Service: Vertical Transportation

GO Transit

Erindale GO Station Parking Structure

The 6-level parking structure, on Rathburn Road West in Mississauga ON, provides 1,740 parking spaces for GO Transit patrons.

Engaged as the Vertical Transportation (VT) consultant on this project, a design-build led by Kenaidan Contracting, HH Angus was responsible for overseeing the team’s effort in the development of vertical transportation system requirements. These included design coordination, tender and eventual participation in shop drawing reviews, progress field reviews, and acceptance services, with support from other direct report team members. HH Angus coordinated all stages of the VT work to ensure appropriate quality control standards were maintained through all phases of the project, and identified related work requirements associated with the elevating devices, permitting coordination of these with the remaining Design Team disciplines.

Six machine room less (MRL) traction elevators were provided - four in the Parking Garage, and two additional units serving the elevated pedestrian bridge connection down to track level.

SERVICES

Vertical Transportation Consulting

PROJECT FEATURES

Award winning project | 6 storey parking structure | 6 machine room less traction elevators | Status: Completed 2014

LOCATION

Erindale (Greater Toronto), Ontario

KEY SCOPE ELEMENTS

Development of vertical transportation system requirements | Identification of work requirements associated with elevating devices

Award-winning project

The project was honoured with the 2014 International Parking Institute’s (IPI) Award of Merit and the 2014 City of Mississauga Urban Design Award of Merit.

Images courtesy of Kenaidan Contracting Ltd.

Canadian War Museum

The Canadian War Museum is a unique and historically important project, with a signature design appropriate to its purpose. Situated on Ottawa’s LeBreton Flats, on the bank of the Ottawa River, this world-class facility is a major attraction for Canadian and international visitors.

Inspired by countless acts of Canadian bravery in conflict zones around the world, Architect Raymond Moriyama created a design which blends seamlessly into the surrounding landscape. The building features a landscaped roof - low-maintenance, self-seeding, and fully accessible. The Memorial Hall is strategically located at the intersection of two axes. One aligns the Memorial with the Parliament Building’s Peace Tower, and the other is the solar azimuth at precisely 11:00 am on November 11 - Remembrance Day - when 11 precisely-oriented rods capture the sun’s rays at that poignant moment for Canadians, symbolizing spiritual rejuvenation and a new beginning.

The vertical transportation system includes five (5) passenger elevators and one (1) freight elevator to accommodate movement of large artifacts.

The elevator system design for this project required that special consideration be given to the site location and its geological characteristics. All elevators are of the “holeless” hydraulic type, with special design features to attain the travel distances required, within very tight overhead allowances.

The Canadian war museum is an affiliate of the Canadian Museum of Civilization and houses 440,000 ft2 of exhibit, archive and office space, as well as a 4,200 ft2 theatre.

SERVICES

Vertical Transportation Consulting

PROJECT FEATURES

Status: Completed 2002

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Elevator Design | 5 passenger elevators and 1 freight elevator

