Service: Sustainability

Ontario University – Confidential

BESS & Microgrid System

The battery energy storage system facility reduces electrical demand for a Class A electricity facility operating during anticipated Global Adjustment hours.

Johnson Controls, the turnkey EPC and facility energy service company, engaged HH Angus to engineer a 2 MWe (4 MWh) behind-the-meter battery energy storage system (BESS).

The installation is part of a microgrid design that incorporates rooftop solar panels for six buildings (~500kWe), a 2 MWe (4 MWh) BESS, and a 2 MWe natural gas engine-generator peaker. The goal of the installation is to reduce Global Adjustment charges. It also supports much of the facility in the event of a power failure on the grid.

The solar panels and BESS were installed during spring and summer of 2018, and the engine-generator peaker plant has been submitted for a building permit.

SERVICES

Prime Consultant | Electrical Engineering

PROJECT FEATURES

Status: Completed 2021

LOCATION

Ontario

KEY SCOPE ELEMENTS

Engineered 2 MWe (4MWh) behind-the-meter battery energy storage | Microgrid design including solar, BESS, NG engine- generator peaking plant for six buildings

Energy innovation funding

The project was predicated on receiving Government of Canada Strategic Innovation Fund support for innovative energy projects.

Ontario College of Art & Design University

Professional Gallery

The OCAD Gallery is the flagship professional gallery for the Ontario College of Art and Design, Canada’s largest and oldest educational institution for art and design. It serves as an experimental curatorial platform for art, design and new media.

HH Angus was tasked with the mechanical, electrical and lighting design for this 755 m2/8,200 ft2 facility. It includes gallery space, a media lounge, permanent art collection and storage, administration support services and shipping and receiving areas.

This project provided interesting design challenges to protect the art from potential water leakage from the tenants on the floor above. The ceiling is covered in a white waterproof membrane, which made recessed luminaires impractical.

The ceiling beams have a dual purpose – to support the track luminaires and to create an artistic industrial feel for the space. The track is two circuit to allow for maximum flexibility. LED track heads are 3500K with a CRI above 93 to enhance the colour of artwork in the exhibits. The track heads were chosen to allow for multiple and varied beams spreads, to enhance each exhibit and to provide flexibility by accommodating different lensing and media. Suspended linear LED luminaires were used in non-gallery spaces. Various power and data systems were used throughout the premises.

The heating and ventilation systems were designed to meet the mechanical requirements for a Class ‘A’ Art Gallery. The mechanical requirements for the Gallery consist of controlled humidification levels and temperature range. To achieve the requirements, a separate dedicated standalone mechanical air conditioning/humidification system was designed for the space. An indoor dry cooler and a series of heat pumps are located throughout the facility. Each heat pump has an associated electric humidifier and associated condensate pumps.

SERVICES

Mechanical Engineering | Electrical Engineering | Lighting Design

PROJECT FEATURES

Size: 8,200 ft2 | Status: Completed 2017

LOCATION

Toronto, Ontario

KEY SCOPE ELEMENTS

Water leakage mitigation | LED luminaires | Power and data systems | Controlled humidification | Heating and ventilation systems for Class A Art Gallery standard

Meeting Project Goals

The OCAD project was delivered under budget and met LEED certification requirements.

Custom Lighting Requirements

A central dimmable lighting control system was incorporated. The lighting control was divided into multiple zones to satisfy the custom needs of the Gallery.

Public Works & Government Services Canada

Tunney’s Pasture

HH Angus was engaged as Prime Consultant on a chiller plant installation for this public building in Ottawa. The project installation serviced nineteen buildings with a total floor space of ~3,170,000 ft2 and was comprised of two chillers @3500 tons.

Tunney’s Pasture is a 49-hectare (121 acre) mixed-use campus in Ottawa, including government services, commercial offices and residential buildings. Its existing steam-driven chillers were at end of life and operating with R22 refrigerant, the import and production of which is banned as of January 2020. Also, the use of river water for free cooling needed improvement and the river water pumping system was not operating efficiently.

HH Angus, in joint venture with Goodkey Weedmark, was retained to undertake conceptual studies to evaluate changing the chillers from steam power to electrical power. We also made recommendations for improving the free cooling aspects of river water and making more effective use of the river water pumping system.

HH Angus provided conceptual evaluation of replacing the chillers, in terms of efficiency, physical location and necessary steps required to change from steam to electrical power. Once the chiller concept was resolved, we evaluated optimization of the river water pumps to undertake the condenser water cooling and considered how to efficiently use the free cooling available from the river in low load conditions.

Optimizing free cooling and condenser water, using river water instead of cooling towers, resulted in energy efficiency and reduced carbon footprint for this installation. We also identified benefits to the client through improvement in chiller efficiency using the latest technology, and the elimination of boiler operation during the summer months.

SERVICES

Prime Consultant | Mechanical Engineering | Electrical Engineering

PROJECT FEATURES

Status: Completed: 2017

LOCATION

Ottawa, Ontario

KEY SCOPE ELEMENTS

Evaluation to optimize river water pumps to undertake condenser water cooling & efficient use of free cooling from the river in low load conditions | Consulted on technology that would eliminate boiler operations during summer months

Durham Region Transit

Oshawa Bus Maintenance Facility

Durham Region needed to accommodate the repair/maintenance requirements of its fleet of buses with a facility that would be integrated into an existing building. The project is on track for LEED® Silver Certification.

