Service: Prime Consultant

Opercule Urban Fish Farm

The Opercule Fish Farm project is a pioneering initiative in the heart of Montreal, representing the first urban fish farm in Canada. This innovative project is based on a unique approach to fresh fish production, combining cutting-edge technology, respect for the environment and a local supply network.

Opercule annually raises 25 to 30 tonnes of Arctic Char, a fish species highly prized by Montreal restaurants and residents, and raised without the use of chemicals, hormones or antibiotics.

The primary goal for the Opercule Fish Farm was to create an eco-friendly, sustainable fish farm with a low impact on the environment and providing excellent living conditions for fish. HH Angus worked closely with the client to understand their unique and ground-breaking vision and was able to design innovative solutions tailored to this one-of-a-kind project. The project’s design also stands out for its ability to produce fresh fish locally in a non-coastal city.

This model of aquatic urbanism fits perfectly into a context where demand for local, sustainable products is growing. Working with the HH Angus design and engineering team, Opercule is meeting Montreal’s appetite for Arctic Char by supplying top-quality fish while reducing the usual carbon footprint associated with transporting seafood from coastal regions.

The project's innovative design and short-supply chain production model allow Opercule to raise high-quality fish in an urban environment in response to a growing local demand for sustainable food products. Fish swimming in the morning can be on diners’ plates the same evening, frequently delivered to restaurants by e-bikes to further reduce the product’s carbon footprint.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Canada’s first urban commercial fish farm | Sustainable production processes | Reduced carbon footprint compared to traditional fish farming methods | Closed circuit production loop

LOCATION

Montréal, Quebec

KEY SCOPE ELEMENTS

Design and engineering to enable production of food fish in a dense urban environment, utilizing municipal services infrastructure| Production of technical reports for provincial Authorities Having Jurisdiction, due to uniqueness of the project | Custom design solutions to respond to changing operational conditions

Enabling production at scale

No design references or construction expertise existed for this pioneering enterprise, and the client placed their trust in HH Angus’ ingenuity and adaptability to deliver the vision.

The project’s key technical innovation was the development of the Recirculating Aquaculture System (RAS) system - the first of its kind in Quebec - which allows fish to be produced in a closed circuit, from egg to table.

From the outset, we worked very closely with Opercule to thoroughly understand the challenges and goals. The client had a strong vision for their new company, were deeply committed to its success, and actively involved in the project’s technical aspects. One of the owners brought a background in consulting engineering, and this made our collaboration highly productive.

Reducing environmental impact

The primary goal for Opercule was to create an eco-friendly, sustainable fish farm with a low impact on the environment and providing excellent living conditions for fish.

The RAS process is a sustainable model that significantly reduces the environmental footprint of the operation by reducing not only water but alsoenergy consumption compared to traditional aquaculture. The system minimizes the use of these precious resources, a crucial factor in an urban environment. By recovering, filtering and reusing water, the farm significantly reduces water consumption compared to traditional fish farming methods, which are often very water intensive. The system allows the company to reduce water consumption by 100 – 200 times compared to traditional systems.

In terms of waste management, Opercule uses environmentally friendly techniques to treat the organic and biological waste generated by production, helping to reduce overall environmental impact. The project also promotes use of sustainable materials for the construction and fitout of the facilities, reducing the carbon footprint of the entire system.

In addition, the absence of chemicals, hormones and antibiotics in fish production ensures no soil or water contamination. This approach helps preserve local ecosystems and eliminates the risk of pollution.

Engineering design challenges

The complexity of the Opercule project stems from a number of technical and logistical factors. The creation of an urban fish farm requires a completely unique design adapted to a dense urban environment. The design of a water recirculation system, intended to ensure the well-being of the product from the egg stage to the delivery of the fish, required the development and refinement of innovative technologies in filtration, nutrient management, and optimization of living conditions in confined environments.

Challenges included managing water quality, which is essential for fish health, as well as creating an optimal environment for rearing Arctic Char, known to be a delicate species. This challenge involved the creation of autonomous systems to maintain constant temperatures and pH levels, without the need for chemical treatments. In addition, bio-safety management was a priority to avoid contamination.

During the operational phase, it was discovered that the heat generated by the fish—even though they are cold-blooded—had been underestimated. This required adjustments to operational conditions to maintain stable water temperatures. Despite this challenge, our close collaboration with the client ensured these modifications were implemented effectively, showcasing the team’s problem-solving abilities.

