Service: Electrical Engineering

The Co-operators Calgary

Tenant Fitout

This project focused on a tenant renovation of two floors in The Co-operators' newly-acquired downtown Calgary office space, and comprised 40,000 square feet. The project has been certified WELL Gold.

Our approach included early coordination with the landlord to ensure handover conditions suited the client’s requirements, as well as close coordination with the construction manager in creating a pre-order due to a condensed construction schedule.

The construction schedule was a key challenge of the project along with the timing of tender. The completion date was an unmovable milestone as the client’s lease was expiring at their other location. At time of tender, product and material availability were fluctuating, which created uncertainty around delivery. To meet the deadline, our team was tasked to do everything possible to ensure the success of the project and keep the schedule on track.

To help ensure timely delivery, our team incorporated a pre-order package for the construction manager to tender, which allowed products to be reviewed and released ahead of the official tender. This effort was successful and was completed according to plan; however, some delivery delays were unavoidable, due to market conditions. To mitigate the impact, we were then tasked with contacting industry partners to help expedite deliveries. In addition, alternative temporary designs were implemented to ensure the move-in date could be met by planning the switchover date once the outstanding equipment arrived.

The Calgary office marks our fifth tenant improvement project for The Co-operators, following similar fitouts for their locations in Guelph ON and Regina SK, as well as pilot projects in Montreal QC and Burlington ON.

New Lutron lighting control design

New UPS N+1 Design and new LED Lighting Design

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | Communications & Security Design

PROJECT FEATURES

Size: 40,000 ft2 over two floors | Status: Completed 2023

LOCATION

Calgary, Alberta

KEY SCOPE ELEMENTS

Feasibility Study | Tenant renovation | Condensed construction schedule | WELL Gold certified

City of Toronto

Nathan Phillips Square Spirit Garden

The City of Toronto has been revitalizing areas of the City’s landmark Nathan Phillips Square at New City Hall. As part of the improvements, a new Teaching, Learning, Sharing, and Healing space was designed and constructed to recognize and honour the experience of Indian Residential School Survivors.

The project consisted of upgrades to existing surfaces with all new landscaping, including a water feature, large sculpture and public building.

HH Angus’ scope of work included mechanical and electrical engineering, security systems consulting, IMIT design, and commissioning. Specifically, the scope featured a full technical audit and inventory report to document all infrastructure and equipment impacted by the project; power supply for new landscape and other LED lighting fixtures; connection of new area drainage to existing storm systems in the parking level; mechanical and electrical services for the new 450 ft2 Teaching Lodge; and design of security systems for public spaces and the Teaching Lodge.

HH Angus also developed and prepared a commissioning plan for all mechanical and electrical equipment being installed during the project.

One of the interesting challenges of this project was working with multiple stakeholders to ensure the vision of all parties for the project was addressed.

SERVICES

Mechanical Engineering | Electrical Engineering | IMIT

design | Security Design | Commissioning

PROJECT FEATURES

Heritage site | Teaching lodge | New landscaping | Surface and parking improvements | Upgraded

existing exterior infrastructure

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Technical audit | Inventory Report | Power supply | Connection to drainage area in underground parking level | M&E services for new teaching lodge | Design of security systems

Waypoint Centre for Mental Health Care

Chigamik Community Health Hub

Waypoint Chigamik Mental Health Centre is part of a redevelopment project and replaces two older facilities in use since the 1800s.

The challenges of this project included the requirement that the entire building be completely designed in one stage, rather than proceeding with design packages, plus delays in funding during the design process which resulted in a requirement for both a base building package and a fitout package.

To accomplish this, HH Angus coordinated two tender packages and two building permit submissions. Some detailed specifications in each package were interchangeable for the mechanical and electrical tender process. Working with phased schedules ensured that equipment start-up was fully coordinated between the tender packages.

The project faced additional challenges to provide an energy-efficient HVAC system, due to compliance with CSA Z317.2 and budget restrictions, as well as a small mechanical service space. To overcome these challenges, extensive coordination was implemented throughout the project across all disciplines.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design | ICAT Commissioning

PROJECT FEATURES

Size: 40,000 ft2 | DBFM | Fully ducted HVAC system designed to comply with CSA Z317.2 | Status: Completed 2020

LOCATION

Midland, Ontario

KEY SCOPE ELEMENTS

Building has full back up power with generator sized to accommodate the entire load of the building on loss of utility power conditions

Efficient design

Several engineering designs were reviewed by the project team to ensure compliance with the owner’s goals and restrictions, while achieving an efficient design.

Customized spaces

The two-storey 40,000 ft2 mental health care facility has amenities for indigenous smudging ceremonies, physiotherapy, conferences, a community kitchen, gathering rooms, and a youth programming space.

Renderings courtesy of Lett Architects Inc.

Confidential Client

Data Centre Campus (3 buildings)

The data centre campus is setting new standards for efficiency, significantly reducing energy consumption compared to the global average.

