Service: Prime Consultant

CREIT

Bloor-Dundas District Energy Feasibility StudyHH Angus was engaged to conduct a feasibility study for a Low Carbon District Energy Plant serving a new, three million square foot mixed use residential and commercial development along Bloor Street in Toronto.

The full development is being implemented in several stages over ten years. HH Angus provided Prime Consultant and Mechanical and Electrical Engineering services, and developed a conceptual framework for the study.

The study considered a combination of traditional and renewable energy sources to provide heating and cooling, reviewing a range of options that included the following:

- Condensing hot water boilers, efficiency up to 90-95%

- Centrifugal water-cooled magnetic bearing chillers

- Water source heat pumps (heat recovery chillers) to provide simultaneous cooling and heating

- Air source heat pumps to provide simultaneous cooling and heating

- Ground source heat pump system

- Ambient loop system

- Sewer heat recovery system

- Combined Heat & Power (CHP) system to generate power using a gas-fired generator and to provide heat using waste engine heat, with overall generator efficiency up to 80%. CHP can be used as backup power source and to reduce energy cost during periods of peak cooling and electrical demand.

HH Angus conducted calculations of estimated heating, cooling and electrical loads, plus energy consumption for future development, establishing options for the arrangement of the District Energy plant, including provision for expansion to provide heating and cooling to future developments in the neighbourhood.

Our study scope also included tentative District Energy plant layout and area requirements, capital budget, operating costs and NPV estimates for each option, as well as analysis of results and corresponding recommendations.

SERVICES

Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Size: Low carbon district energy study | Due diligence engineering report | Status: Completed 2018

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Assessment of district energy plant designs to serve 3 million ft2 of mixed use development | Calculation of estimated heating, cooling and electrical loads and energy consumption for future development | Analysis of results and corresponding recommendations for optimal design | Consideration of traditional and renewable energy sources

Trillium Health Partners

Infrastructure Renewal

The infrastructure renewal work for Trillium Health Partners is focused on the Queensway Health Centre site, an acute care facility. Some of the funding comes from Ontario’s Healthcare Infrastructure Renewal Fund (HIRF), which supplements a hospital’s existing infrastructure renewal program and helps address renewal needs on a priority basis.

As prime consultant, HH Angus is implementing a series of mechanical and electrical infrastructure upgrades that include air handling units, Phase four of the electrical infrastructure renewal, as well as miscellaneous other projects. The scope of work includes the redesign of major mechanical and electrical infrastructure. Along the way, we are integrating newly designed systems into existing facilities, which presents some interesting challenges, given the age of the existing infrastructure.

A key consideration of the work is avoiding disruption to hospital services, and this is the paramount factor in scheduling. In order to ensure continued hospital operation, carefully planned sequential shutdowns minimize disruption to both staff and patients.

SERVICES

Prime Consultant | Electrical Engineering | Mechanical Engineering

PROJECT FEATURES

Status: Ongoing

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Series of mechanical and electrical infrastructure upgrades | Challenging renovation within old infrastructure | Hospital required 24/7 operations around planned shutdowns | Infrastructure Renewal Bundle 3 includes AHUs boiler modifications | Phase 4 electrical infrastructure renewal, roofing replacement, etc.

— Photos courtesy of Trillium Health Partners

Joseph Brant Hospital

Communications & Automation Technology (ICAT) Vision, Planning, Procurement

The ICAT strategy at Joseph Brant Hospital focused on the interoperability of services between the existing facility and the new facility to allow for seamless delivery of care across the campus.

Our project scope was to develop Joseph Brant Hospital’s (JBH) ICAT vision, and to assist with planning, procurement and implementation of the ICAT strategy. This project was aligned with the P3 procurement project of a new patient tower and renovations to the existing facility, approximately 500,000 ft2. The ICAT strategy included existing and new hospital information technology, communications and automation systems, including the wired and wireless network, RTLS, nurse call, security, etc., as well as peripheral IT device planning.

Our team took the project's leadership through strategic visioning sessions. We facilitated user groups to understand the operations and create the functional requirements, which were translated into technical requirements for ICAT and used to inform and develop the Output Specifications and Technical Specifications.

The team coordinated various funding sources through an Order of Magnitude Cost Estimate exercise to prioritize the ICAT solutions with alignment to the strategic plan. By doing so, the hospital was able to strategically balance its future vision with the organization’s capabilities to roll out an Implementation Roadmap.

SERVICES

Prime Consultant | ICAT

PROJECT FEATURES

Size: 500,000 ft2 | Status: Completed 2018

LOCATION

Burlington, Ontario

KEY SCOPE ELEMENTS

Strategic planning for ICAT | Implementation of road map | Integration concept and design | Design specifications for infrastructure systems

Leading change

One of the challenges of the project was for users to envision how emerging technologies would fit into their current workflows and processes. Our team used a Lean approach, walking through current state processes and challenging users to see best practices, and how ICAT systems would play a role in the future state.

Technology supports learning

As a future site for medical teaching, JBH is looking for opportunities to introduce technology to advance the education mandate. In addition, the hospital continues to look for ways to enable patient care beyond the walls of the facility, through use of the systems by remote staff or providing pre- and post-hospital support and services to patients.