Sunnybrook Health Sciences Centre

Space Optimization Study Using AWS QuickSight

Sunnybrook Health Sciences Centre, a leading healthcare provider in Toronto, was seeking to address challenges in medical space utilization. With a diverse array of clinical services and bookable exam rooms, Sunnybrook faced challenges understanding a perceived shortage of space. Yet, intermittent observations suggested that many exam rooms were frequently empty.

M6 – Multipurpose Clinical Space | Yuval & Lori Barzakay Brain Health Clinic Study

To gain a clearer understanding of space utilization and identify potential inefficiencies, Sunnybrook partnered with HH Angus, leveraging our expertise in digital solutions and innovative engineering. The goal was to implement a robust monitoring system to capture accurate data on room usage, enabling informed decisions on resource allocation.

This project reflects Sunnybrook’s commitment to operational efficiency, ensuring that resources are optimally allocated to improve patient care and support staff needs.

SERVICES

Prime Consultant

PROJECT FEATURES

Digital monitoring system to inform clinical resource allocation | Enhanced operational efficiency | Patient privacy | Scalable design | Predictive analytics

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Space utilization measurement and analysis | Data acquisition through sensor deployment | Security and connectivity | Data aggregation and storage | Visualization and insights

Solving Space Utilization Challenges

Sunnybrook’s medical staff expressed concerns about limited space availability, particularly for bookable exam rooms. However, casual observations indicated that some rooms appeared to remain empty. Sunnybrook needed a reliable solution to measure actual room usage accurately while addressing two significant concerns:

Privacy: Ensuring patient privacy was paramount, particularly in sensitive clinical settings.

Accurate Detection: Existing solutions struggled to detect minimal motion, such as during procedures like blood transfusions, where patients may remain largely still.

HH Angus was engaged to design and implement a solution capable of addressing these challenges while delivering actionable insights.

Solution | Smart Sensors and AWS Integration

Our Digital Services team developed an innovative solution leveraging cutting-edge sensors and AWS services:

Sensor Deployment:

-

- mmWave Sensors: Initial deployment involved mmWave sensors capable of detecting micro-motions, such as breathing, to confirm room occupancy. These sensors were equipped with cellular SIM cards to operate independently of Sunnybrook’s network.

- 3D Stereoptic Sensors: To further expand the data gathered from the various clinics, the move to 3D-stereoptic sensors was used to provide not just occupancy status of exam rooms, but also the near real-time occupancy count data. Enhancing scalability, these sensors could monitor multiple rooms simultaneously, offering greater hardware efficiency.

Security and Connectivity:

-

- mmWave sensors utilized mTLS (mutual Transport Layer Security) for secure data transmission.

- Custom authorization for 3D-stereoptic sensors was implemented using AWS Lambda.

Data Aggregation and Storage:

-

- Data was streamed via Amazon Data Firehose and AWS IoT Core, stored in AWS S3, and processed through AWS Lambda.

- A centralized S3 data lake provided a secure, scalable repository for all processed data.

Visualization and Insights:

-

- Data queries were conducted using AWS Athena, while AWS QuickSight offered intuitive 2D dashboards for near-real-time analysis with minimal latency.

This comprehensive approach ensured seamless integration, robust data security, and actionable insights for Sunnybrook.

Outcome | Actionable Insights and Future Expansion

The solution provided Sunnybrook with detailed, data-driven insights into space utilization:

Initial Findings: The installation was completed in December 2024, and data collection began in January 2025. Analysis of the 11 monitored exam rooms in Sunnybrook’s M-Wing, conducted from January to March 2025, revealed a surprising utilization rate of only 33%. This insight challenged initial staff assumptions and highlighted opportunities for more efficient space planning.

Future Outlook: New medical clinics, which opened in January 2025, will contribute additional data to further refine Sunnybrook’s understanding of space usage and inform future expansion strategies.

Through this project, Sunnybrook is well-positioned to optimize its clinical spaces, ensuring that resources are allocated effectively to enhance both staff workflows and patient care delivery.

Key Outcomes Summary

Accurate Space Utilization Data: Revealed underutilization of monitored exam rooms, providing actionable insights.

Efficient Resource Allocation: Enabled informed decisions about space planning and allocation.