Tecnológico de Monterrey, Mexico

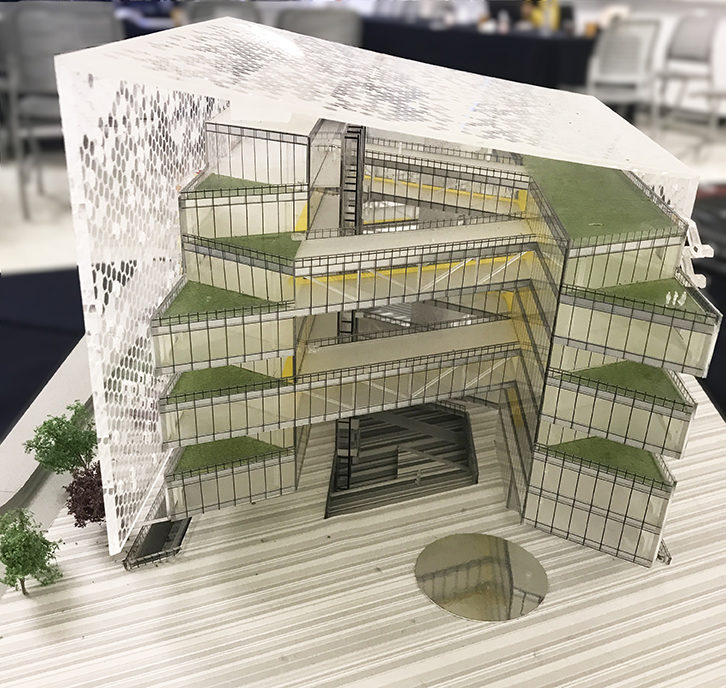

TecNano Academic BuildingTecNano is a proposed new academic building that combines a variety of lab spaces containing co-working environments. The intent is to support a highly interactive and collaborative research experience within the biotech lab building.

Tecnológico de Monterrey is a multi-campus private university in Monterrey, Mexico. The university has grown to 36 campuses throughout Mexico, with the Monterrey campus serving as its flagship institution.

HH Angus was engaged to provide ICAT (information, communications and automation technology) design services for a proposed new building, the TecNano Academic Building. The IT design scope included a main data centre with a subsidiary data centre dedicated to Multiomics. The IT design was based on a stacked central riser, with main and redundant facility entrances from the street and from the rear, connecting to the campus backbone. Wi-Fi would be available throughout the building, with lab benches and overhead carriers providing wired data connections.

The building design required an innovative solution to locating the IT backbone. We designed a riser in the exterior channel up the north side of the building to facilitate the open-air atrium as well as a stacked riser.

The security scope included access control, CCTV, duress alarms, and a central guard station with CCTV monitoring. The facility was designed with medium to high security measures, and featured dual factor credentials for specific lab entrances. There was one clean room with anteroom, and several isolation and pressurized anteroom labs, all requiring interlock and high-speed overhead doors.

Physical security also presented challenges. Intended to be welcoming, safe and secure, the facility was designed to be open to the campus on the North side and to act as a gateway to the campus from the street on the South side. We provided glass high-speed entrance portals for entrance circulation. The solution also had to function well in Monterrey’s extreme environment. Working with the architect, we provided a safe, secure, and high-speed portal that would be protected from the elements by the atrium ceiling high overhead.

The AV systems included a public auditorium with distance learning and lecture capture, video conferencing-enabled faculty boardroom, as well as AV-enabled student meeting, study, and huddle spaces. Digital signage in IP-65 enclosures provided wayfinding at the entrance for the facility and campus

The TecNano Academic Building laboratory types included:

Nanophotonics

Molecular Simulation

Metallomics

Advanced Optical Microscopy

Nanostructure Synthesis

Micro and Nanofabrication

Multiscale Manufacturing

Materials Characterization

Synthetic Biology

High Throughput Bioprocesses

Microrobotics

Tissue Engineering and Bioprinting.

SERVICES

ICAT Consultant - Security, Audiovisual and Communication Design

PROJECT FEATURES

Size: 25,500 m2 | Status: Design Completion 2018

LOCATION

Monterrey, Mexico

KEY SCOPE ELEMENTS

Biotech laboratory building, including clean room and nanotechnology labs | International collaboration – Client in Mexico, Architect in United States, ICAT and Vertical Transportation consultants in Canada

Innovative solutions

An interesting challenge affected the communications design, specifically the outside plant design. When the local municipality rejected street closures to install a communications duct bank for carrier entrance cabling, we surveyed the site, the facilities, and routing together with TecNanao IT, and designed a campus-internal route to meet the carriers’ entrance to the East. While it is a much longer route, it is also simpler to permit, as it was not located within the municipal right-of-way.

Image credits: FGP Atelier

Toronto Transit Commission

Easier Access Program - Subway Station UpgradesThe TTC’s ongoing Easier Access (EA) Program is making public transit more accessible for customers. The entire subway train fleet is accessible, and more than half of Toronto’s subway stations are wheelchair and scooter friendly.

HH Angus has been providing vertical transportation consulting and mechanical and electrical engineering to the TTC since 2010, as the transit system implements EA accessibility upgrades. This involves the design and construction of new elevator systems, as well as changes to the electrical and mechanical systems needed to accommodate the addition of EA upgrades across the subway system.