The project features a state-of-the-art Transit Control Centre on the second floor for regional bus and GTAA connection communications. Highlights include state-of-the-art ventilation and exhaust systems, fuel/fluid dispensing, a vacuum cleaning system, parts dispensing, tire storage/ servicing, lubrication stations, paint booths and a bus wash station. The mechanical design scope included plumbing, fire protection, HVAC, controls and process systems and services. The building was designed to reduce energy and water demand and includes for rainwater storage facilities.

The electrical scope included normal and emergency power systems, fire alarm, state-of-the-art LED lighting and integrated IT System (incorporating time management, clock system, Presto system, communication systems and various radio systems). Durham Region building standards also required design of a lightning protection scheme.

SERVICES

Mechanical Engineering | Electrical Engineering | IT | Security and Communications Design | Lighting Design

PROJECT FEATURES

Size: 60,000 ft2 - 5500 m2 | Status: Completed 2016

LOCATION

Oshawa, Ontario

KEY SCOPE ELEMENTS

State of the art ventilation and exhaust | Controls & process systems and services | Additional design for lighting protection scheme | Energy use reduction strategies | Rainwater storage | Designed to achieve LEED Silver

Gas Drive

Slave Lake Pulp 9 MWe Cogeneration Project

Waste-activated sludge is produced in vast amounts at pulp mills, and is generally sent to be incinerated or landfilled, or can be land applied. Any of these options represented a lost opportunity at the Slave Lake Pulp plant in Alberta. The sludge would instead be repurposed to serve as the main ingredient for anaerobic digestion—a reliable, local, ongoing source of renewable energy.

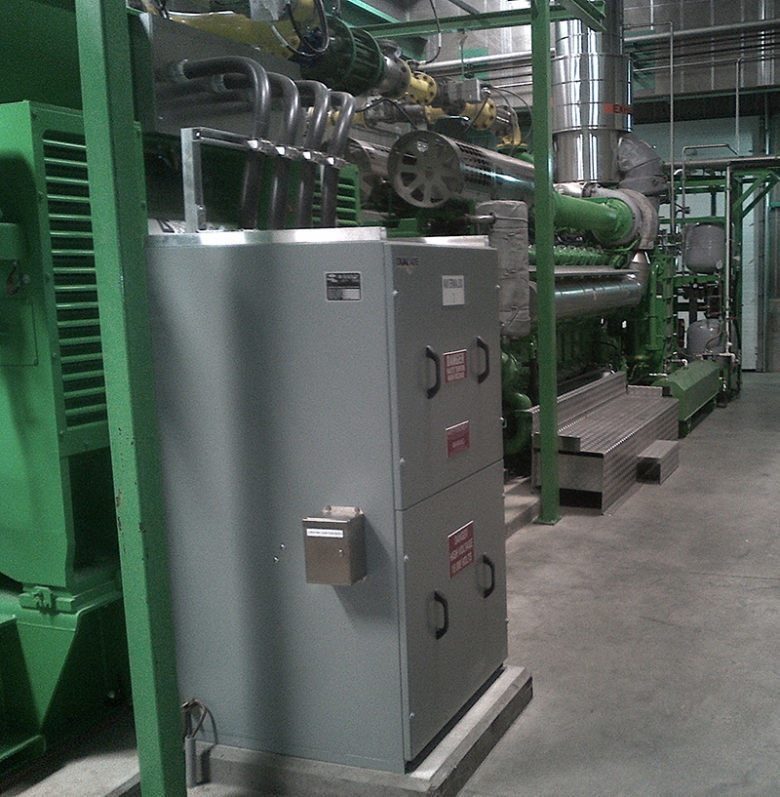

HH Angus designed a 3 X 3 MWe bio-gas fed cogeneration plant for Slave Lake Pulp, a division of West Fraser Mills. The renewable energy technology integrates energy-efficient anaerobic digestion, using the pulp sludge, into the plant’s existing wastewater treatment system. This allows the plant to generate a methane-rich biogas that produces electricity and heat for the pulping process.

Our scope included: engineering electrical power equipment to integrate from the owner’s 13.8kV switchboard into the electrical generation system distribution to connect the cogeneration equipment; electrical design for a new engineered building housing the cogeneration machines and balance of plant; affiliated balance of plant engine electrical support services, such as high and low temperature cooling, exhaust gas heat exchanger and fresh/waste oil, glycol makeup systems, etc.

HH Angus prepared a 13.8kV single line diagram for the electrical system, from the power generation modules through the switchboards, to the interface to the utility service and existing owner’s distribution system; plus preparation of a 600V & 120/208V single line diagram for the generator, building auxiliary and balance of plant services. We also designed protection and control systems, and connection arrangements including SCADA with AESO.

SERVICES

Electrical Engineering | Commissioning support

PROJECT FEATURES

Status: Completed 2015

LOCATION

West Fraser Mills, Alberta

KEY SCOPE ELEMENTS

Designed a 3 X 3 MWe bio-gas fed cogeneration plant | Detailed design of power equipment to integrate to utility and owner’s existing plant | Initiated protection and control system designs Including connection arrangements - SCADA with AESO

Proven protection

We provided a detailed short circuit analysis and co-ordination protection setting study to satisfy the owner that their system is fully protected.

Energy win-win

“This system will now allow us to actually take advantage of some of this lost energy, while also reducing our consumption.”*

Rod Albers, Manager of Energy ad Bio-Product Development, West Fraser Mills