Scalability: Designed for expansion, with sensors deployed to additional clinics.

Improved Patient Care: Enhanced operational efficiency supports better patient care delivery.

Predictive Analytics: Tool for staff to forecast resourcing needs based on the day of the week using historical trends

Privacy Assurance: Leveraged secure sensor technologies to maintain patient confidentiality.

AWS Services Used

AWS S3 (Simple Storage Service): Acted as the central repository for storing and

retrieving large datasets, facilitating data analysis and accessibility.

AWS IoT Core: Enabled secure, scalable connectivity for IoT devices, allowing for efficient data collection and integration into the cloud.

AWS Athena: Offered an interactive query service to analyze data in Amazon S3 using SQL, simplifying the extraction of actionable insights from complex datasets.

AWS QuickSight: Provided visualization tools and dashboards for business intelligence, enabling Manulife to derive and act upon insights from their data effectively.AWS Lambda: Supported serverless computing, automating data processing and transformation tasks without the need for server management.

Amazon Data Firehose: Streamlined the capture, transformation, and loading of streaming data, ensuring efficient data flow from IoT devices to storage and analysis tools.

AWS IoT Events: Monitored sensor data for specific conditions, facilitating real-time alerting and response mechanisms to optimize building operations.

AWS Step Functions: Orchestrated complex data processing workflows, coordinating the various components of the ETL pipeline for streamlined operation and maintenance.

Enwave Energy Corporation

Pearl Street Energy Centre

The Pearl Street Energy Centre project has been honoured with an Award of Distinction at the Ontario Engineering Project Awards by the Association of Consulting Engineering Companies (ACEC).

Buildings in Toronto generate more than half of the city's greenhouse gas emissions. New technologies, like Enwave's expanded heat delivery system, will play a critical role in reducing our cumulative carbon footprint.

This project exemplifies cutting-edge engineering and design, integrating robust energy solutions that challenge traditional methods. Our focus on sustainable and efficient energy use through advanced engineering practices not only supports but advances the environmental goals of urban energy systems. HH Angus was the Prime Consultant and Mechanical and Electrical Design Engineers for the Pearl Street Energy Centre (PSEC) project. We also acted as the design team project managers.

When fully utilized, Enwave's low carbon heating facility will provide enough low-carbon heating to reduce emissions in Toronto by approximately 11,600 tCO2e, the equivalent of converting over 10 million square feet of office space to net zero.

As part of the TransformTO Climate Action Plan, which outlines ways to improve the city’s health, grow the economy and improve social equity, district energy was identified as a key strategy. In 2017, Enwave was selected as a partner by Toronto’s City Council to help accelerate the implementation of the plan to reduce greenhouse gas emissions and make the city more resilient.

Enwave’s district energy system is the largest in North America. It serves 180 buildings comprising more than 40 million square feet through 4 interconnected downtown plants and 40 kilometres of underground pipes. The addition of the PSEC to the district energy system will expand Toronto’s district heating and cooling distribution and capacity using low carbon technologies, by installing 3600 tons of cooling and 62,000 Mbh (thousand BTU’s per hour) of heating using water source heat pumps (heat reclaim chillers). Enwave’s ‘Green Heat’ offering is also being made possible by the installation of new assets that utilize waste heat while producing cooling and hot water.

The site offered some interesting complexities to be solved by the design team. The first was space constraints. As the existing Energy Centre did not have any space to house the new equipment, the only available space that could be used for the addition is a small corner on the lot where buried fuel oil tanks are present. A design was implemented to build over the tanks, one that would comply with the requirements of the Ontario Building Code and the Technical Standards and Safety Authority by leaving the ground level open for future removal of the tanks. All disciplines had to overcome many challenges due to space limitations, including structural, architectural, mechanical, and electrical.

A challenge for the mechanical design team centered on how to integrate the new heat pump system with the existing heating and cooling district system, as well as how to stage equipment without impacting Enwave’s existing customers and their stringent temperature requirements. Our solution was to design a false loading system to start and stage on additional heat pumps in order to avoid temperature spikes which would have negative impacts on customers’ critical data centre equipment.

According to the Canada Green Building Council, “it’s estimated that residential, commercial, and institutional buildings contribute 17% of Canada's greenhouse gas emissions today, and when building materials and construction are included, this level approaches 30%”. As the designers and engineers of these facilities, the AEC industry has an outsize role to play in ensuring the success of sustainable development.