At the Wellesley Station, for example, two new elevators have been added. The work to support this upgrade included hydraulic, electrical, mechanical, structural and architectural components, along with the detailed project coordination aspects related to renovations.

Some of the challenges associated with the EA renovations include emphasis on limiting space requirements for new subsoil structures, reduced encroachment on property lines, reduced access limits for new equipment installations, relocation of existing services, and routing of new services through very confined and limited space, all requiring very specific, detailed and well-coordinated design.

Detailed coordination between all disciplines regarding all aspects of the project must be part of the design phase to minimize the potential for contractor-claimed extras during construction. For example, quick turnaround times for construction support activities must be adhered to, in order to achieve the construction schedule.

Some of the key success factors in EA upgrade projects include:

- Thorough site investigations prior to design to confirm all as built information. This is critical to determining where new services will be located and connected to existing services, in order to avoid any interference with those services, and to identify where relocation of existing equipment may be required.

- Close coordination between all disciplines to ensure a) the responsibilities of all project team members are clearly defined, and b) that the design is fully buildable without additional unknown factors; for example, avoiding issues that can arise from incomplete or outdated as built drawings.

-Having all stakeholders review the design, with all comments being addressed prior to Issued for Bid stages.

Over twenty subway stations are already complete or currently have upgrades in design or construction:

Union | St. George | Pioneer Village | Kennedy | St. Clair West | Queen | Bay | Ossington | Lansdowne | Museum | Lawrence | Yorkdale | Yonge/Bloor | Finch West | Kipling | Warden | Bathurst | Jane | Sherbourne | Wellesley | Christie | Keele | Rosedale | Chester

SERVICES

Vertical Transportation | Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Status: Ongoing system-wide upgrades for subway stations to provide accessibility | Mechanical, electrical and lighting system renovations and upgrades to support vertical transportation installations

LOCATION

Greater Toronto, Ontario

KEY SCOPE ELEMENTS

Design Build | Work within confined and limited space | Rapid turnaround on construction activities support to achieve schedule

Space constraints

Because space for EA projects is very limited and within a confined area, all construction details must be effectively designed to ensure constructability.

Bermuda International Airport

Redevelopment and New Terminal

The L.F. Wade International airport is the world’s gateway to Bermuda, and the redevelopment of its existing Passenger Terminal Building (PTB) was a high priority for the small island country. Because the current terminal is prone to flooding, it is susceptible to damage from major Atlantic storms, which could seriously impact Bermuda’s vital tourism industry.

The PTB redevelopment was undertaken as a P3 project. HH Angus provided mechanical engineering and vertical transportation design for all systems serving the airside and the PTB, working with a local affiliate to deliver contract administration services during construction.

The vertical transportation scope for the project included five new machine-room-less (MRL) traction passenger elevators and four escalators.

Some of the interesting challenges of the project included its profile as an international project on an island; adapting to local authorities having jurisdiction; resistance to hurricanes; flood mitigation; and the island’s water strategy–Bermuda's building code requires that all rainwater be captured and re-used, and the new PTB represents the largest roof area in the country. Also, salt-laden air and accelerated corrosion require the use of non-traditional materials as compared, for example, to similar buildings in Canada.

Among the features of the engineering design, the high water table easily allowed for geo-thermal heat rejection for the cooling plant.

SERVICES

Mechanical Engineering | Vertical Transportation

PROJECT FEATURES

Size: 2,886,902 ft2 (26,820 m2) | Status: Completion 2020

LOCATION

St. George's, Bermuda

KEY SCOPE ELEMENTS

Five new machine-room-less (MRL) traction passenger elevators and four escalators | Innovative mechanical design | Geothermal heat rejection for cooling plant | Mandated rainwater reuse for largest roof area in the country

Innovation and Excellence Award

The Bermuda airport project was awarded a 2021 Gold Award for Innovation and Excellence in P3s, from the Canadian Council for Public-Private Partnerships. It is only the second international project recognized by the

CCPPP in its history.

— Renderings courtesy of Scott Associates Architects Inc.