auxiliaries and heat recovery system. The generator is expected to run continuously to provide power to the complex.

Heat recovery consists of two systems: High Temperature to provide heat to buildings, and Low Temperature to provide additional heating for a winter snow melting system and swimming pool heating. The boiler plant will include installation of four condensing hot water boilers, with the option for two additional boilers in future. All boilers will have an output of 3.1 MW.

The cooling plant will include installation of two water-cooled chillers, operating at 1200 tons each. One chiller is a magnetic bearing chiller with variable frequency drive (VFD), and the other is a centrifugal chiller with VFD. As well, two cooling towers at 1200 tons each will be installed on the roof.

Central distribution piping from the plant will provide hot water and chilled water to multiple energy transfer stations, with heating, cooling, and domestic hot water heat exchanges for each building within the complex.

The photo-voltaic solar system will have a capacity of 103KW, 480V. HH Angus is providing direction for locating the installation, coordinating with the PV supplier for modeling the panel direction and angle for optimal PV output, developing technical connection requirements with Toronto Hydro, and identifying requirements for parallel generation with the central utility plant.

We also assisted the client with a successful incentive funding application. Ultimately, the incentive was not applicable due to schedule changes, which meant the project could not meet the incentive deadline.

* The World Architecture News Awards

This international organization recognized Mirvish Village with a Bronze Award in their 2023 world-wide competition. The project won in the category of 'Future Projects'. According to the judges, "Integrating old and new, small-scale buildings and towers, it proposes a dynamic, dense and diverse micro-city with the perfect scale to enjoy as a pedestrian."

Renderings courtesy of Westbank Corp.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completion 2022

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Combined Heat and Power Plant | Boiler Plant | Cooling Plant | High Temperature and Low Temperature Heat Recovery Systems | Photo Voltaic System

Metering Strategies

Our scope also included developing thermal and electrical metering strategies within a microgrid system, design of operation for gas-fired emergency generators in electrical peak shaving mode, and the design of a roof mounted PV solar system.

Sustainable design

Mirvish Village is being designed to meet LEED® Platinum ND standards, and will feature sustainable transportation options.

Siemens Canada

Algonquin College Trigeneration Plant

HH Angus was retained to design a trigeneration plant for Ottawa’s Algonquin College. Our scope included review of Siemens’ PSUI application to IESO, and assisting with their application. Because the existing central utility plant (CUP) was not large enough to accommodate new plant systems, our team developed a pre-engineered building to be built adjacent to the existing CUP.

As Prime Consultant, HH Angus retained Milman and Associates to undertake the required structural engineering, including a roof design to accommodate the cooling towers, rad cooler and transformer. An additional mezzanine was added to house auxiliary equipment.

In order to maximize the usable heat during summer months, a 350 ton absorption chiller, using double effect flue gas and hot water, was detailed. The 2 MW reciprocating trigeneration plant features selective catalytic reduction units and a heat recovery boiler.

Some project challenges included:

- Integrating and commissioning a trigeneration system into an operating facility

- Noise constraints due to proximity of CUP to College operations

- Space constraints due to pre-engineered building

- Footprint was maxed out based on site restrictions; HH Angus had to take into account future co-gen, chiller and ancillaries

- Ongoing upgrades in CUP heating and cooling, which HH Angus coordinated with another consultant

- Operating flexibility required for both parallel and island operation

- Solutions included: designed mezzanines in the existing CUP to house equipment and accommodate new, pre-engineered building for the second cogen and chiller; and rigorous scheduling coordination with Utility and College operations staff

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Review of PSUI application to IESO | 350-ton absorption chiller | 2 MW reciprocating trigen plant with selective catalytic reduction units & heat recovery boiler

Minimizing Disruption

All new equipment was connected to existing systems, with electrical connections restricted to well-planned shutdowns, resulting in minimal disruption to the ongoing operations of the campus.

Queen’s University

15 MW Cogeneration Facility

Acting as the Owner’s Engineer and Project Manager for Queen’s University, our involvement included: cogeneration plant design outline, equipment performance criteria, economic analysis review, the creation of project specific EPC&M contract documents, liquidated damages and insurance requirements, administration of contract documents, and life cycle analysis of tendered submissions.

The project-specific EPC&M contract included the Expression of Interest process, preparation of request for proposals (RFP) for engineering, as well as procure, construct and maintain contacts.

We also provided design review, schedule and cost management, scope control, contract administration, inspection services, commissioning assistance, and management and contract close out.

HH Angus was also retained for utility interface items, including design of the 44kV grounding transformer, transfer protection trip system and the natural gas letdown station.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2007

LOCATION

Kingston, Ontario

KEY SCOPE ELEMENTS

Plant design outline | Economic analysis review | Project specific contract documents | Contract documents administration | Life cycle analysis | Design review | Design of 44kV grounding transformer

Enwave Energy Corporation

District Energy System Cogeneration Plant

District energy is a key component of Toronto’s climate action plan, to reduce emissions from buildings and help the City reach its greenhouse gas (GHG) reduction target of 80% by 2050. Buildings currently generate about half of the GHG emissions in Toronto.

Enwave is the largest District Energy Systems in North America. The system has enough power to supply over 180 office buildings.

This project started in 1962 with an original feasibility study and culminated in the design and construction of a central plant and distribution system with an installed capacity of 800,000 lbs. of steam per hour.

The deep lake cooling system was added later, and makes use of the 40°F/4°C water in Lake Ontario. It has a total capacity of 75,000 tons of refrigeration, which is sufficient to air condition 3.2 million m2 / ~34 million ft2 offices.

Clients with whom we have worked on the Enwave District Energy System include:

- Hudson Bay Company

- Bank of Nova Scotia

- Cadillac Fairview Toronto Dominion Tower Plaza

- Royal Bank Plaza

- Mt. Sinai Hospital

- Toronto General Hospital

- Women’s College Hospital

- The Hospital for Sick Children

- Li Ka Shing Knowledge Institute

- St. Michael’s Hospital

SERVICES

Prime Consultans | Project Mangeres | Electrical Engineers | Mechanical Engineers

PROJECT FEATURES

Status: Complete 2019

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Provided technical advisory for heating and colling systems | Introduced over 5 miles of piping for high-pressure steam district heating | The deep lake cooling system makes use of 40°F/4°C water in Lake Ontario

Supplying miles of steam

The system supplies high-pressure steam for district heating via an underground distribution system of over five miles of piping in downtown Toronto.

Trusted advisor

HH Angus has served as a technical advisor to Enwave over many years, consulting on various engineering aspects of the heating and cooling systems.