Siemens Canada

Algonquin College Trigeneration Plant

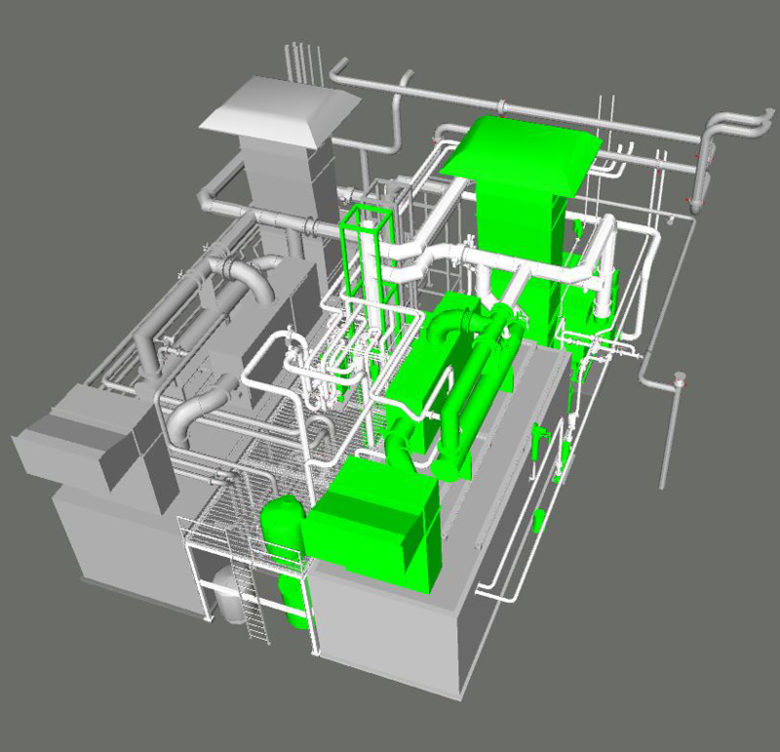

HH Angus was retained to design a trigeneration plant for Ottawa’s Algonquin College. Our scope included review of Siemens’ PSUI application to IESO, and assisting with their application. Because the existing central utility plant (CUP) was not large enough to accommodate new plant systems, our team developed a pre-engineered building to be built adjacent to the existing CUP.

As Prime Consultant, HH Angus retained Milman and Associates to undertake the required structural engineering, including a roof design to accommodate the cooling towers, rad cooler and transformer. An additional mezzanine was added to house auxiliary equipment.

In order to maximize the usable heat during summer months, a 350 ton absorption chiller, using double effect flue gas and hot water, was detailed. The 2 MW reciprocating trigeneration plant features selective catalytic reduction units and a heat recovery boiler.

Some project challenges included:

- Integrating and commissioning a trigeneration system into an operating facility

- Noise constraints due to proximity of CUP to College operations

- Space constraints due to pre-engineered building

- Footprint was maxed out based on site restrictions; HH Angus had to take into account future co-gen, chiller and ancillaries

- Ongoing upgrades in CUP heating and cooling, which HH Angus coordinated with another consultant

- Operating flexibility required for both parallel and island operation

- Solutions included: designed mezzanines in the existing CUP to house equipment and accommodate new, pre-engineered building for the second cogen and chiller; and rigorous scheduling coordination with Utility and College operations staff

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed 2017

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Review of PSUI application to IESO | 350-ton absorption chiller | 2 MW reciprocating trigen plant with selective catalytic reduction units & heat recovery boiler

Minimizing Disruption

All new equipment was connected to existing systems, with electrical connections restricted to well-planned shutdowns, resulting in minimal disruption to the ongoing operations of the campus.

Ericsson Canada

Global Information, Communications and Technology Centre

HH Angus served as Prime Consultant on Ericsson’s greenfield modular data centre testing facility in Montreal. This was one of three such sites for Ericsson oriented to telecommunications research and development; the first two in Sweden were operational in late 2014.

As Prime Consultant, HH Angus engaged and oversaw the structural engineers, civil engineers and architect, as well as the noise, vibration and air quality consultants.

The Centre, in Vaudreuil-Dorion, was built with modularity and scalability in mind, and to serve as the global facilities’ data centre.

Situated close to the firm’s R & D Hubs, the new facility was intended to connect 24,000+ Ericsson engineers worldwide, provide greater efficiency in research and development, and allow customers to connect remotely for testing interoperability in real time - for trials, early access, and new business services.

The Quebec site totalled 40,000 m2, of which 20,000 m2 was built out. The project included a 3530 m2 administration and support building. The company estimated that the combination of architecture, design and location would result in a significant reduction of 40% in energy consumption. Heat recovery strategies were implemented, such as waste process heat used to warm the building. In addition, a rainwater harvesting system provided water for both irrigation and process cooling.

One of the key challenges met on this project was managing communications. Four nations were involved (Canada, Sweden, the United States and the United Kingdom), and the team was spread over seven time zones, from Phoenix to Stockholm. While English was the working language of the project team, subgroups within it were variously working in Swedish, French and English.

SERVICES

Prime Consultants | Mechanical Engineering | Electrical Engineering | Plumbing | Fire Protection | Lighting | Communications | Vertical Transportation

PROJECT FEATURES

Size: 430,560 ft2 | Status: Completed 2016

LOCATION

Montréal, Quebec

KEY SCOPE ELEMENTS

Implemented innovative engineering and architecture design to reduce energy consumption by an estimated 40%