Sector: Hospitality/Entertainment

The Town of Jasper

Jasper Activity & Aquatic Centre

A key part of the heart of the community, the Jasper Activity and Aquatic Centre is used extensively year round. Originally just an outdoor pool with a small stone change room built in the 1920s, it has been transformed into a major facility with ice rinks, curling rinks, meeting rooms, daycare and a senior centre.

HH Angus was responsible for the engineering and design for approximately 25,000 ft2 of renovations to the main entrance lobby, daycare, administration offices, as well as a new 5,000 ft2 open concept space for the fitness centre relocation.

Sustainability, health, wellness and community were key goals, supported by use of natural materials, daylighting and special features such as a green roof, photovoltaic cells and storm water collection and reuse.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 25,000 ft2 | Status: Completed 2011

LOCATION

Jasper, Alberta

KEY SCOPE ELEMENTS

Mechanical and electrical engineering & design for ~25,000 ft2 of renovations | New 5,000 ft2 open concept space for fitness centre | LEED Silver Certified

The Granite Club

Aquatics Complex

The fourth Granite Club opened in 1972 on a beautiful twenty-two acre site on Bayview Avenue, bordering Toronto’s Don Valley. HH Angus was an integral part of the design and construction team for this premier facility, which provides members with one of the most complete and well-equipped athletic facilities in Canada.

HH Angus is privileged to enjoy a 40-plus-year relationship with the Granite Club and has been involved with many upgrades to the 80,000 ft2 structure since it opened.

The mechanical, electrical and lighting design for the Aquatic Complex renovation included features such as a competition-scale swimming pool, training pool, whirlpool, and children’s pool with water features. Design of the addition also addressed the retractable roof and retractable perimeter walls.

The retractable roof posed a challenge for our lighting design team, who had to identify the location of the fixed structural members and incorporate the appropriate lighting design to address the sloped roof. The solution was the selection of luminaires and supporting details on the fixed structural members of the roof construction, accommodating the retractable roof elements.

HH Angus has also designed upgrades to seven squash courts, four badminton courts, eight curling rinks and separate skating rink, bowling alley, outdoor lawn bowling area, six tennis courts, and a fitness centre.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 80,000 ft2 | Status: Completed 2008

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Electrical, mechanical, & lighting design for expansion including competition-scale swimming pool, training pool, whirlpool, and children's pool | Retractable roof and retractable perimeter walls

Upgrading sports and fitness facilities

HH Angus has also designed upgrades to seven squash courts, four badminton courts, eight curling rinks and separate skating rink, bowling alley, outdoor lawn bowling area, six tennis courts, and a fitness centre.

— Photos Courtesy Granite Club

Woodbine Entertainment Group

Mohawk Racetrack

Woodbine Entertainment Group (WEG) is a longstanding and valued client, dating back to the late 1980s. Through our successes at Woodbine over the years, and the development of a strong relationship, we are privileged to fulfill the role of trusted advisor.

Mohawk Racetrack is a Canadian racetrack for Standardbred horse racing programs, owned by WEG, (formerly the Ontario Jockey Club).

At the Mohawk site, we engineered the addition of a 1250kW diesel generator and associated distribution equipment, which provides complete backup emergency power, plus redundant back up emergency power to the Slots floor.

HH Angus was also responsible for providing upgrades and new construction for the grandstand, including a new grandstand enclosure, M&E upgrades to the kitchens, and mechanical infrastructure upgrades to the chiller and boiler systems.

Additional work included:

- Racing improvements

- Slots/Gaming Floor renovation and expansion

- New administration area

- Site lighting

- Site electrical distribution upgrades

- Mechanical upgrades to chiller/boiler systems

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 1999

LOCATION

Milton, Ontario

KEY SCOPE ELEMENTS

Addition of 1250kW diesel generator and relevant distribution equipment | Upgrades and new construction for grandstand enclosure | M&E upgrades to chiller and boiler systems

City of Waterloo

Waterloo Recreational Complex

The Waterloo Recreation Complex consists of a 3,500 seat multipurpose arena, an eight lane, 35 metre swimming pool with a 400 seat gallery, a rolling bulkhead, a moveable floor, a leisure pool with slide, a whirlpool, tots pool, meeting and fitness facilities and a banquet bar area with a view of both the pool and the arena. Extra seating for an additional 2,000 people can be accommodated by temporary bleachers surrounding the rubberized running track which encircles the arena.

HH Angus provided design services for mechanical, electrical, and lighting, as well as contract administration for the construction of the sports complex.

A fully integrated ammonia/brine refrigeration system was installed for ice making and air conditioning, utilizing ice storage. Ice rink compressors were used to charge ice storage tanks for air conditioning, compressor heat recovery for building and pool heating, and airside heat recovery.

The ice making plant is comprised of four 50hp ammonia compressors and a single chiller. Ethylene glycol is distributed to make the ice surface, and the temperature of the ice can be customized to suit ice hockey, figure skating or curling. The ice rink is used 18 hours per day, seven days week, for 46 weeks of the year, and the facility is fully air conditioned.