HH Angus has a proven track record of promoting innovative and sustainable engineering solutions. We are committed to providing engineering solutions that reduce energy consumption and reduce or eliminate greenhouse gases.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Completed 2025 | New assets use waste heat while producing cooling and hot water | 3600 tons of cooling | 62,000 Mbh heating using water source heat pumps

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Overcame site constraints through innovative design to comply with OBC and TSSA requirements | Integrated new heat pump system to existing system

Lonsdale Energy Corporation

Heat Recovery Feasibility Study

HH Angus conducted a study to evaluate the feasibility of exhaust air heat recovery from the Global Relay (GR) data centre facility at 22 Gostick Place in North Vancouver, BC.

Some of the key aspects of the study included:

- The location and footprint of the heat recovery system components were studied within the context of considerable site constraints. The study evaluated the design, construction, and cost considerations for the implementation of the proposed heat recovery system.

- We investigated available heat pump technologies that would be appropriate for recovering waste heat and would satisfy the LEC DES requirements.

- The energy recovered would be used by a water source heat pump to provide hot water to the local LEC District Energy System (DES).

- A water source heat pump system was proposed as the best solution to provide the ability to recover heat from the building ventilation system. The new system would recover heat from the GR facility and would transfer this recovered heat via a hot water loop to the local LEC DES.

- Heat recovery is feasible for the facility and can provide up to 1,100 kW of heating capacity to the LEC DES.

- Constraints to the design of the heat recovery system were also identified, and included:

(i) the quantity of air exhausted from the facility is not fixed and ranges at each exhaust plenum on a seasonal basis and depending on outdoor air temperature – this impacts how much heat can be recovered at a given time;

(ii) the minimum and maximum exhaust air temperatures range from 30°C to 43°C (86°F to 110°F) - the temperature of the exhaust air will influence how much heat can be recovered from the exhaust air; and,

(iii) the cross-sectional area available for the heat recovery coil - the more cross-sectional area that is available for a given amount of heat transfer, the less deep the coil must be (and less airside pressure drop penalty is incurred).

The study concluded that a purpose-built containerized heat pump system would be the most suitable solution to meet the needs of the project. This new containerized structure would be conveniently located adjacent to the GR facility and would exhibit the same architectural character as the existing facility. The proposed heat pump system would include one heat pump unit (based on Emerson Heat Pumps) and four heat recovery water pumps. Control valves, piping accessories, ventilation, lighting, and system controls would all be included in the proposed pre-fabricated containerized enclosure.

Outdoor hydronic piping would connect the heat pump enclosure to the GR facility and the proposed hydronic heat recovery coil system. The heat recovery coil system would consist of four new heat recovery coils placed within the existing facility exhaust air plenums. The existing exhaust fan motors would have to be upgraded in order to address the additional pressure drop introduced by the new heat recovery coils. This fan motor upgrade would also trigger upgrades to the existing electrical infrastructure.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: 5,600,000 ft2 | Status: Ongoing