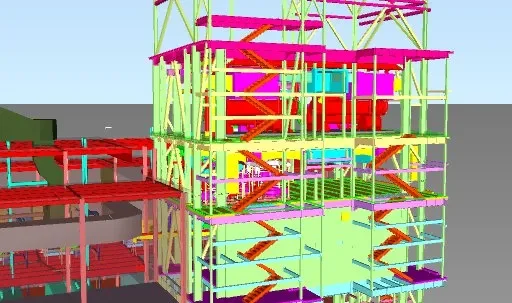

HH Angus was engaged to provide mechanical and electrical design and engineering services for the campus facility. Each of the three data centres is three storeys, and constructed with concrete slabs and structural steel. Continuous systems monitoring and secure DCIM controls will ensure optimal performance and reliability.

With three data centre buildings and one administrative building, ample space is provided for expansion, supported by adjacent access to a planned solar farm for sustainable energy supply. The data centre campus anticipates a combined capacity of approximately 100 - 125 MW.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

3 data centre buildings and 1 administrative building | Status: Ongoing

LOCATION

Western Europe

KEY SCOPE ELEMENTS

Comprehensive connectivity | Robust security | Advanced cooling systems (flexibility of having air cooled or liquid cooled installations for higher densities) | Redundant A+B side power distribution | N+1 redundancy in cooling, UPS and generators

Sustainability Features

Engineered to excel in a challenging climate, the data centre will leverage utility green energy programs, solar and wind power purchase agreements, and certified carbon credits. By embracing passive sustainable design practices, the design goal was to minimize environmental impact while delivering reliable and efficient data services for the client.

Proud Partnership

HH Angus has provided both recent and ongoing consulting engineering services to this client for additional data centre locations in Europe and the United States.

Enwave Energy Corporation

Pearl Street Energy Centre

The Pearl Street Energy Centre project has been honoured with an Award of Distinction at the Ontario Engineering Project Awards by the Association of Consulting Engineering Companies (ACEC).

Buildings in Toronto generate more than half of the city's greenhouse gas emissions. New technologies, like Enwave's expanded heat delivery system, will play a critical role in reducing our cumulative carbon footprint.

This project exemplifies cutting-edge engineering and design, integrating robust energy solutions that challenge traditional methods. Our focus on sustainable and efficient energy use through advanced engineering practices not only supports but advances the environmental goals of urban energy systems. HH Angus was the Prime Consultant and Mechanical and Electrical Design Engineers for the Pearl Street Energy Centre (PSEC) project. We also acted as the design team project managers.

When fully utilized, Enwave's low carbon heating facility will provide enough low-carbon heating to reduce emissions in Toronto by approximately 11,600 tCO2e, the equivalent of converting over 10 million square feet of office space to net zero.

As part of the TransformTO Climate Action Plan, which outlines ways to improve the city’s health, grow the economy and improve social equity, district energy was identified as a key strategy. In 2017, Enwave was selected as a partner by Toronto’s City Council to help accelerate the implementation of the plan to reduce greenhouse gas emissions and make the city more resilient.

Enwave’s district energy system is the largest in North America. It serves 180 buildings comprising more than 40 million square feet through 4 interconnected downtown plants and 40 kilometres of underground pipes. The addition of the PSEC to the district energy system will expand Toronto’s district heating and cooling distribution and capacity using low carbon technologies, by installing 3600 tons of cooling and 62,000 Mbh (thousand BTU’s per hour) of heating using water source heat pumps (heat reclaim chillers). Enwave’s ‘Green Heat’ offering is also being made possible by the installation of new assets that utilize waste heat while producing cooling and hot water.

The site offered some interesting complexities to be solved by the design team. The first was space constraints. As the existing Energy Centre did not have any space to house the new equipment, the only available space that could be used for the addition is a small corner on the lot where buried fuel oil tanks are present. A design was implemented to build over the tanks, one that would comply with the requirements of the Ontario Building Code and the Technical Standards and Safety Authority by leaving the ground level open for future removal of the tanks. All disciplines had to overcome many challenges due to space limitations, including structural, architectural, mechanical, and electrical.

A challenge for the mechanical design team centered on how to integrate the new heat pump system with the existing heating and cooling district system, as well as how to stage equipment without impacting Enwave’s existing customers and their stringent temperature requirements. Our solution was to design a false loading system to start and stage on additional heat pumps in order to avoid temperature spikes which would have negative impacts on customers’ critical data centre equipment.

According to the Canada Green Building Council, “it’s estimated that residential, commercial, and institutional buildings contribute 17% of Canada's greenhouse gas emissions today, and when building materials and construction are included, this level approaches 30%”. As the designers and engineers of these facilities, the AEC industry has an outsize role to play in ensuring the success of sustainable development.

HH Angus has a proven track record of promoting innovative and sustainable engineering solutions. We are committed to providing engineering solutions that reduce energy consumption and reduce or eliminate greenhouse gases.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Completed 2025 | New assets use waste heat while producing cooling and hot water | 3600 tons of cooling | 62,000 Mbh heating using water source heat pumps

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Overcame site constraints through innovative design to comply with OBC and TSSA requirements | Integrated new heat pump system to existing system