In addition to maintaining the ice surface, any excess cooling capacity in the ice making plant is used to make ice, which is stored for reducing peak consumption of electricity of the air conditioning cooling plant. The rink also features a vacuum sand filter system,

The Complex was among only ten such facilities in Canada, the United States, Europe, and Australia to be honoured with the 1995 Award of Merit from Athletic Business Magazine.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 1993

LOCATION

Waterloo, Ontario

KEY SCOPE ELEMENTS

Installation of fully integrated Ammonia/Brine refrigeration system | Ice rink compressors used to charge ice storage tanks for air conditioning | Compressor added for heat recovery for building and pool heating

Stadium Corporation

Rogers Centre

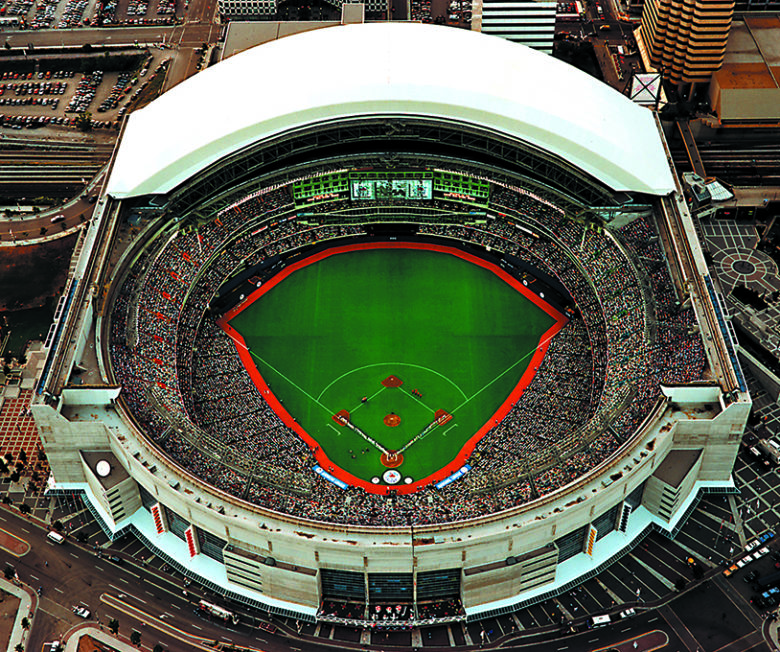

Rogers Centre (formerly ‘SkyDome’) is a versatile entertainment centre accommodating a variety of events. HH Angus provided mechanical and electrical engineering for the SkyDome, as well as vertical transportation design, lighting design and inspection. The ‘Dome’ was a milestone project for HH Angus and Toronto – the world’s first domed stadium with a fully retractable motorized roof.

In 1989, the innovative facility made Toronto the envy of cities around the world. Harry Angus, now CEO and Board Chair, recalls the intense pressure on HH Angus’ team leading up to the opening. Walking the entire venue prior to opening, he was the engineer who signed off on the building’s fitness for occupancy; it was a heavy responsibility as he detailed the final work requirements that would ensure the safety and comfort of more than 50,000 people beginning with the opening night gala.

The late Peter Willings was HH Angus’ Principal in Charge. His initial involvement was on the feasibility study team, whose task was to determine if a stadium with a retractable roof was even possible. The team's report concluded that it was. The study team then had to frame the design competition rules. It was at that point that we had to make a choice whether to stay on in our existing role, or to join a bid team. HH Angus was invited to join Rod Robbie’s bid team, and Willings cited Robbie’s ‘well-thought-out plan’ as a key to winning the project.

Tom Halpenny, now HH Angus’ Vice President and General Manager, was the Lead Mechanical Engineer and Project Manager: “It was a very challenging project. The design kept changing as we went along but Opening Day didn’t move; for example, the entire SkyDome hotel, a 350-bed building, was an afterthought; it was added when design was 75% complete. The Sky Boxes were also added late in the design phase, as was the decision that the field should double as tradeshow space, so we had to quickly design systems to support that use. Football was added to the event schedule, and that meant seats suddenly had to be movable. Many other design ideas came and went, including a cable car inside the Dome. But, through it all, we had a really good team – the architect, Rod Robbie, was a tremendous person to work with, as was his team; also EllisDon as the contractor, and our entire HH Angus team. We communicated well and regularly, and everyone respected the expertise of the other team members.”

One of the biggest design challenges our team faced was how to design a mechanical system that had all the usual system elements but no roof to go through. As Tom points out, “this had never been done before. As the ‘bents’ (vertical cement trusses) were poured, we would design for the resulting space. But it was interesting - the Design Build became more of a Build Design!” For several years afterward, Tom led tours of the mechanical and electrical spaces at the SkyDome for ASHRAE groups, students and various service clubs.

For Lead Electrical Engineer Fred Hucaluk (Ret.), a particular feature of the building stands out - the lighting control system for the 800 - 2000 watt metal halide floodlights mounted in six steel framed banks under the roof sections. “After reviewing the problems of Montreal’s ‘Big O’ stadium, where the lighting control system was a basic system similar to an office building, and required an operator at each lighting bank with a walkie-talkie on opening day, we opted for a remote control system with a hard-wired back-up, as well as the basic digital control. The remote control relays at the lighting banks, controlling only two 2 kW fixtures, had a local tog control at the lighting panels. This allowed for lighting for all the major sporting events, as well as concerts and theatrical productions.”

SERVICES

Mechanical Engineering | Electrical Engineering | Vertical Transportation Consulting | Communications Design

PROJECT FEATURES

Status: Completed 1989

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

World’s first stadium with a fully retractable motorized roof | 350-bed hotel | Moveable seating to accommodate other events | Remote controlled lighting system

Award-winning lighting

The complex’s award-winning lighting was designed by HH Angus. The lighting design for the playing surface, with over seven hundred and seventy 2000 watt floodlights, won the IES Paul Waterbury Award of Excellence in 1990. HH Angus was also awarded the Edwin F. Guth Memorial Lighting Design Award of Merit for the lighting in the SkyDome Hotel.