LOCATION

Vancouver, British Columbia

KEY SCOPE ELEMENTS

Feasibility study | Heat recovery

Confidential Client

BIM Laser Scanning

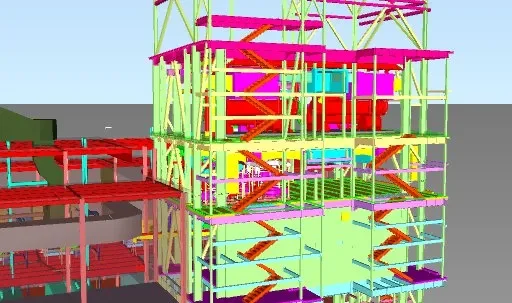

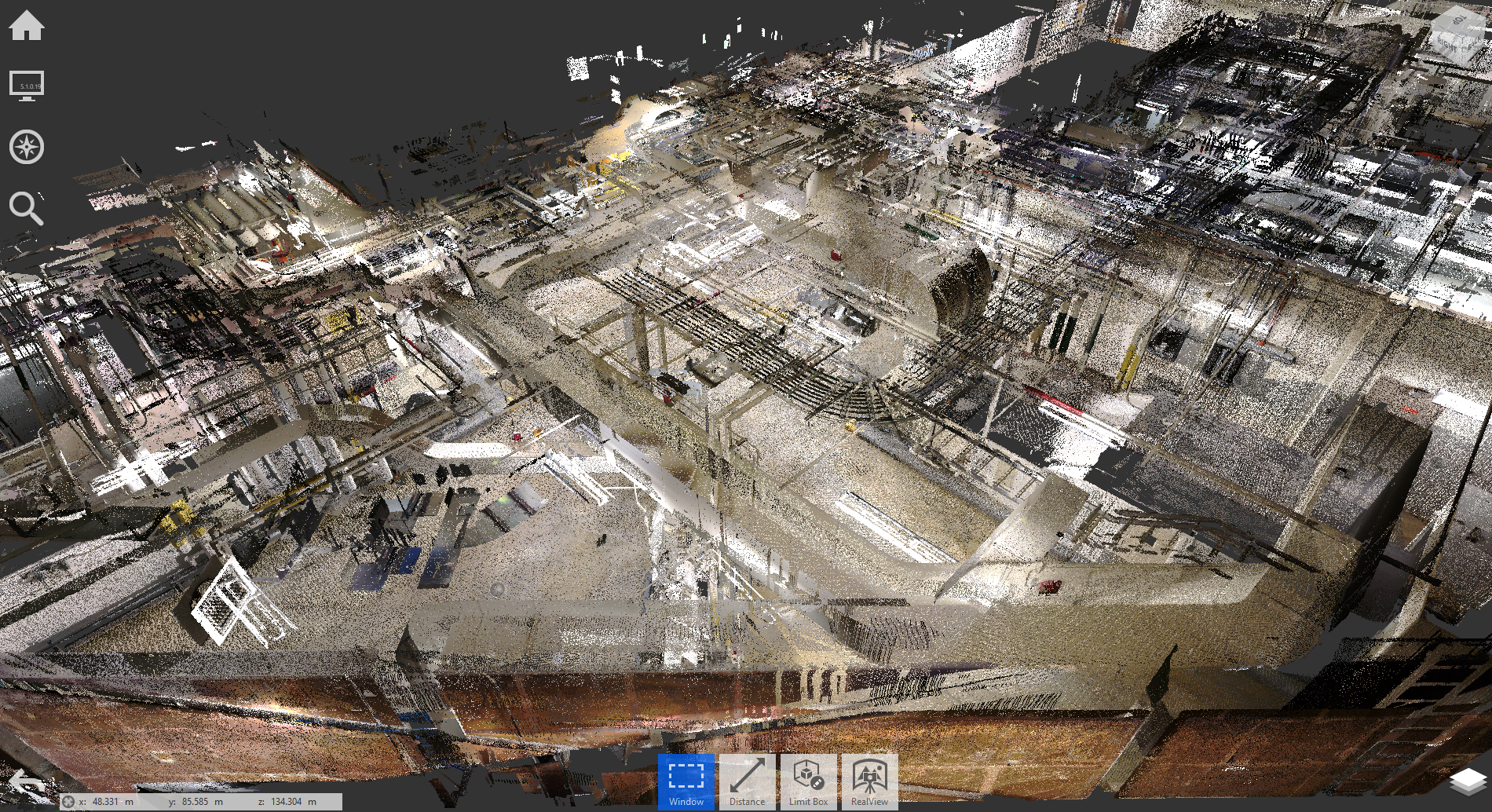

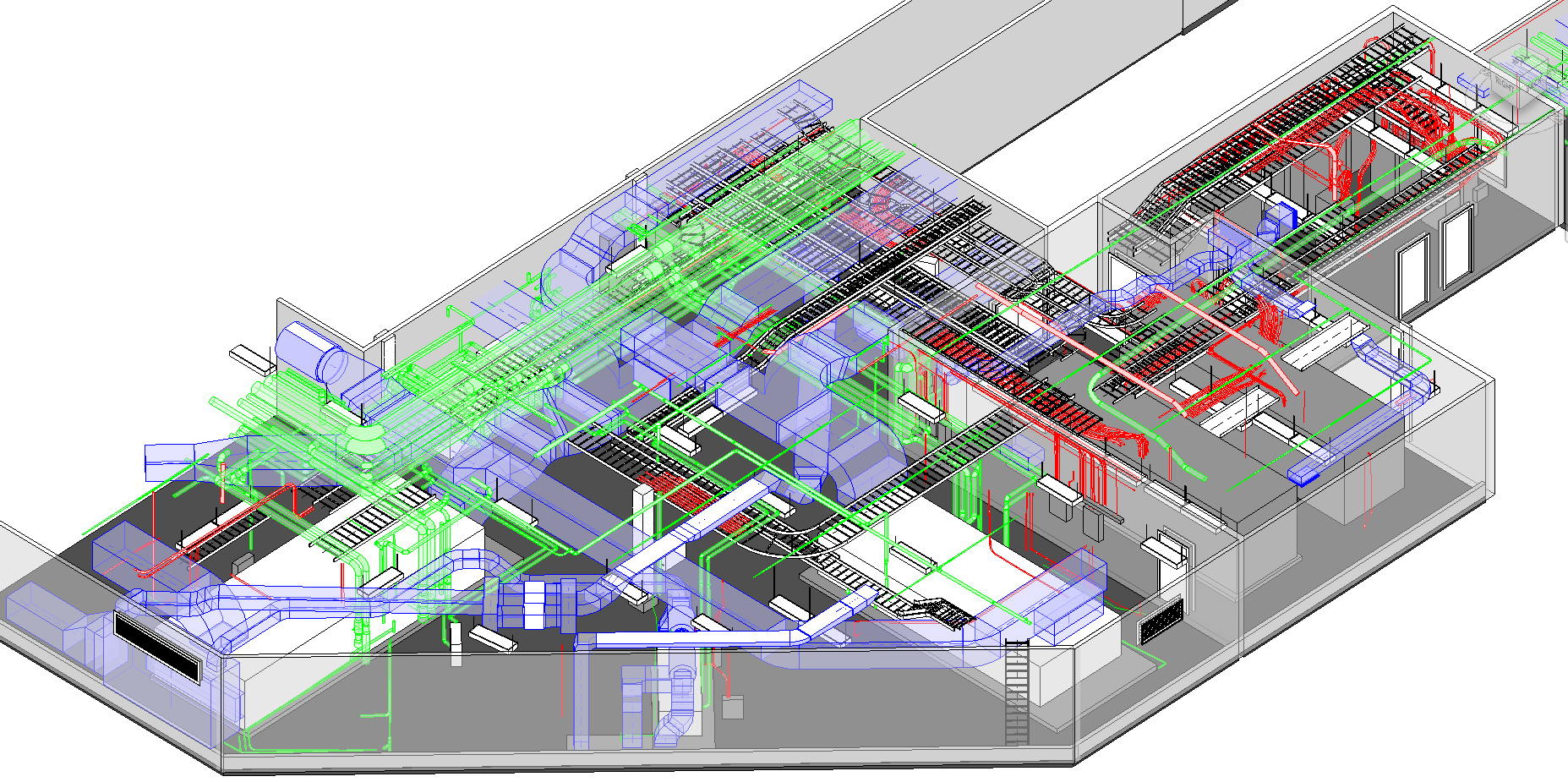

HH Angus was engaged to create a 3D Revit model (LOD 300), accurate to reality, of the existing structure and visible HVAC, plumbing and electrical infrastructure. This model was delivered to the client for their use in 3D coordination of their high voltage switchgear replacement project.

The 17,000 ft2 area was scanned using a Faro S70 Laser scanner, with the scans subsequently registered using Faro Scene software to create point clouds. Point clouds were then processed in Edgewise modeling software and used to automatically extract and model walls, structure, piping, conduit and ducts, before being imported into Revit. This efficient process resulted in a very significant 60% reduction in modeling time. The remaining MEP infrastructure was modeled in Revit, with special attention paid to the location of the entry and leave points within rooms for all MEP infrastructure, in response to the client’s requirement.

One of the challenges of the project was the lack of easily accessible data required to create the Revit model. Recap pro or Faro Scene software is needed to review the point clouds and images; this software required licensing and installation on individual machines, which prevented it from being easily accessible to everyone on the project team. The software also requires additional computing power to run smoothly, and this presented an issue for machines that did not meet the software requirements.

SERVICES

Prime Consultant | Scan to BIM provider

PROJECT FEATURES

Revit modeling of existing structure and visible HVAC, plumbing and electrical infrastructure

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

3D laser scanning